High precision hollow prism reflector

A technology of hollow prisms and reflectors, which is applied in the field of optical instruments and can solve problems such as heavy use of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

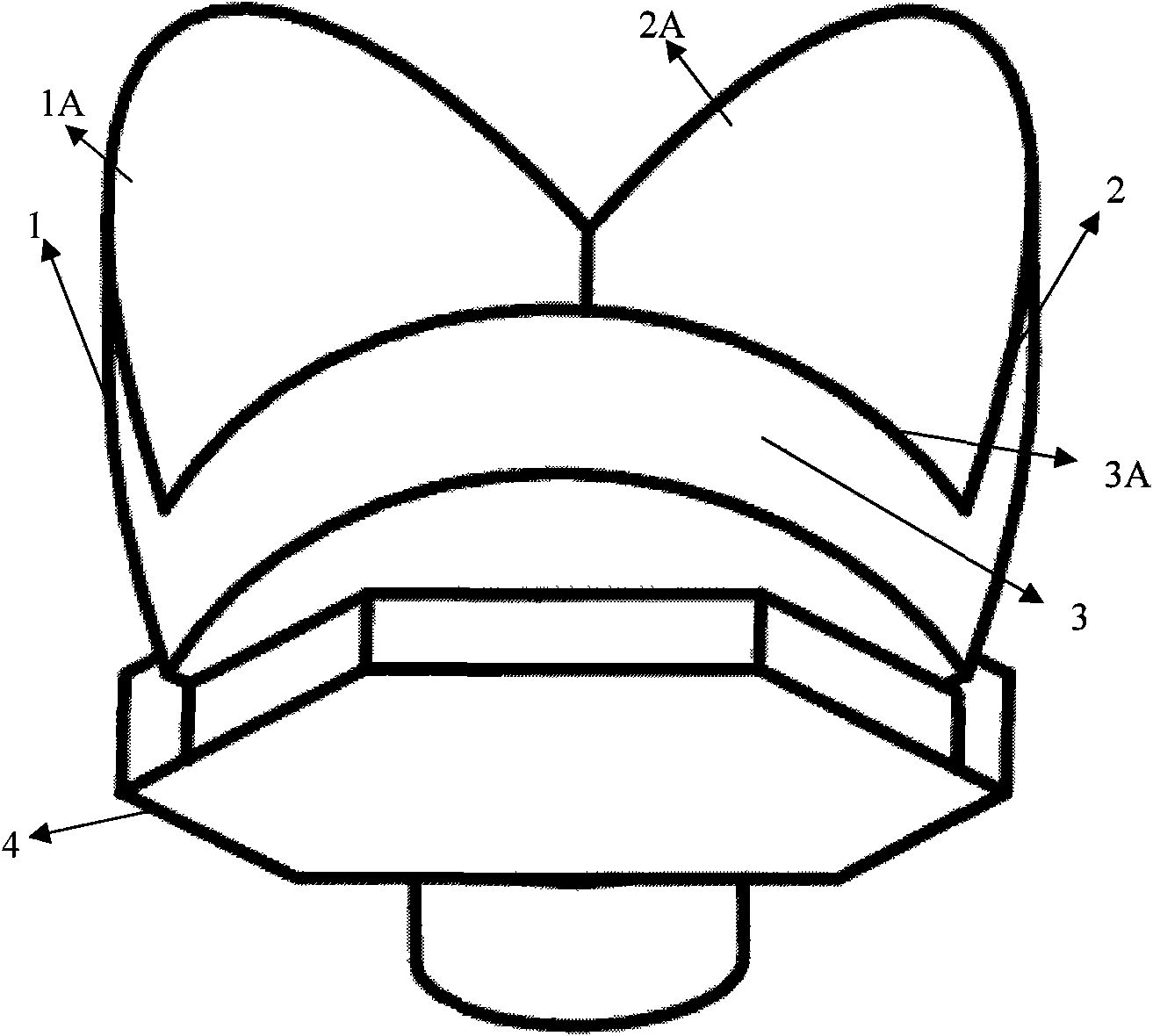

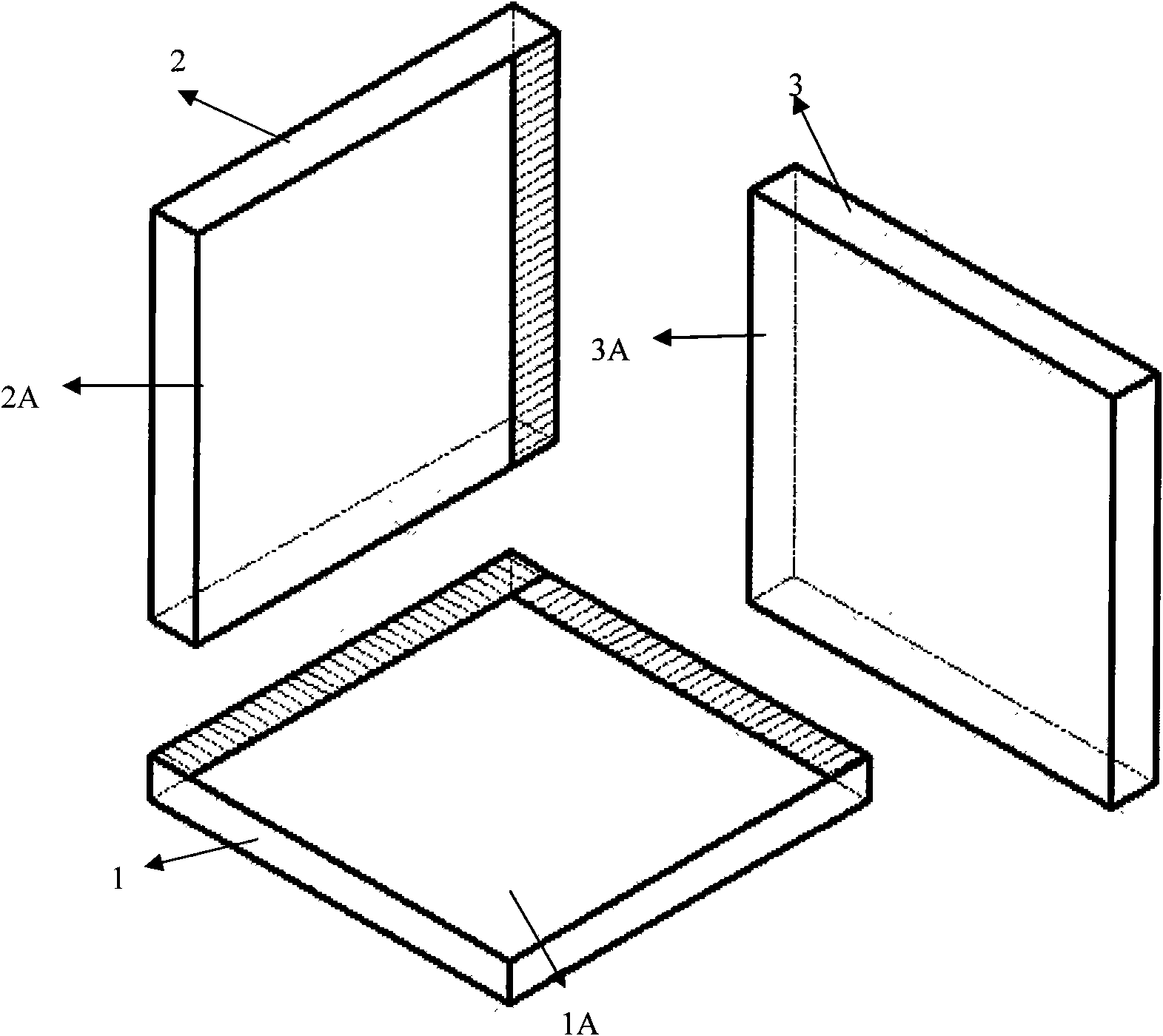

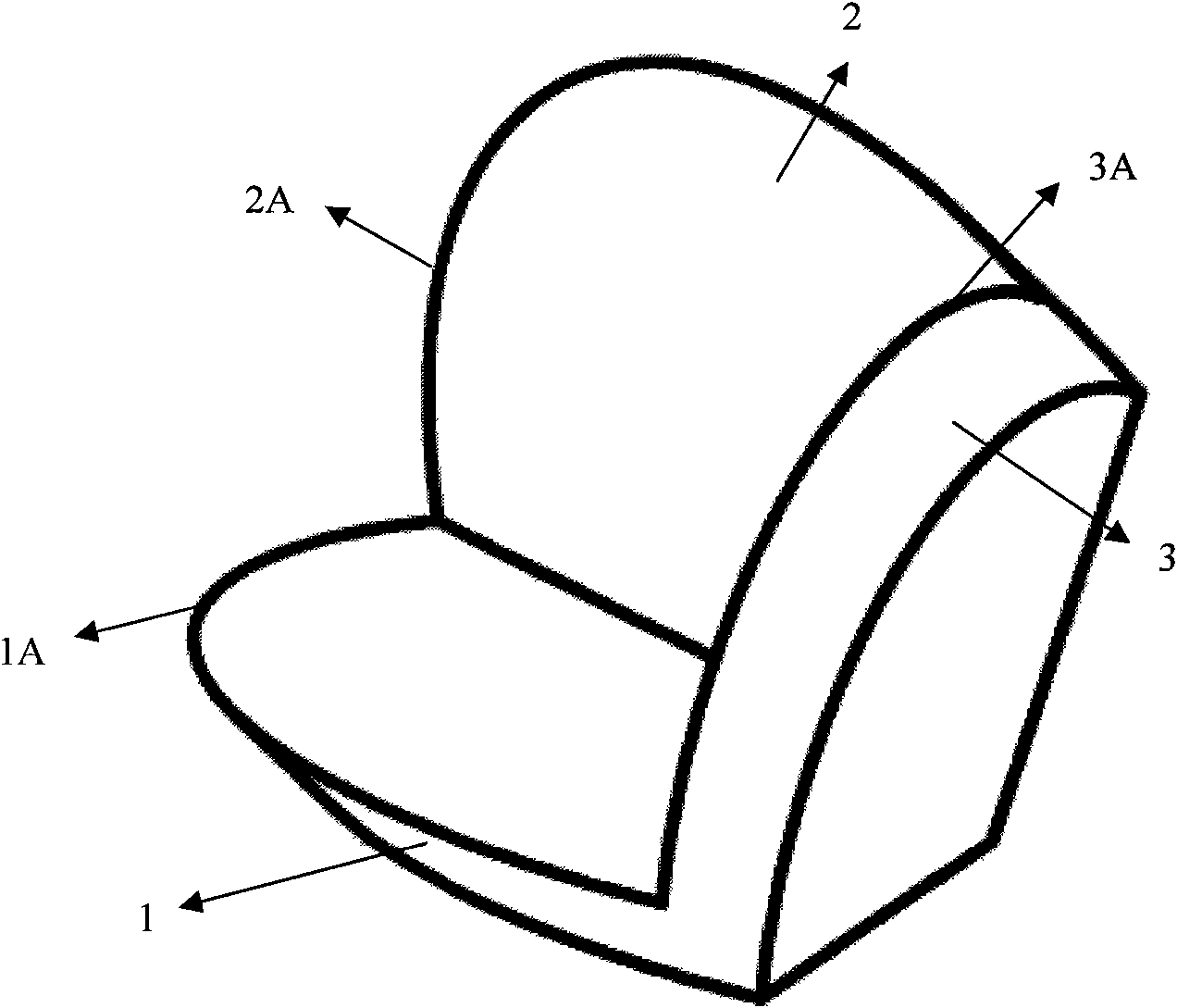

[0026] A high-precision hollow prism reflector device includes first, second and third glass plates 1, 2 and 3, inner surfaces 1A, 2A and 3A of the first, second and third glass plates, and a prism support 4. The connection relationship is: the first, second, and third glass plates 1, 2, and 3 are bonded to each other, and the adhesive (photosensitive adhesive) can easily connect the first, second, and third glass plates 1, 2 to each other. , 3 Bonding into a hollow prism reflector. The first glass plate 1 and the second glass plate 2 are bonded by photosensitive adhesive, and the third glass plate 3 is bonded with the first glass plate 1 and the second glass plate 2 by photosensitive adhesive (the name of the photosensitive adhesive material is GBN-501), After bonding, irradiate with purple light to cure the photosensitive adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com