Small cylinder stretching device

A stretching device, a small technology, applied in the field of forming and manufacturing, can solve the problems of high cost, low qualification rate, difficult processing, etc., and achieve the effects of low cost, easy operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

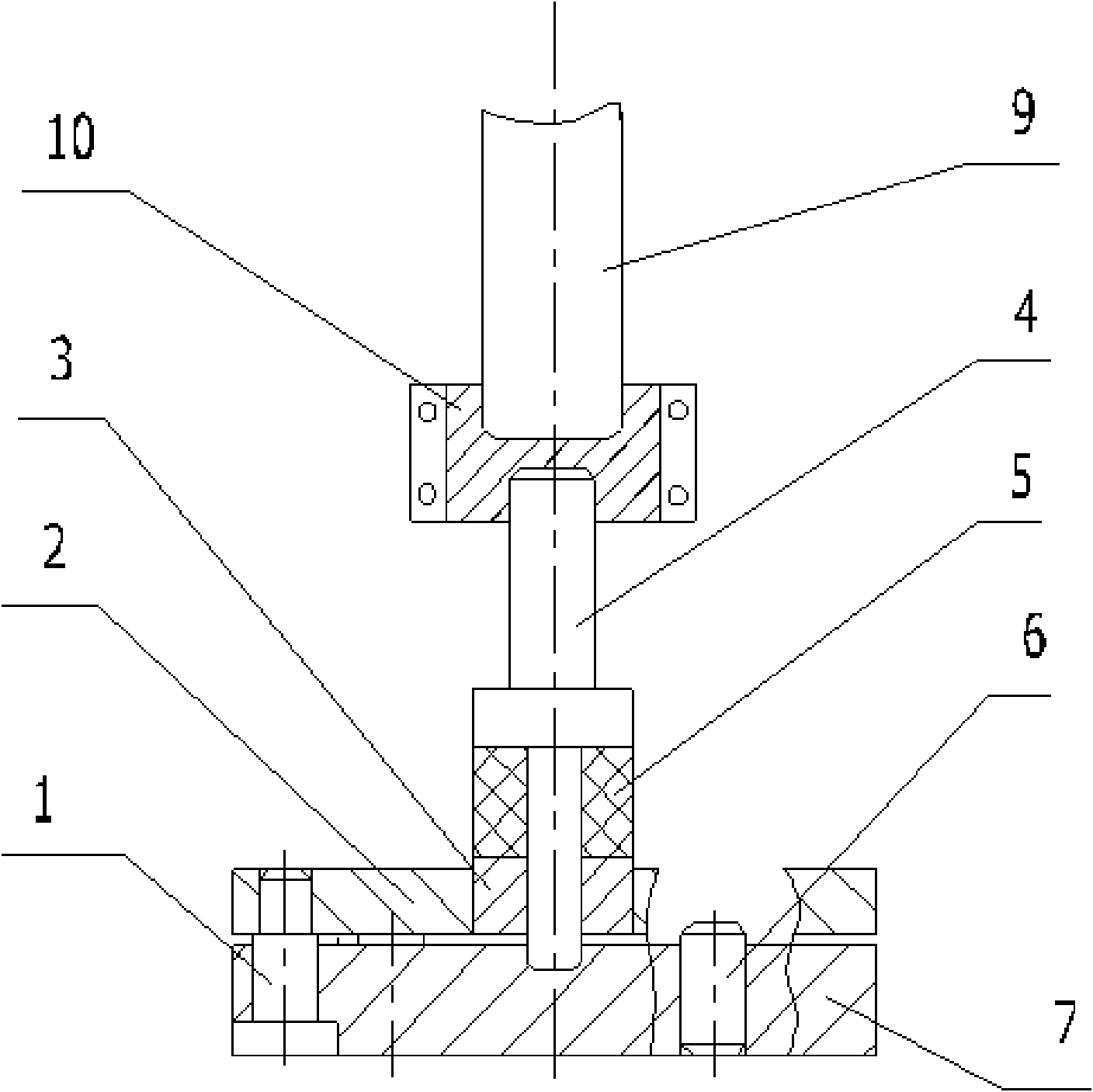

[0037] First, process each component required in this embodiment:

