Drying technique of viscous strain material and equipment thereof

A drying process and material technology, applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problem that the drying effect is not very ideal

Active Publication Date: 2010-11-10

湖南豫园生物科技股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For viscous bulk materials, the drying effect is not very ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

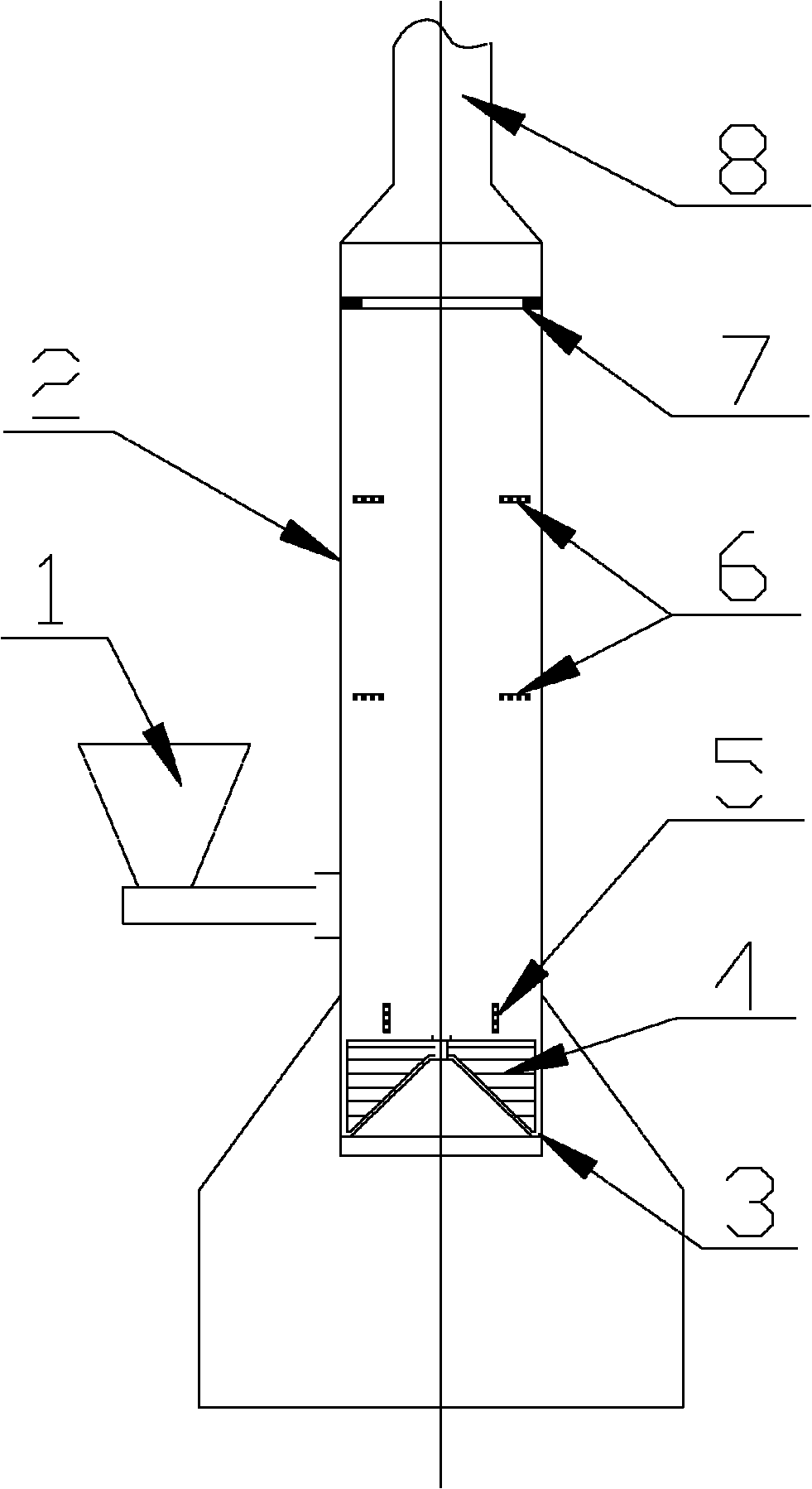

The invention discloses a drying technique of a viscous strain material and equipment thereof. The equipment is characterized in that a colliding grid (5) and a turbulent flow grid (6) are additionally arranged above the inner wall of a main pipe tower (2) and a crusher (4) so as to lead the dried material to collide with the colliding grid for being fined, simultaneously the dried fine particle material prolongs the exchange time of the wet material and high-temperature hot air by the buffering effect of the turbulent flow grid (6) in the main pipe tower, thus achieving the effect of improving vaporization and dehydration. The technique process is as follows: the obtained viscous strain material by the membrane concentration technique and the hot air are simultaneously delivered into thedried main pipe tower (2) for crushing and drying to form particles; and the particle powder enters a whirlwind material receiving machine (11) by an air-inducing pipe (8) for separation and collection of products. The invention can fast improve the dehydration effect of materials, has good viscous-material drying effect and high drying efficiency, effectively guarantees active components of the strain, and has low energy consumption, large drying strength, noncaking finished products and high yield.

Description

A drying process and equipment for viscous fungus material technical field The invention relates to a process for drying sticky wet materials containing bacteria species and equipment for the process. Background technique Among the currently widely used drying methods for water-containing materials, the drying effect of vacuum drying, freeze drying and hot air circulation oven is not ideal. Not only is the drying uneven, easy to agglomerate, low efficiency and long drying time, but also manual operation is required for feeding and discharging materials. , Susceptible to pollution, harsh operating environment. Freeze-drying and vacuum-drying, which are widely used in the fields of pharmaceuticals and bioengineering, require large-scale equipment, and it is difficult to adopt continuous production steps, making the production method cumbersome and laborious. Spray drying is a relatively advanced drying equipment at present, but the existing technology and equipment have a l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F26B3/08B02C23/08

Inventor 朱力山林木森曹宝玲刘建平谭欢

Owner 湖南豫园生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com