An engine gas distribution system with electro-hydraulic integrated control

A comprehensive control and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as difficult to adjust valve overlap angle, easy wear, complex structure, etc., to achieve optimized engine performance, flexible control, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

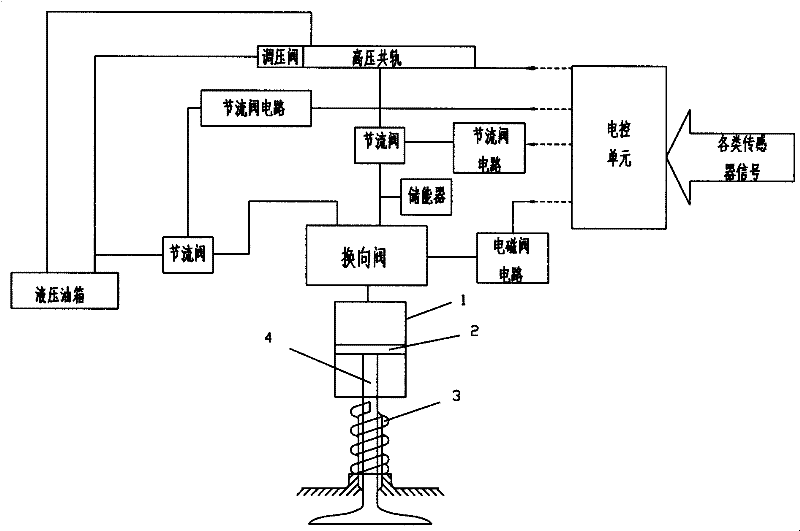

[0020] attached figure 1 It is a structural diagram of the present invention, it has a hydraulic cylinder 1, the piston rod 4 of the hydraulic cylinder is connected with the valve stem, and a pressure spring 3 is housed and connected with the valve stem. The oil circuit of the hydraulic cylinder is connected with a reversing valve, which is a 2-position 3-way valve, and is connected with the electronic control unit through a solenoid valve circuit. One of its valve positions is connected with the high-pressure oil circuit, and the other valve position is connected with the low-pressure circuit. A throttle valve is arranged on the high-pressure oil circuit, and the throttle valve is connected with the electronic control unit through a throttle valve circuit. An accumulator communicates with it on the oil circuit between the throttle reversing valves. The high-pressure oil route is powered by the high-pressure common rail system of the diesel engine, and has a pressure regulat...

Embodiment 2

[0023] attached figure 2 It is a kind of structure schematic diagram of the present utility model, and it has a hydraulic cylinder 1 similarly with embodiment 1, and the piston rod 4 of hydraulic cylinder links to each other with valve stem, and a pressure spring 3 is housed and connected on the valve stem. The oil circuit of the hydraulic cylinder is connected with a reversing valve, which is a 2-position 3-way valve, and is connected with the electronic control unit through a solenoid valve circuit. One of its valve positions is connected with the high-pressure oil circuit, and the other valve position is connected with the low-pressure circuit. A throttle valve is arranged on the high-pressure oil circuit, and the throttle valve is connected with the electronic control unit through a throttle valve circuit. An accumulator communicates with it on the oil circuit between the throttle reversing valves. A throttle valve is arranged on the low-pressure oil circuit, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com