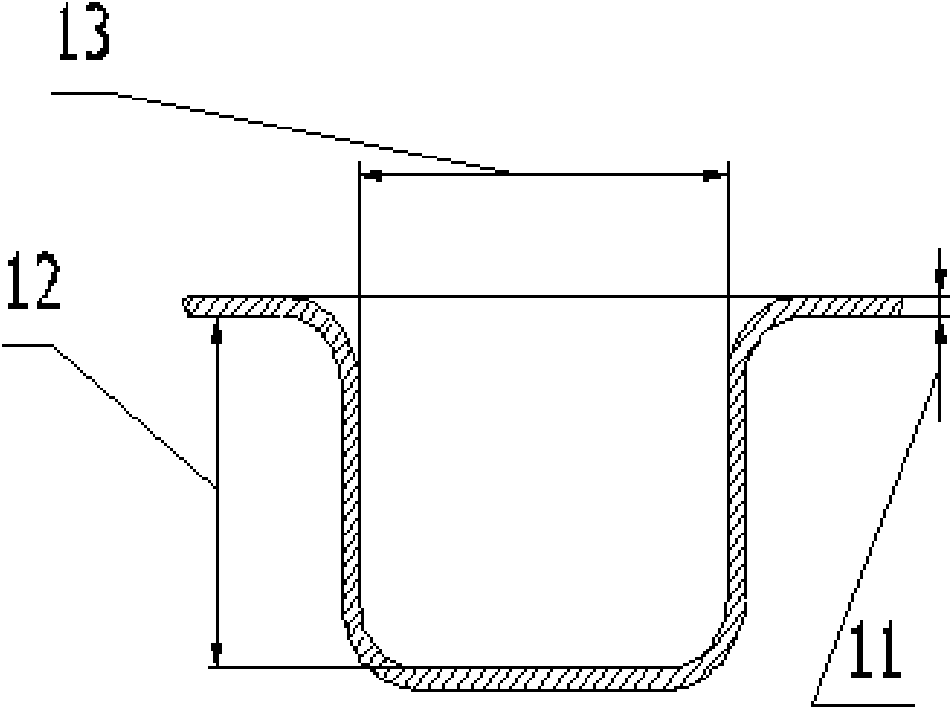

[0038] Making the stretching punch rod 4: design the outer surface of the head of the stretching punch rod 4 according to the required stretched shape structure of the stretched part 8; the handle of the stretching punch rod 4 is the force end, Used to withstand the pressure exerted by external forces;

