Solar heating system for building with cast-in-situ open-web floor

A fasting floor and heating system technology, applied in the field of energy-saving buildings, can solve the problems of high heating costs, large energy waste, and unreasonable arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

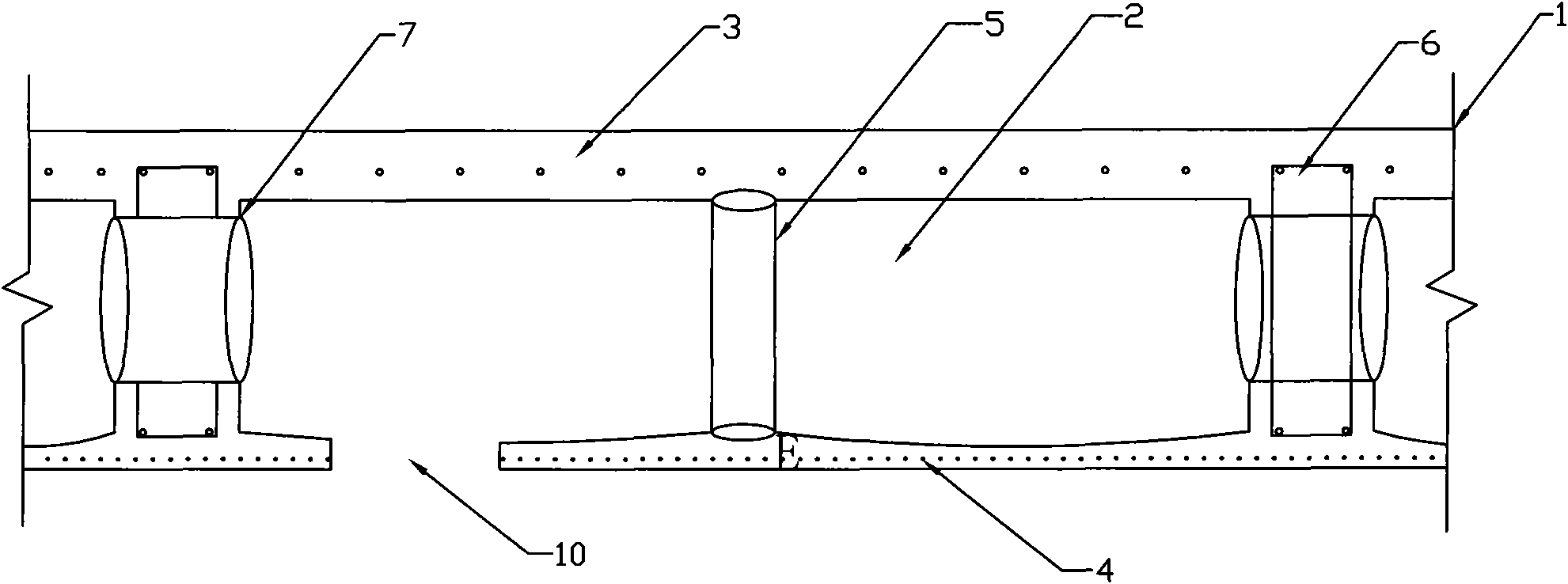

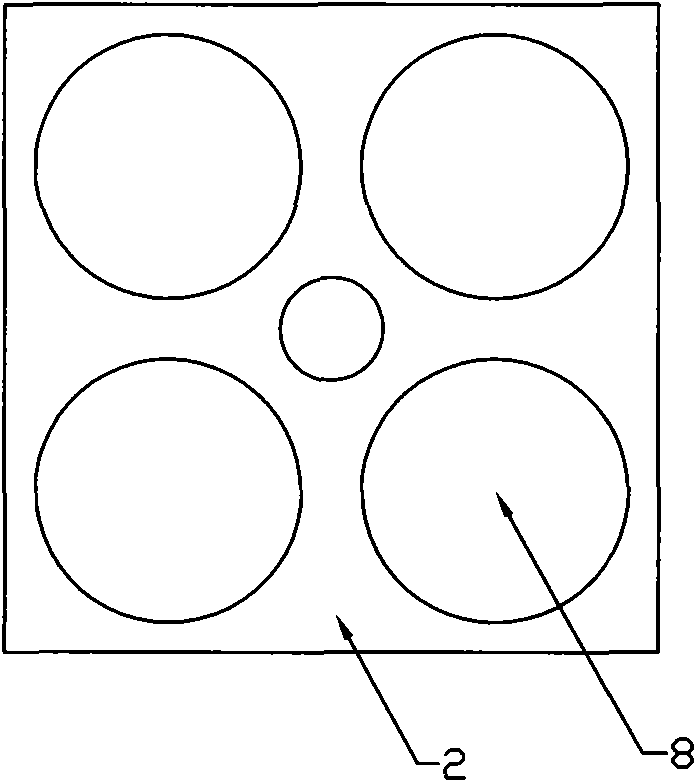

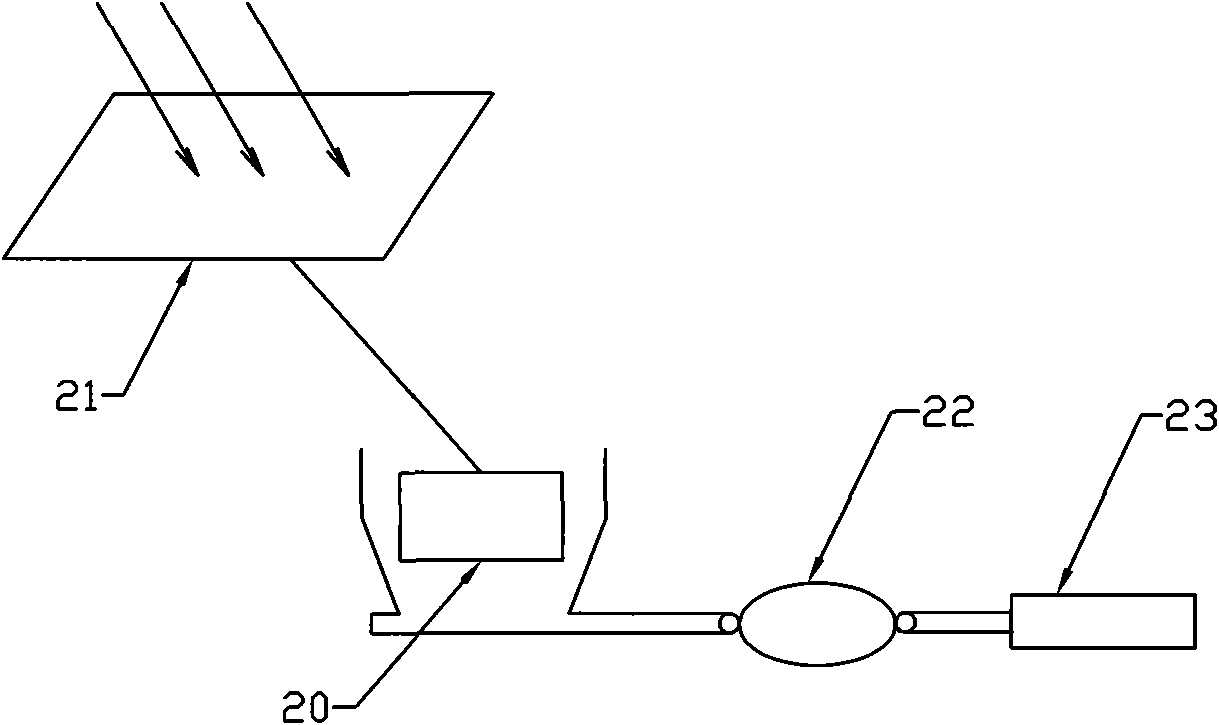

[0024] Such as figure 1 As shown, the schematic diagram of the cast-in-place hollow floor and the thin-walled box inside, the floor 1 includes the thin-walled box 2 in the middle, the upper flange plate 3, the rib beam 6, the lower flange plate 4 and the floor formwork, the thin-walled box There are several wall boxes 2 and they are cast-in-place with composite cement slurry or assembled from plates. An arc, the priority premise is to maintain balance. The bottom plate and the top cover are provided with opposite lower holes and upper holes, the lower holes on the bottom plate are connected with the upper holes on the top cover through a closed through passage 5, and the thin-walled boxes 2 are communicated through a connecting passage 7 installed on the side. A hot air circulation duct is formed inside the whole floor. The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The thin-walled box 2 used in this program can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com