Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

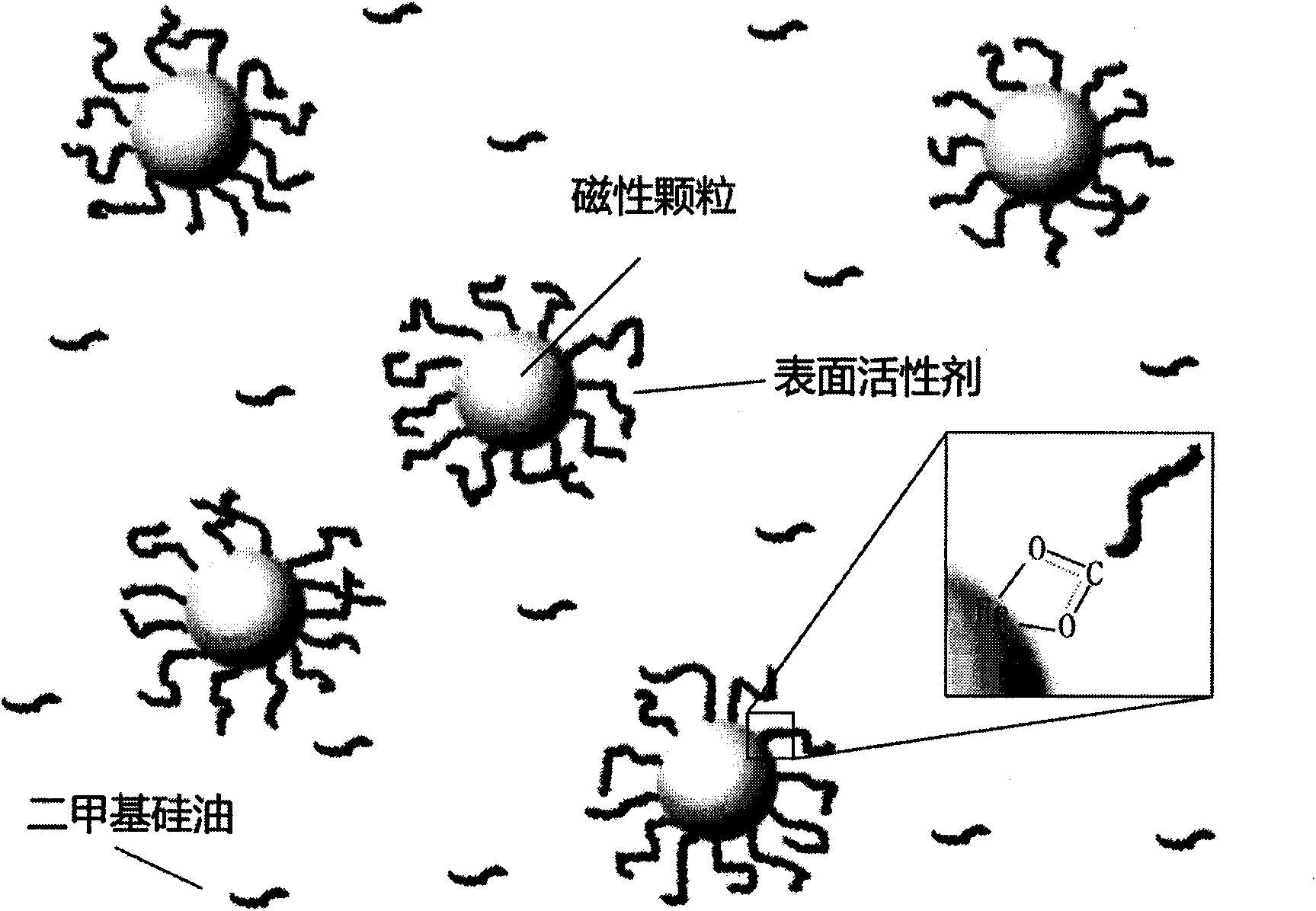

A technology that is resistant to oxidation of dimethyl silicone oil and dimethyl silicone oil, which is applied in the field of nanoscience and can solve problems such as affecting the stability and service life of magnetic liquids, the low coverage rate of modifiers on the particle surface, and reducing the solubility of modified particles, etc. problems, to achieve the effects of excellent thermal stability and oxidation resistance, high chemical adsorption modification efficiency, and low viscosity-temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

