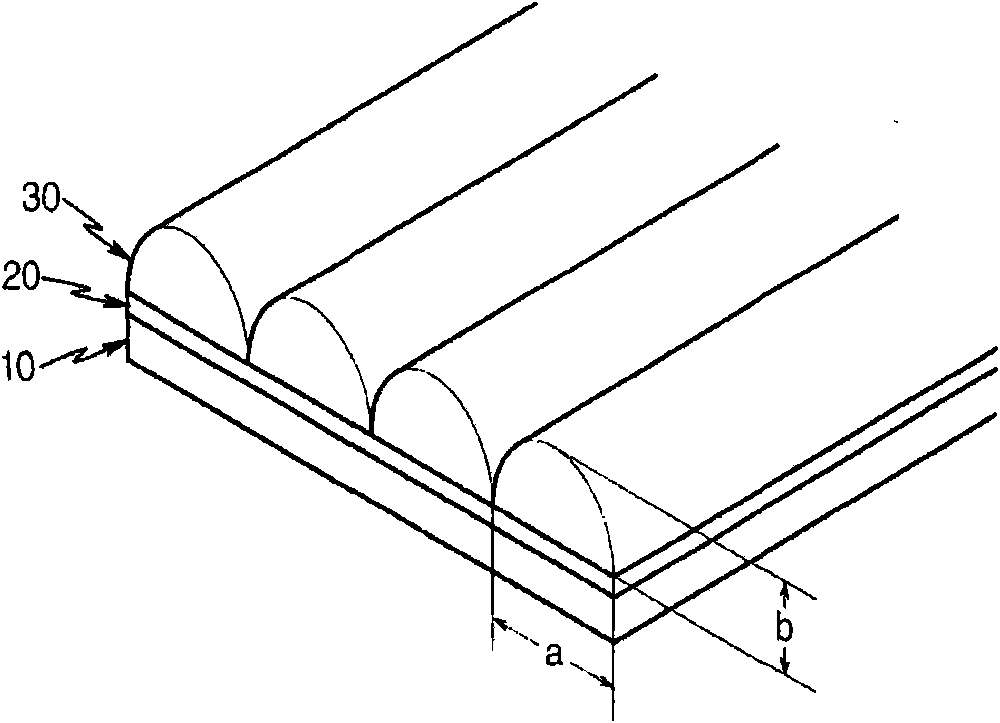

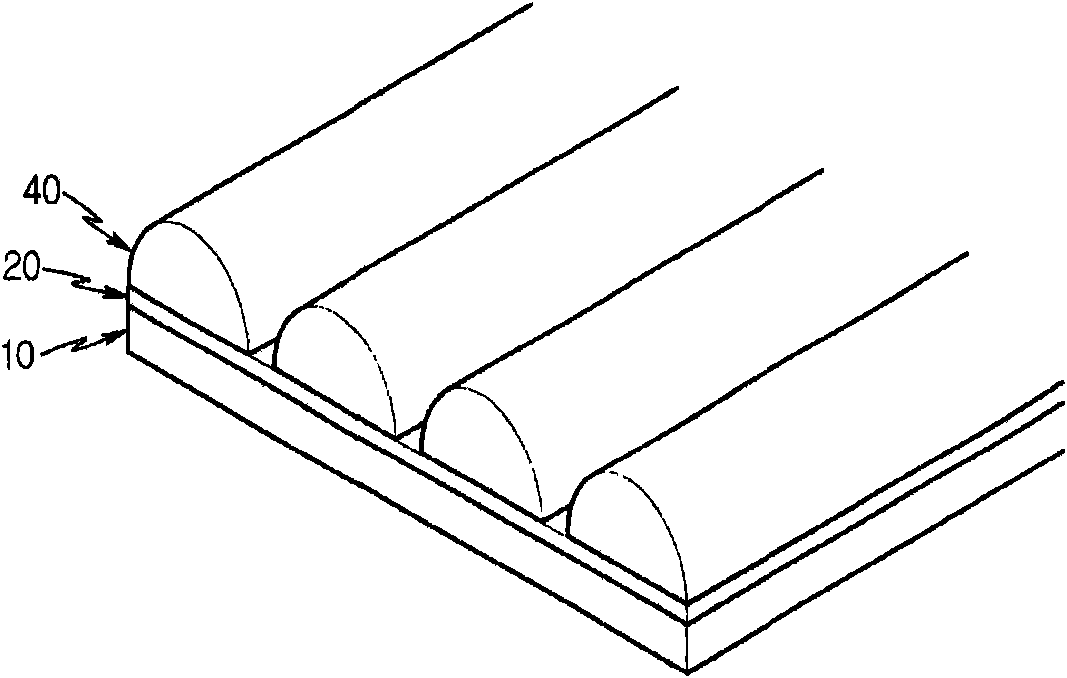

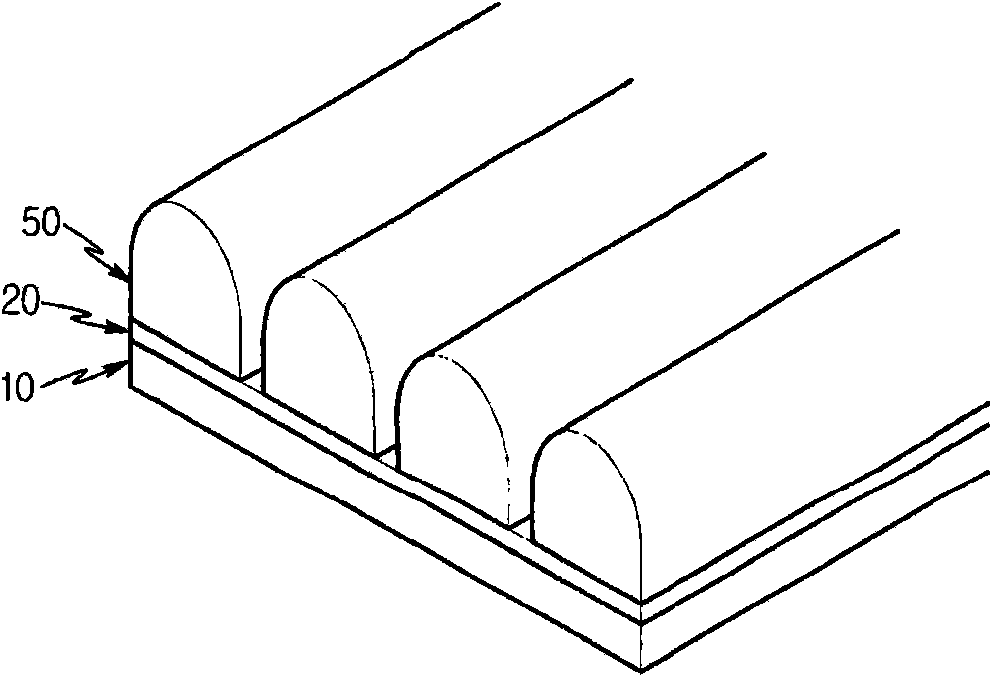

Diffusion plate

A technology of light diffusing plate and polystyrene resin, applied in instruments, optics, diffusing elements, etc., can solve the problems of reducing productivity and increasing manufacturing cost, and achieve the effect of sufficient brightness, reduced use, and excellent shading properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 12

[0075] The components and composition ratios of Examples 1 to 12 are shown in Table 1 below.

[0076] The polycarbonate resin used had a melt index (MI) defined in accordance with ASTM D1238 of 22 grams per 10 minutes (22 g / 10 min) under the conditions of 300° C. and a load of 1.2 kg.

[0077] In these examples, such as the base resin, when polycarbonate and polystyrene are used in the form of a mixture, they are added in the composition ratio shown in Table 1, and then melted at 250°C using a twin-screw extruder mixed.

[0078] The polystyrene resin used had a melt index (MI) defined in accordance with ASTM D1238 at 200° C. and a load of 5 kg at 1.5 grams per 10 minutes (1.5 g / 10 min).

[0079] As the base resin used for the surface layer, a typical styrene-acrylic acid copolymer resin in the composition of Table 1 was used.

[0080] In the composition of the light diffusion plate, the base layer is composed of a base resin and a light diffusion agent in the composition of ...

Embodiment 13 to 18

