Arc-extinguishing commutation switch and manufacture method thereof

A technology for commutation switches and manufacturing methods, which is applied to high-voltage/high-current switches, electric switches, high-voltage air circuit breakers, etc., and can solve the problems of failing to meet the needs of production, burning out arc switches, and failing to ensure short-circuit connection between columns and short-circuit blocks and other problems, to achieve the effect of reliable contact, large contact area and small arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

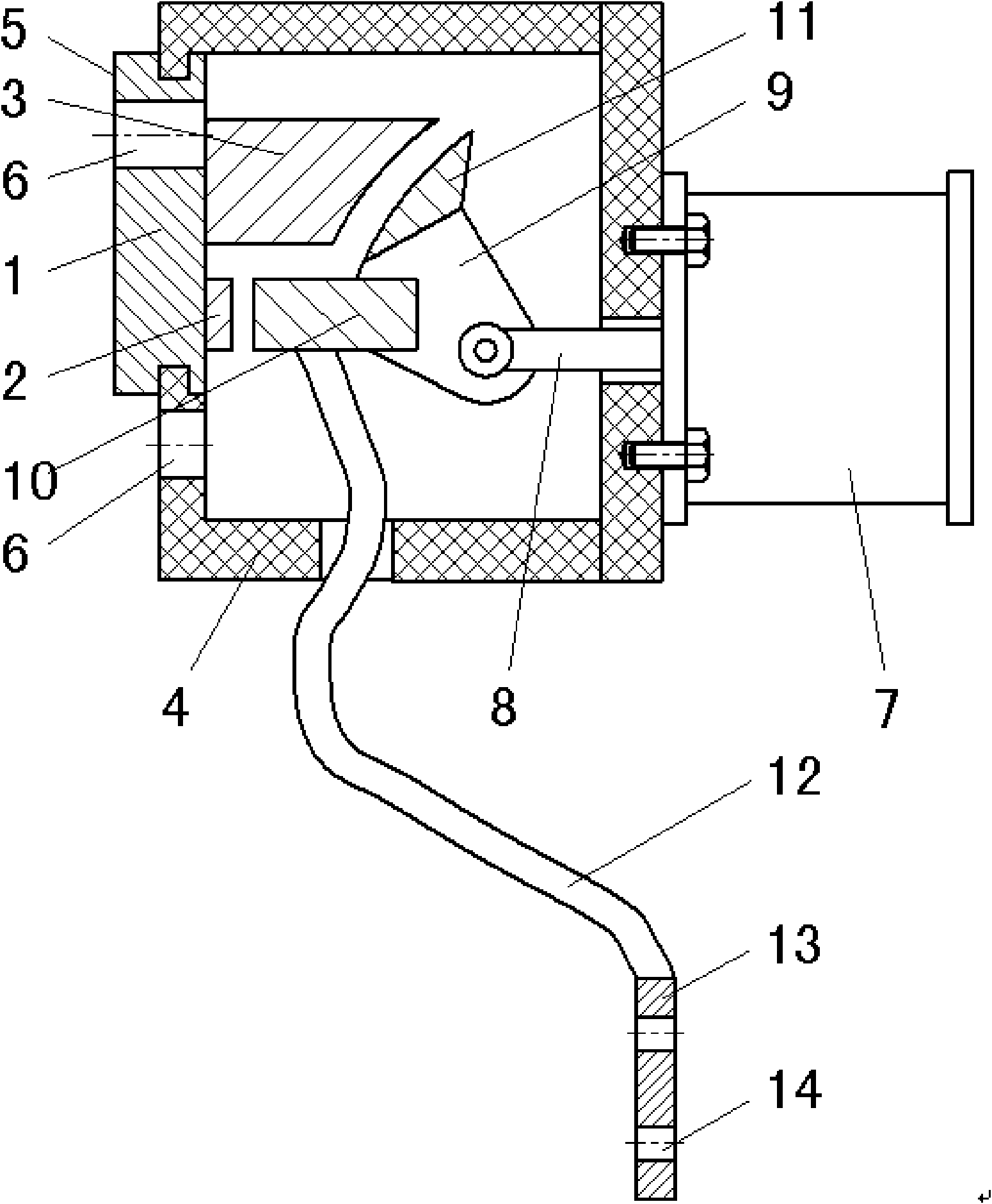

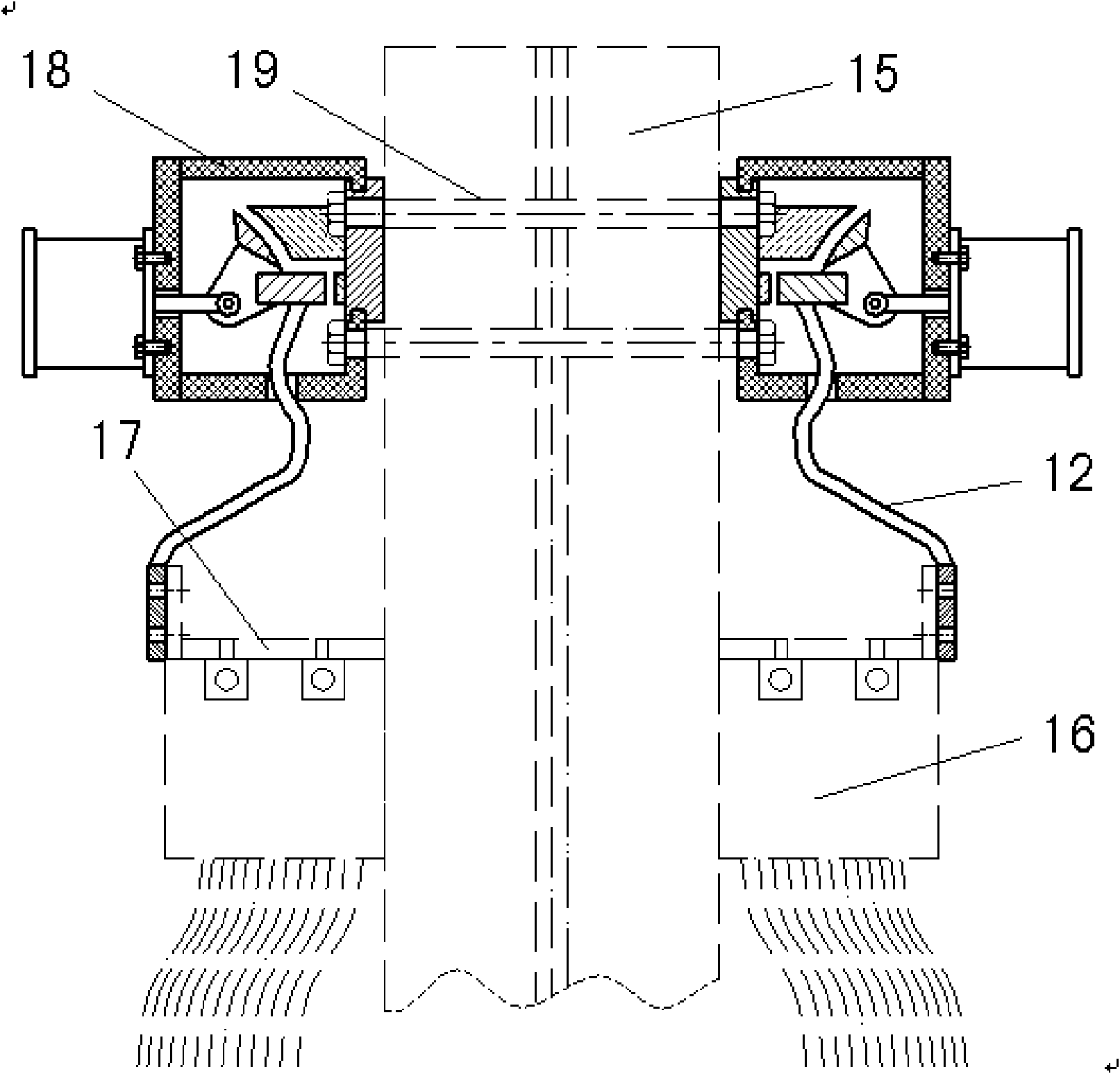

[0014] Embodiments of the present invention: the manufacturing method of the arc-extinguishing commutation switch of the present invention is as follows figure 1 shown. The method is to use a piece of high-conductivity cubic material as the static contact base 1, and weld a static main contact 2 and a static arc contact 3 on the same surface of the static contact base 1; the model is 3240 Or N350 epoxy phenolic pressed glass cloth board to make an arc extinguishing cover 4, cover the arc extinguishing cover 4 outside the static main contact 2 and the static arc contact 3, the edge of the arc extinguishing cover 4 and the static contact base For fixed connection, make a crimping surface 5 on the other side of the static contact base 1. The crimping surface 5 is used for crimping with the column 15 of the aluminum electrolytic cell. The crimping surface 5 should be higher than the arc extinguishing cover 4. The bottom plane is exposed outside the arc chute 4; in order to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com