Low-temperature dyeing method for aramid/fire-retardant viscose blended fabric

A technology for flame-retardant viscose and blended fabrics, which is applied in the field of textile printing and dyeing, can solve the problems of not bright color of fabrics, poor fabric homochromaticity, limited color types, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

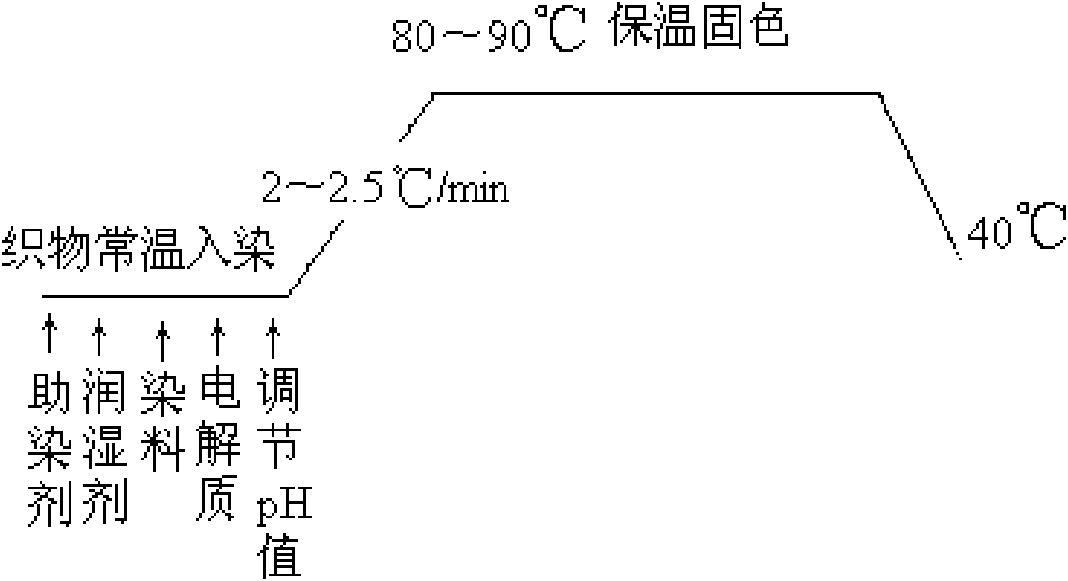

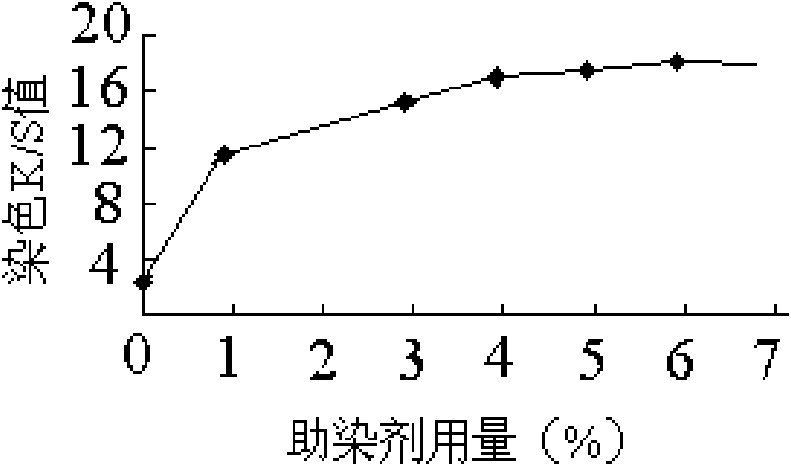

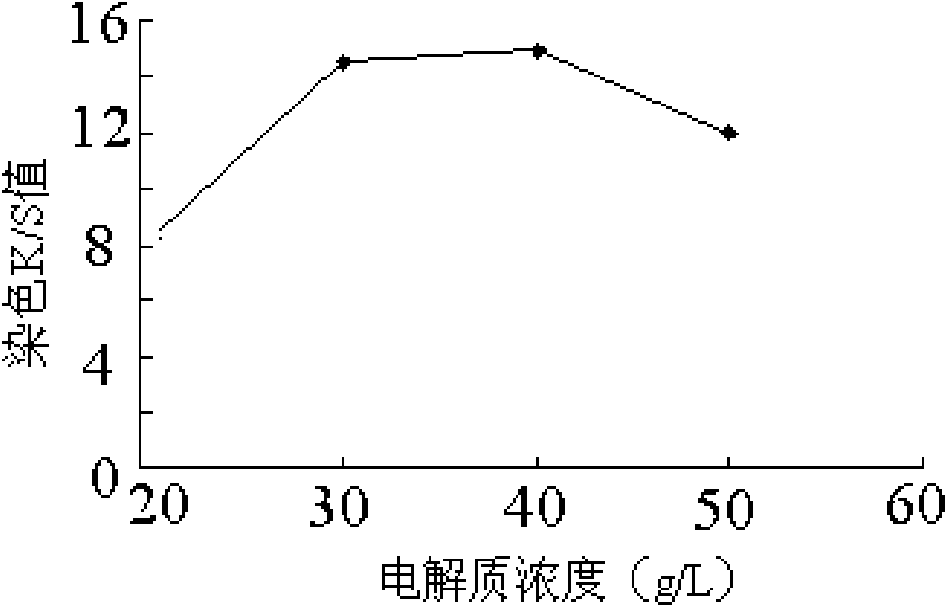

Method used

Image

Examples

Embodiment 1

[0067] Get sodium hydroxide, oil remover DO and water respectively, mix and prepare pretreatment liquid, the concentration of sodium hydroxide and oil remover DO in this pretreatment liquid is respectively 10g / L and 2g / L; Press bath ratio 50: 1. Put the aramid fiber / flame retardant viscose blended fabric to be dyed into the prepared pretreatment solution, and boil it at 80°C for 30 minutes to remove the oil and stains produced during the weaving process, and then , washed with water and dried; respectively taking pyrrolidone and sulfolane at a volume ratio of 6:4 to prepare a dyeing aid. According to the weight of the aramid fiber / flame-retardant viscose blended fabric after pretreatment, according to the weight percentage (owf) of the dye and the fabric, respectively take 3% of Enix Red, 3% of Cibacron Red, and 3% of Cibacron Yellow B3% and remazol blue B3%, and then take the dispersant NNO, NaCl, the prepared dyeing aid and OP-10 respectively, make the mixed solution of the ...

Embodiment 2

