Preparation method of lead telluride nano crystal and micron crystal

A technology of nanocrystals and lead telluride, applied in chemical instruments and methods, binary selenium/tellurium compounds, single crystal growth, etc., can solve the problems of complex preparation methods and high costs, and achieve simple preparation methods, good crystallinity, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Weigh 9.7 grams of KOH and 10.3 grams of NaOH respectively and put them into a 50ml polytetrafluoroethylene container, then add 0.494 grams of Pb(NO 3 ) 2 and 0.239 g TeO 2 , after mixing evenly, seal the container with a cover; add 0.62 g of reducing agent KBH to another polytetrafluoroethylene container filled with the same quality of KOH and NaOH 4 , mix well and cover tightly.

[0023] 2) Preheat the above two containers in an oven at 180°C for 1.5 hours, and shake the reaction container for about 30 seconds every 20-30 minutes to promote the melting of the mixed alkali and disperse the reactants evenly in the mixed alkali melt in the liquid.

[0024] 3) Mix the reactants in the above two reaction vessels uniformly, and then make it continue to react for 45 minutes under a constant temperature state of 180°C.

[0025] 4) The reaction vessel was taken out from the oven, and naturally cooled to room temperature in air.

[0026] 5) Use hot deionized water to fu...

Embodiment 2

[0030] 1) Weigh 19.4 grams of KOH and 20.6 grams of NaOH respectively and put them into a 100ml polytetrafluoroethylene container, then add 0.494 grams of Pb(NO 3 ) 2 and 0.332 g Na 2 TeO 3 , after mixing evenly, seal the container with a cover; add 0.62 g of reducing agent KBH to another polytetrafluoroethylene container filled with the same quality of KOH and NaOH 4 , mix well and cover tightly.

[0031] 2) Preheat the above two containers in an oven at 180°C for 2 hours, and shake the reaction container for about 30 seconds every 20-30 minutes to promote the melting of the mixed alkali and disperse the reactants evenly in the mixed alkali melt in the liquid.

[0032] 3) Mix the reactants in the above two reaction vessels evenly, and then make it continue to react for 1 hour under a constant temperature state of 180°C.

[0033] 4) The reaction vessel was taken out from the oven, and naturally cooled to room temperature in air.

[0034] 5) Use hot deionized water to ful...

Embodiment 3

[0038] Step is the same as example 1, and difference is only that the reaction time in step 3) is 1.5 hours.

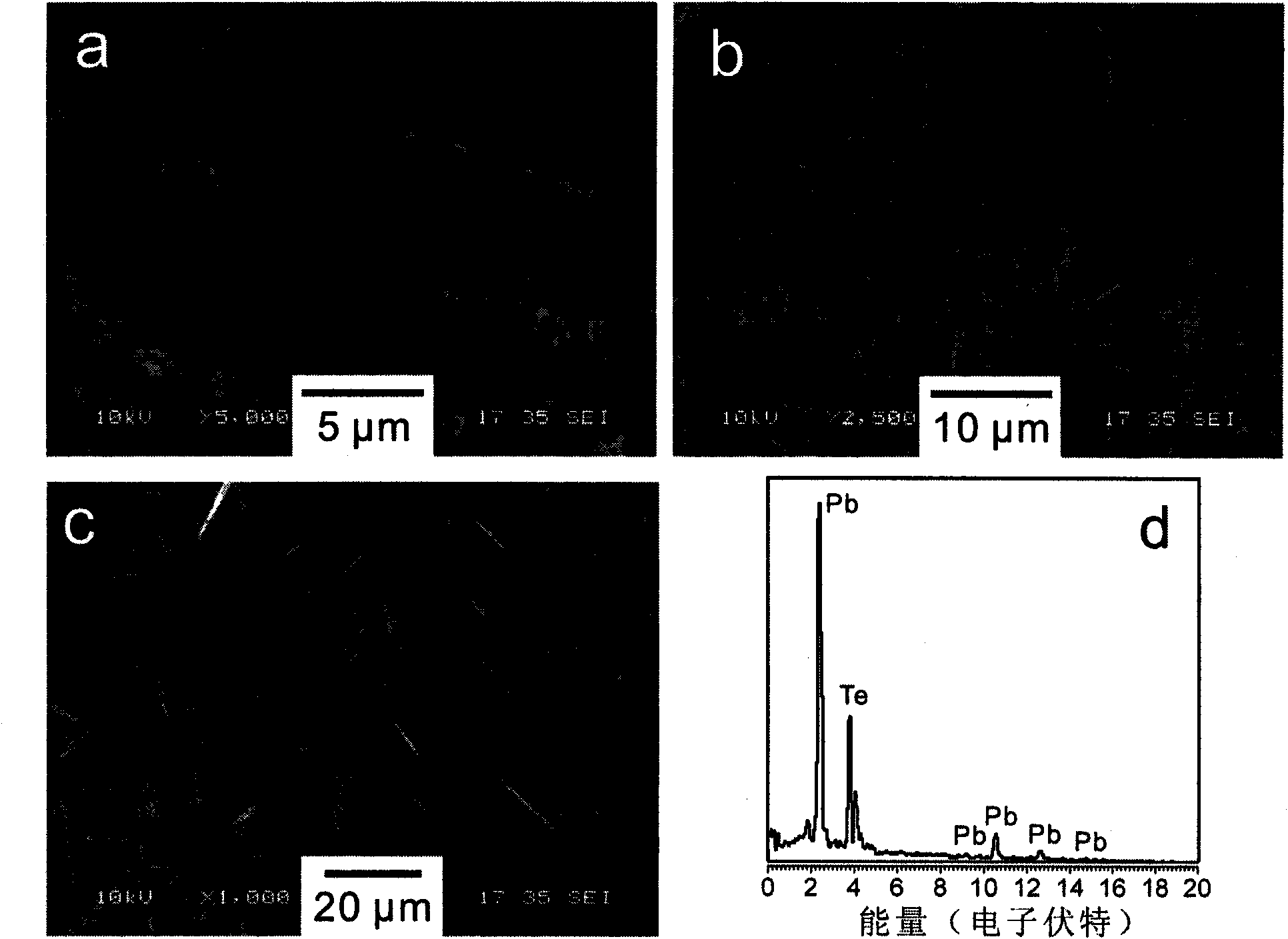

[0039] The resulting product morphology is quite different from Example 1. SEM observations showed that the products were mostly rod-like and flake-like nanocrystals ( figure 2 (b)). Transmission electron microscope observation shows that the product contains aggregates of nanoparticles, and contains a large number of rod-like and sheet-like nanostructures ( image 3 (b)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com