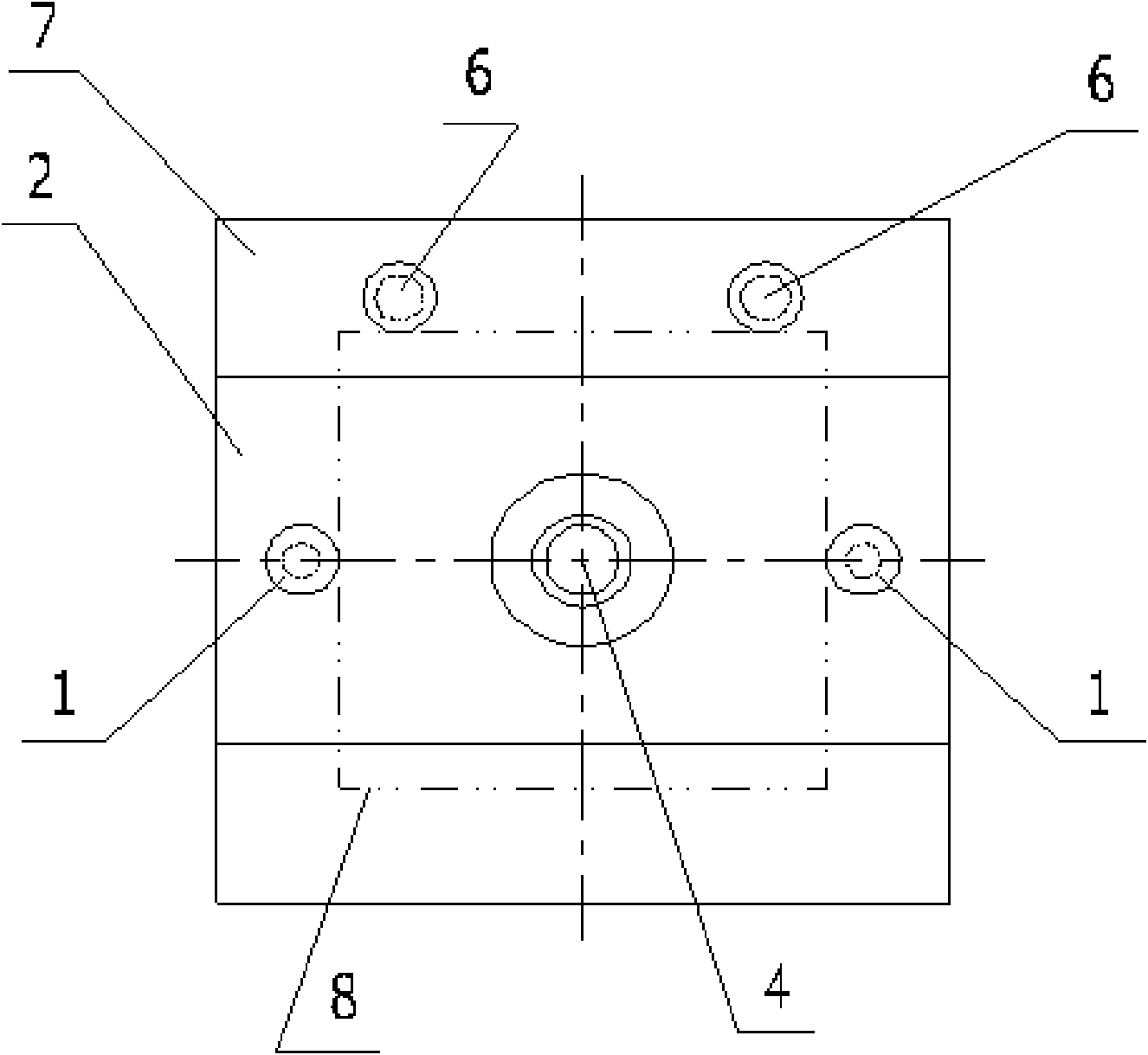

[0039]Make the positioning guide plate 2 and the concave template 7: set the positioning guide opening on the positioning guide plate 2, the diameter of the positioning guide opening is greater than the head outer diameter of the stretching punch rod 4, preferably the head of the stretching punch rod 4 The part can be matched with the positioning guide opening of the positioning guide plate 2; a cavity is provided on the concave template 7, and the structure of the cavity is matched with the structure of the outer surface of the head of the stretching punch rod 4, and the concave template 7 is installed on the...

Embodiment 2

[0045] In this embodiment, a pre-tightening structure is added on the basis of the first embodiment. In this embodiment, the positioning block 3 and the pre-tightening pad 5 are used to form a pre-tightening structure, so that the parts to be stretched can be solved during the stretching process. Go over the wrinkle problem.

[0046] First, improve the processing of the existing components in the first embodiment: on the basis of the processing described in the first embodiment, the stretching punch rod 4 is provided with a bump between the head and the shank. The shape of the block is preferably ring-shaped; the positioning guide plate 2 is processed so that it can fit with the positioning block 3 clearances.

[0047] Next, process the newly added pre-tightening structure: 1. Set up a positioning hole on the positioning block 3. The aperture of the positioning hole is larger than the outer diameter of the head of the stretching punch rod 4. The positioning block 3 needs to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com