Steam temperature control method for boiler with big load variable rate and dedicated device thereof

A rate of change, steam temperature control technology, applied to controllers with specific characteristics, using electric mode for temperature control, control systems, etc., can solve problems such as boiler steam temperature disturbance, solve secondary overtemperature, improve average Response speed, the effect of overcoming large inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

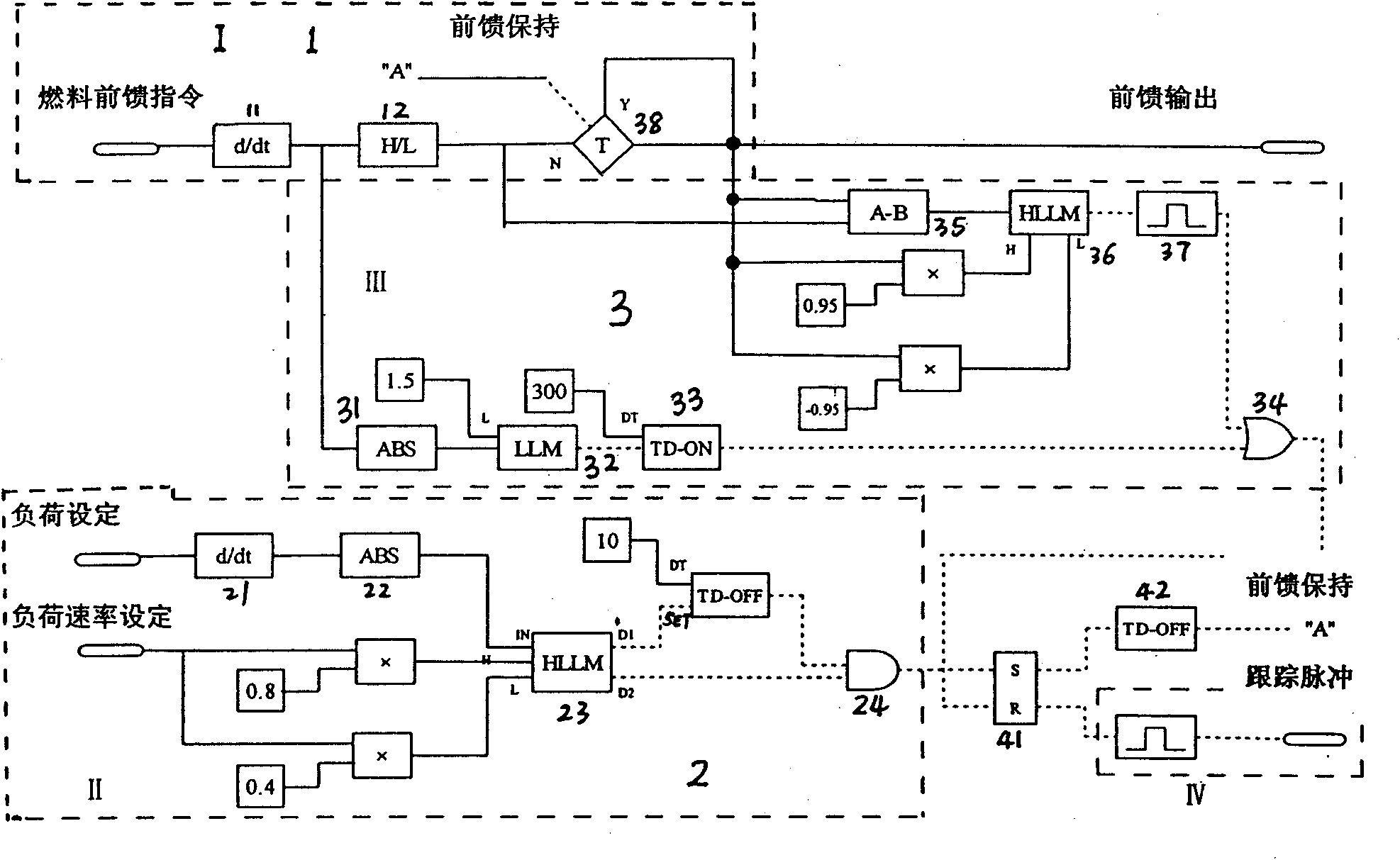

[0033] see image 3 , the special-purpose device that the present embodiment adopts is formed by connection of differential module 1, state judgment and setting module 2, reset module 3 and reset holding and tracking module 4;

[0034] 1) The differential module 1 includes a feedforward differential circuit 11 and a high-low limiter circuit 12, the output end of the feedforward differential circuit 11 is connected to the input end of the reset module 3 through the high-low limiter circuit 12; the input terminal of the feedforward differential circuit 11 is connected with fuel Feedforward command output;

[0035]2) The state judgment and setting module 2 includes a load differential circuit 21, a load absolute value circuit 22, one of the rate multipliers, the second of the rate multipliers, a rate alarm 23, one of the delay breaking circuits and an AND gate circuit 24 ; One of the rate multipliers and two of the rate multipliers each have an input terminal connected to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com