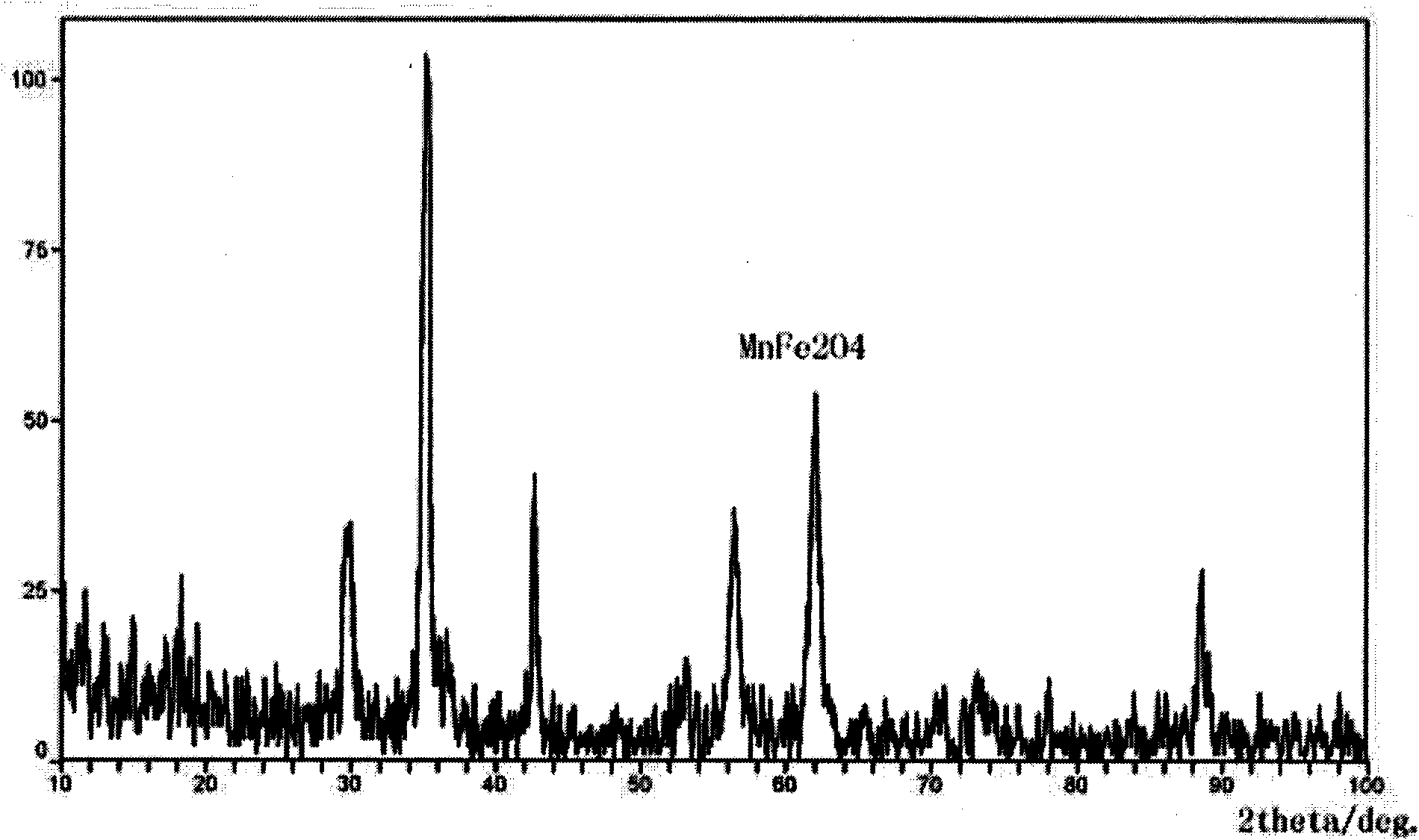

[0040] Example 1 Preparation of MnFe 2 o 4 Dimethicone based magnetic fluid

[0041] (1) Preparation of nano-MFe 2 o 4 Magnetic particles: prepare 40mL Mn 2+ , Fe 3+ DEG mixed solution in a beaker, where Mn 2+ The concentration is 0.75mol / L, Fe 3+ The concentration is 1.0mol / L. Prepare 60 mL of NaOH solution with a concentration of 3.0 mol / L in a 250 mL round bottom flask, fill it with argon, and raise the temperature to 220 °C. Keep the stirring rate at 300r / min, add the DEG solution containing metal ions into the NaOH solution, heat and boil for 10 minutes to prepare nano-MnFe 2 o 4 Magnetic particles; the resulting nano-MnFe 2 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the eluate is σ=92μs / cm;

[0042] (2) Nano-MFe 2 o 4 Activation treatment of magnetic particles: the nanometer MnFe that step (1) obtains 2 o 4 Add 30ml of FeCl with a concentration of 1.0mol / L to the magnetic particles 3 solution, heated a...