[0079] Get sodium hydroxide, degreasing agent DO water respectively, mix and prepare pretreatment liquid, the concentration of sodium hydroxide and degreasing agent DO in this pretreatment liquid is respectively 15g / L and 2.5g / L; Press bath ratio 50: 1. Put the aramid fiber / flame retardant viscose blended fabric to be dyed into the prepared pretreatment solution, and boil it at 90°C for 40 minutes to remove the oil and stains produced by the fabric during the weaving process. After that, Washing and drying; take acetophenone and sulfolane respectively according to the volume ratio of 6:4, and compound them to obtain dyeing aids; Percentage (owf), respectively take Big Enix Red 5%, Cibacron Red B5%, Cibacron Yellow B5% and Remazol Element Blue B5%, respectively take dispersant NNO, sodium sulfate, prepared dyeing aids and fatty alcohol polyoxyethylene ether, the raw materials taken are made into a mixed solution, and acetic acid is added dropwise in the mixed solution to make a...

Embodiment 3

[0081] Take sodium hydroxide, degreasing agent DO and water respectively, mix and prepare pretreatment liquid, the concentrations of sodium hydroxide and degreasing agent DO in this pretreatment liquid are respectively 12.5g / L and 2.25g / L; 50:1, put the aramid / flame retardant viscose blended fabric to be dyed into the prepared pretreatment solution, boil at 85°C for 35 minutes, and remove the oil and stains generated during the weaving process of the fabric, After that, wash with water and dry; according to the volume ratio of 6:4, take pyrrolidone and sulfolane respectively, and compound them to obtain dyeing aids; Percentage (owf), respectively get Big Enix red 4%, Cibacron red B4%, Cibacron yellow B4% and Remazol blue B4%, respectively get dispersant NNO, NaCl, the dyeing aid that makes and OP-10 nonylphenol polyoxyethylene ether, the raw materials taken are made into a mixed solution, and acetic acid is added dropwise to the mixed solution to obtain a dye solution with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com