Heat-insulating absorption refrigeration circulating device

A refrigeration cycle and adiabatic technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing mass transfer space and time, increasing initial investment and power consumption, and limiting the absorption effect of absorbers. Contact area, increase the space and time for mass transfer, and improve the efficiency of the refrigeration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

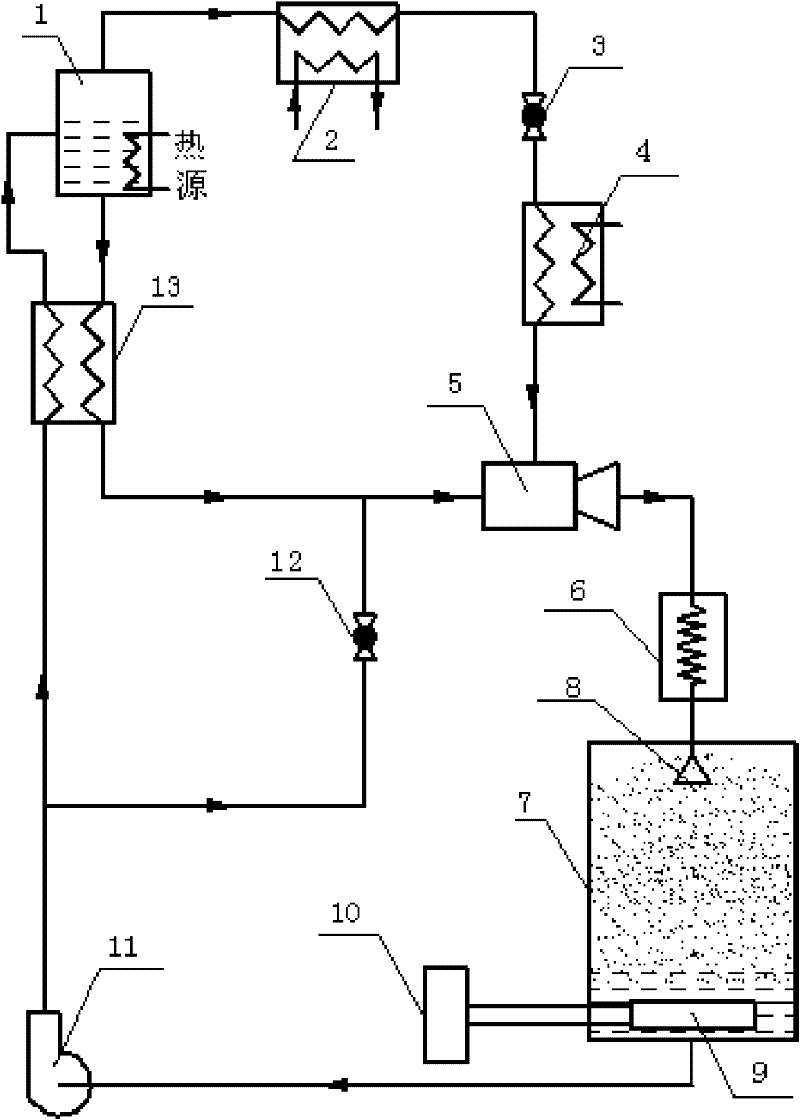

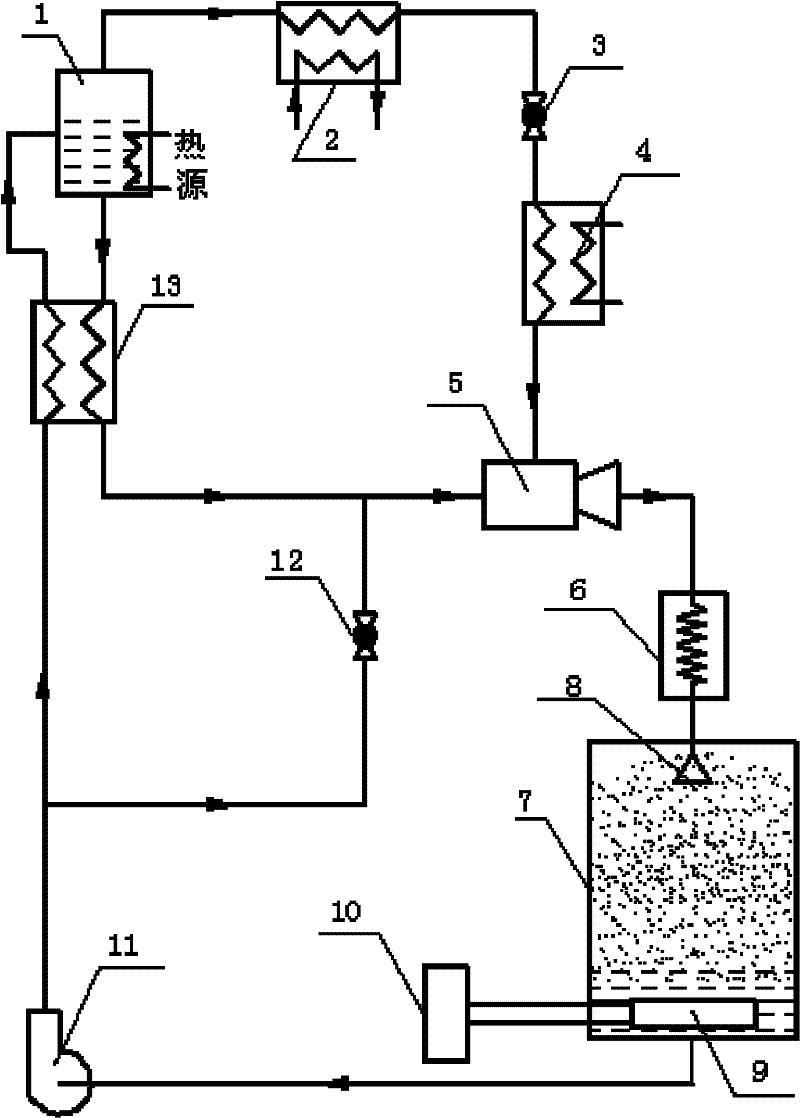

[0013] exist figure 1 Among them, an adiabatic absorption refrigeration cycle device includes a generator 1, a condenser 2, an evaporator 4, an adiabatic absorber 7, a solution pump 11 and a two-phase flow ejector 5, and the solution outlet of the generator 1 is connected to the solution heat The high-temperature side solution inlet of the exchanger 13 is connected, the high-temperature side solution outlet of the solution heat exchanger 13 is connected with the working fluid inlet of the two-phase flow injector 5, and the outlet of the two-phase flow injector 5 is connected with the inlet of the solution pump 11, and the solution The outlet of the pump 11 is divided into two paths, one path is connected with the solution inlet of the low-temperature side of the solution heat exchanger 13 , and the other path is connected with the working fluid inlet of the two-phase flow injector 5 through the regulating valve 12 . The solution outlet on the low temperature side of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com