Embodiment 2

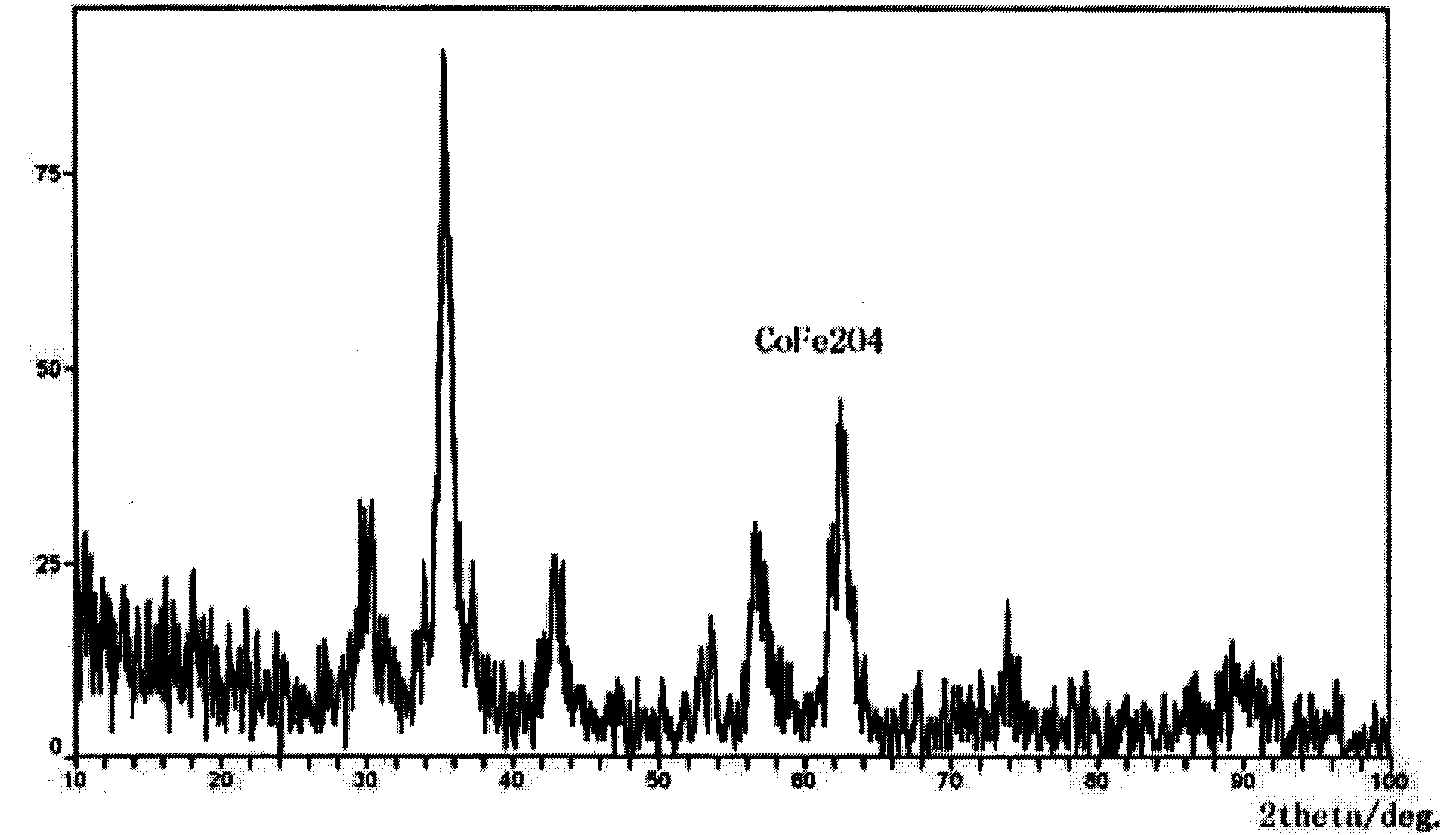

[0049] Example 2 Preparation of CoFe 2 o 4 Dimethicone based magnetic fluid

[0050] (1) Preparation of nano-MFe 2 o 4 Magnetic particles: prepare 40mL Co 2+ , Fe 3+ DEG mixed solution in 80mL beaker, where Co 2+ The concentration is 0.75mol / L, Fe 3+ The concentration is 1.0mol / L. Prepare 60 mL of NaOH solution with a concentration of 3.0 mol / L in a 250 mL round bottom flask, fill it with argon, raise the temperature to 220 °C, keep the stirring speed at 300 r / min, add the DEG solution containing metal ions into the NaOH solution, Nano-CoFe can be prepared by heating and boiling for 10 minutes 2 o 4 Magnetic particles; the resulting nano-CoFe 2 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the eluate is σ=87μs / cm;

[0051] (2) Nano-MFe 2 o 4 Activation treatment of magnetic particles: the nano-CoFe obtained in step (1) 2 o 4 Add 30ml of FeCl with a concentration of 1.0mol / L to the magnetic particles 3 solution,...

Embodiment 3

[0056] Example 3 Preparation of NiFe 2 o 4 Dimethicone based magnetic fluid

[0057] (1) Preparation of nano-MFe 2 o 4 Magnetic particles: prepare 40mL Ni 2+ , Fe 3+ DEG mixed solution in a beaker, where Ni 2+ The concentration is 0.75mol / L, Fe 3+ The concentration is 1.0mol / L. Prepare 60 mL of NaOH solution with a concentration of 3.0 mol / L in a 250 mL round bottom flask, fill it with argon, and raise the temperature to 220 °C. Keep the stirring rate at 300r / min, add the DEG solution containing metal ions into the NaOH solution, heat and boil for 10 minutes to prepare nano-NiFe 2 o 4 Magnetic particles; the resulting nano-NiFe 2 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the eluate is σ=90μs / cm;

[0058] (2) Nano-MFe 2 o 4 Activation treatment of magnetic particles: the nano-NiFe obtained in step (1) 2 o 4 Add 30ml of FeCl with a concentration of 1.0mol / L to the magnetic particles 3 solution, heated and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com