Pile-forming method for cement paste spraying multi-directional core entraining mixing pile

A technology of mixing piles and cement slurry, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of limited strength improvement of soft soil layers, waste of pile body materials, and uneconomical problems, and achieves low construction costs and low pile construction costs. Reasonable physical force and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

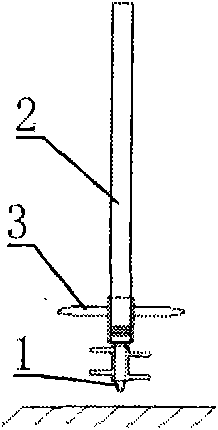

[0036] figure 1 Marking description: drill bit 1, drill rod 2, drill blade 3.

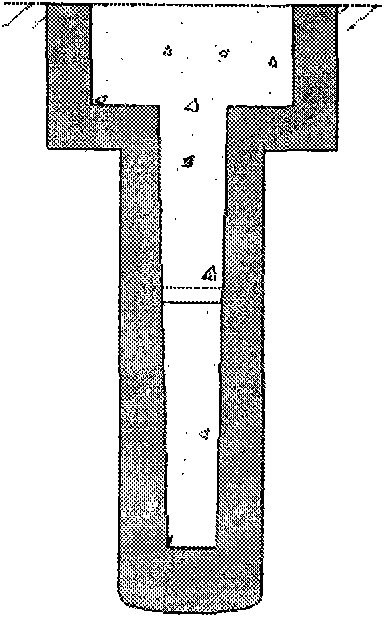

[0037] Image 6 Description of marking: core pile 4.

[0038] The construction steps of the embodiment of the cement slurry spraying multi-directional cored stirring pile forming method of the present invention are as follows:

[0039] ①. Put the multi-directional core-filling mixing pile machine in place, level it, and align the drill bit 1 with the pile position (such as figure 1 );

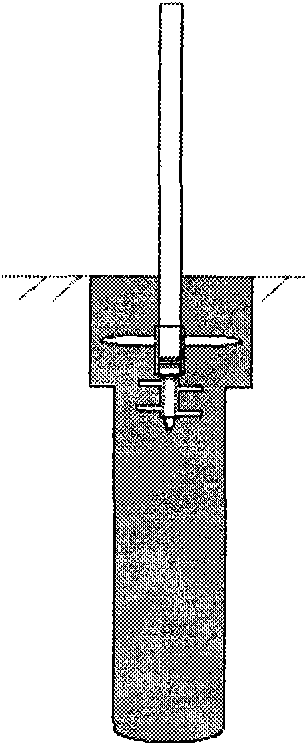

[0040] ②, start the mixer, make the drill pipe 2 mix the cut soil downward along the guide frame (such as figure 2 ), simultaneously open the slurry delivery pump to spray cement mortar to the soil, the slurry volume is 90% of the total slurry volume, and the drill bit blades 3 rotate forward and reverse at the same time to stir until the design depth;

[0041] ③. After reaching the predetermined design depth, continue spraying and stirring at the pile end for more than 10 to 30 seconds (such as image 3 ), s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com