[0097] The light-diffusing plate was produced in the same manner as in Examples 1 to 12, and was produced in the same size. In addition, only polystyrene resin (glass transition temperature 115° C.) in which acrylic acid is partially copolymerized is used as the base resin of the base layer, and in Examples 15 and 16, the surface layer is formed on one side of the base layer. On the surface, and in Examples 17 and 18, the surface layer is formed on both surfaces of the base layer

[0098] The specific compositions of the light diffusing plates of Examples 13 to 18 are shown in Table 3 below.

[0099] 【table 3】

[0100]

[0101]

[0102] The total light transmittance, haze, brightness, curl, water absorption, and heat distortion temperature of the light diffusion plate thus obtained were measured. The measurement results are shown in Table 4 below.

[0103] 【Table 4】

[0104] implement

[0105] It can be clearly seen from Table 4 that in the embodiment of us...

Embodiment 19 to 24

[0107] The light diffusing plate was manufactured in the same manner as in Examples 1 to 12, and was manufactured in the same size, except that, in terms of the type of diffusing particles, silicon particles were used instead of acrylic resin particles, and in Examples 21 and 22 In Examples 23 and 24, the surface layer was formed on one surface of the base layer, and in Examples 23 and 24, the surface layer was formed on both surfaces of the base layer.

[0108] The specific compositions of the light diffusing plates of Examples 19 to 24 are shown in Table 5 below.

[0109] 【table 5】

[0110]

[0111] The total light transmittance, haze, brightness, curl, water absorption, and heat distortion temperature of the light diffusion plate thus obtained were measured. The measurement results are shown in Table 6 below.

[0112] 【Table 6】

[0113]

Example

Total transmittance

(%)

(%)

brightness

(cd / m 2 )

Curl

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com