Preparation method of simulated oil in indoor oil displacement experiment and application thereof

A technology of experimental simulation and simulation of oil, which is applied in the direction of educational appliances, teaching models, instruments, etc., can solve the problems affecting the experimental results, etc., and achieve the effect of simple raw materials, stable performance and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] [embodiment 1] preparation of simulated oil

[0010] Accurately measure 3500mL of PAO base oil A (viscosity of 140mPa·s at 65°C) in a 1L beaker, then measure 1500mL of PAO base oil B (viscosity of 20mPa·s at 65°C) and slowly transfer it to the beaker with a glass rod. Place the beaker in a 65°C water bath, and slowly add 2g of tackifier dropwise. If the viscosity enhancer has poor fluidity, it can be left to stand in a 65°C water bath for 2 hours before adding. The prepared simulated oil was placed in a water bath at 65°C for 1 hour, and stirred slowly with a glass rod to prevent local overheating. Then, under the condition of constant temperature of 65° C., the mixture was mechanically stirred at a speed of 120 rpm for 1.5 hours. The final viscosity is 78 mPa·s, and the rate of change of viscosity is 1% after being placed in an incubator at 80° C. for 96 hours.

Embodiment 2

[0011] [embodiment 2] preparation of simulated oil

[0012] Accurately measure 4000mL of PAO base oil B (viscosity of 140mPa·s at 65°C) in a 1L beaker, then measure 1000mL of PAO base oil B (viscosity of 20mPa·s at 65°C) and slowly transfer it to the beaker with a glass rod. Place the beaker in a 65°C water bath, and slowly add 1g of tackifier dropwise. If the viscosity enhancer has poor fluidity, it can be left to stand in a 65°C water bath for 2 hours before adding. The prepared simulated oil was placed in a water bath at 65°C for 1 hour, and stirred slowly with a glass rod to prevent local overheating. Then, under the condition of constant temperature of 65° C., the mixture was mechanically stirred at a speed of 150 rpm for 2 hours. The final viscosity is 80.5 mPa·s, and the viscosity change rate is 1.5% after being placed in an incubator at 80° C. for 96 hours.

Embodiment 3

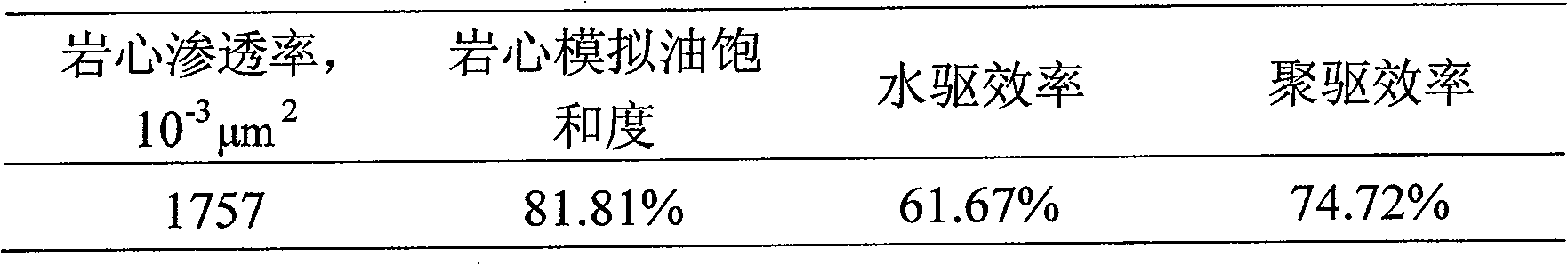

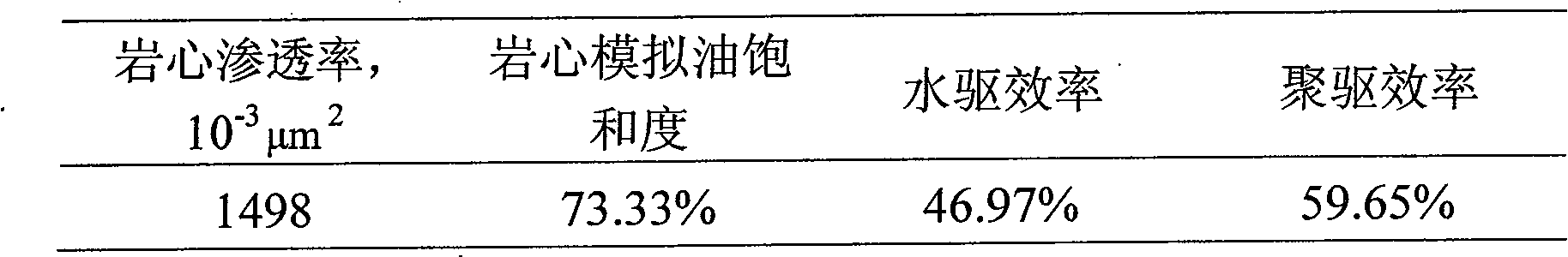

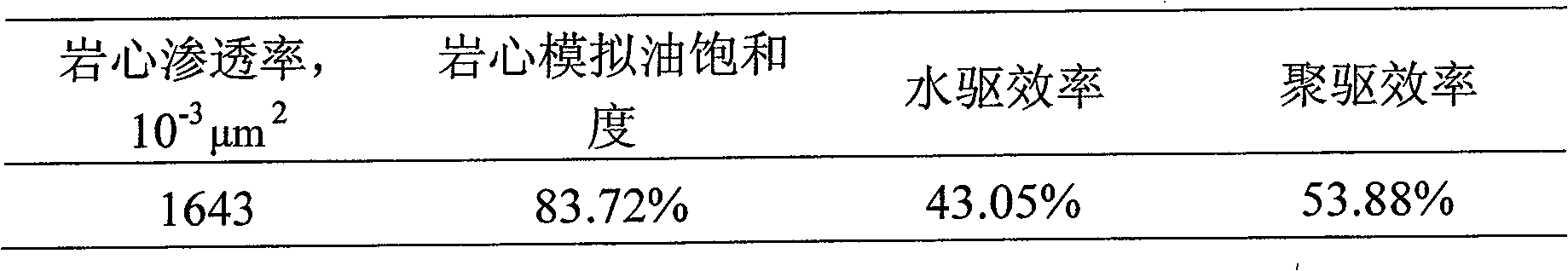

[0013] [Example 3] Simulated oil applied to sand-packed pipe flooding experiment

[0014] The injection water used in the water flooding experiment is simulated formation water (total salinity is about 10000mg / L), and the polymer used in the polymer flooding experiment is the hydrophobic association polymer P(AM-NaAA-C 16 DMAAC), the concentration is 1750mg / L. The simulated oil used has a viscosity of 78 mPa·s at 65°C. Sand filling pipe size: diameter 2.5cm, length 55cm. During the whole experiment, the constant temperature of the incubator and pipe fittings was 65°C. The core parameters and oil displacement efficiency are as follows: (the simulated oil saturation is used to indicate the percentage of simulated oil in the reservoir rock pores; the water flooding efficiency indicates the amount of oil recovered from the unit pore volume swept by the injected water. The oil reserves per unit volume swept by water at the beginning of water injection; polymer flooding efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com