Mold powder for continuous casting of low nickel and high manganese stainless steel and preparation method thereof

A continuous casting mold slag and stainless steel technology, applied in the field of continuous casting mold slag, can solve the problems of reducing the viscosity of the mold slag, increasing the unit consumption of the mold slag, and achieving the effects of reducing the amount of grinding, preventing slag inclusion, and avoiding vibration marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0027] In this embodiment 1-3, the weight percentage distribution ratio of the chemical components, physical properties, and use effects of the mold flux are compared with the existing comparative examples 4 and 5.

[0028] Table 1 is the comparison between the mold flux of this embodiment 1-3 and the existing mold flux 4-5

[0029]

[0030]

[0031] Note: The sum of the chemical components of mold flux is less than 100%, and the rest is the content of impurity elements.

[0032] ●No longitudinal cracks; only shallow vibration marks at the corners of the slab; no slag inclusions on the surface of the slab.

[0033] ▲Small longitudinal cracks occasionally appear; the depth of vibration marks on the surface of the slab is average; and slag inclusions occasionally appear.

[0034] ※There are longitudinal crack defects; the depth of vibration marks on the surface of the slab is relatively deep; there are many slag inclusion defects.

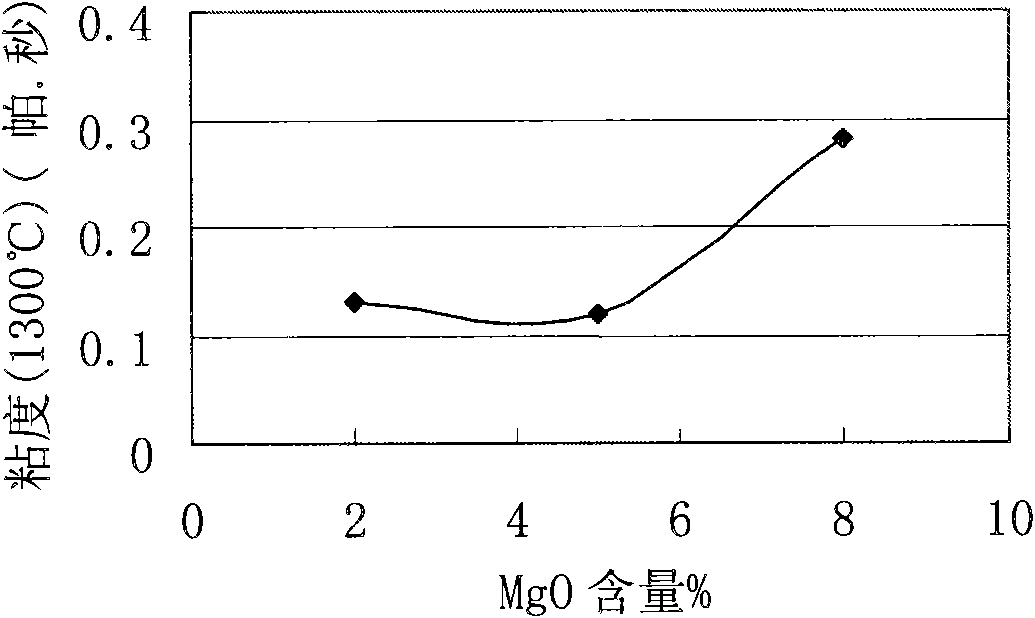

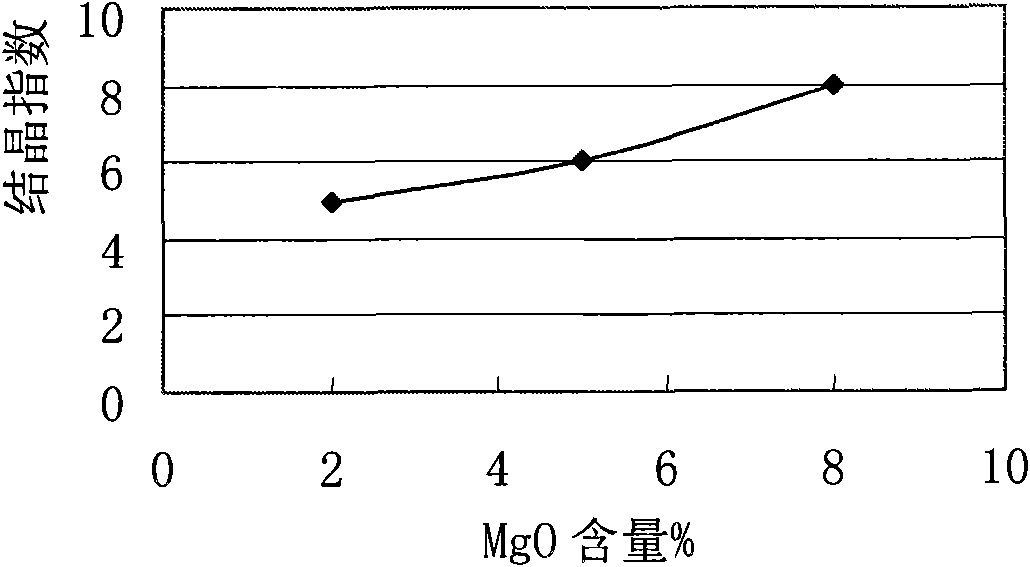

[0035] The addition of MgO and MnO chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com