Tundish

A technology of tundish and pouring body, which is applied in the field of tundish, can solve the problems of aggravated refractory material erosion, reduction, and cannot meet the needs of the development of efficient continuous casting technology, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

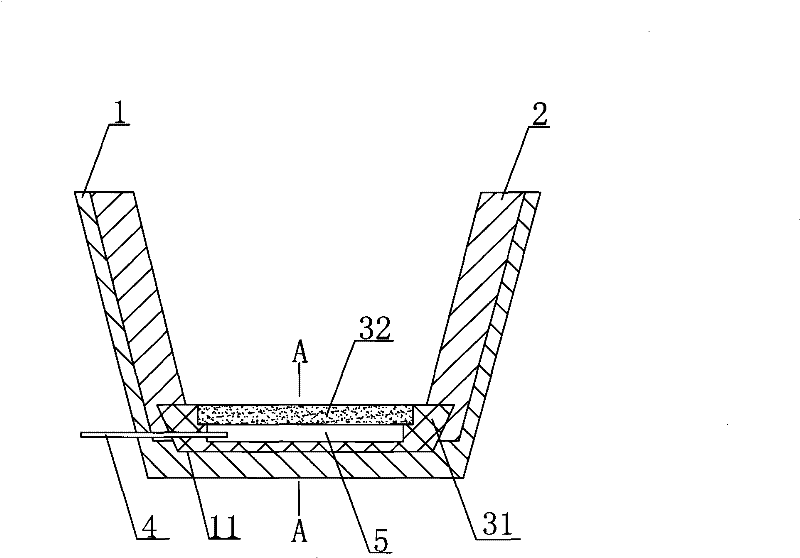

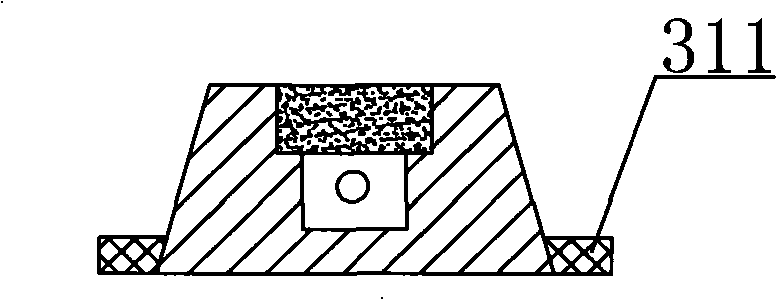

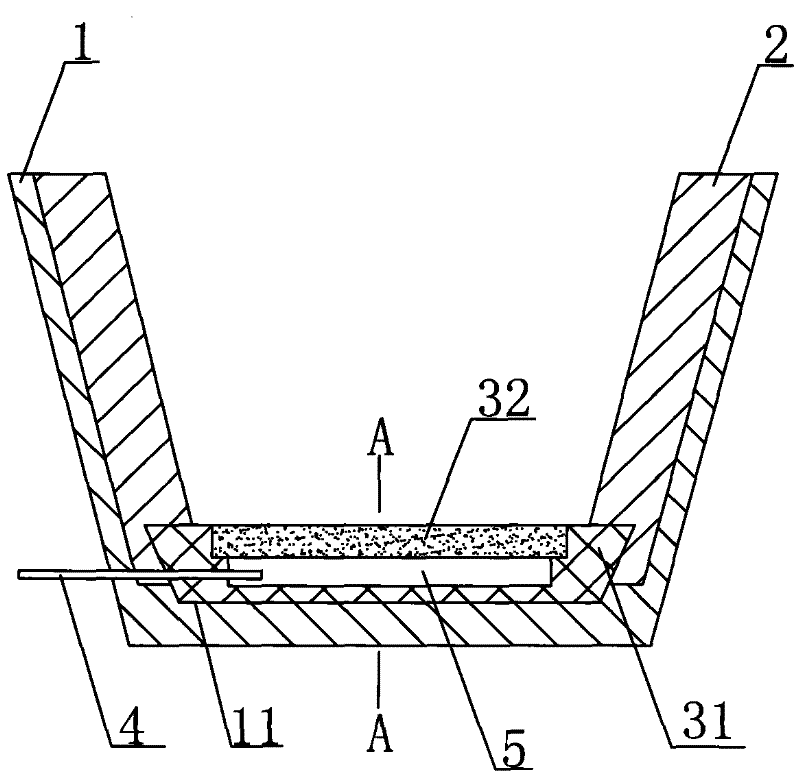

[0014] Such as figure 1 , figure 2 Shown is an embodiment of the present invention, a tundish comprising a permanent layer 1 and a working layer 2 arranged on the inner surface of the permanent layer 1, an air curtain retaining wall is provided on the bottom of the permanent layer 1, the The air curtain retaining wall includes a pouring body 31 and a ventilating plate 32 fixed on the pouring body 31, an air chamber 5 is formed between the pouring body 31 and the ventilating plate 32, and the air chamber 5 communicates with the outside world through the vent pipe 4, The pouring body 31 is connected to the air-permeable plate 32 by pouring. The pouring connection is simple and convenient, relatively firm, and has good sealing performance, which prevents energy waste caused by gas leakage. The pouring body 31 is provided with a boss 311 for fixedly connecting the permanent layer 1, and the boss 311 is arranged on both sides of the casting body 31, and is provided with a boss fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com