Self-cleaning iron ion removing separation device

A separation device and iron ion technology, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of non-continuous production, not easy to loosen the bed, increase labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

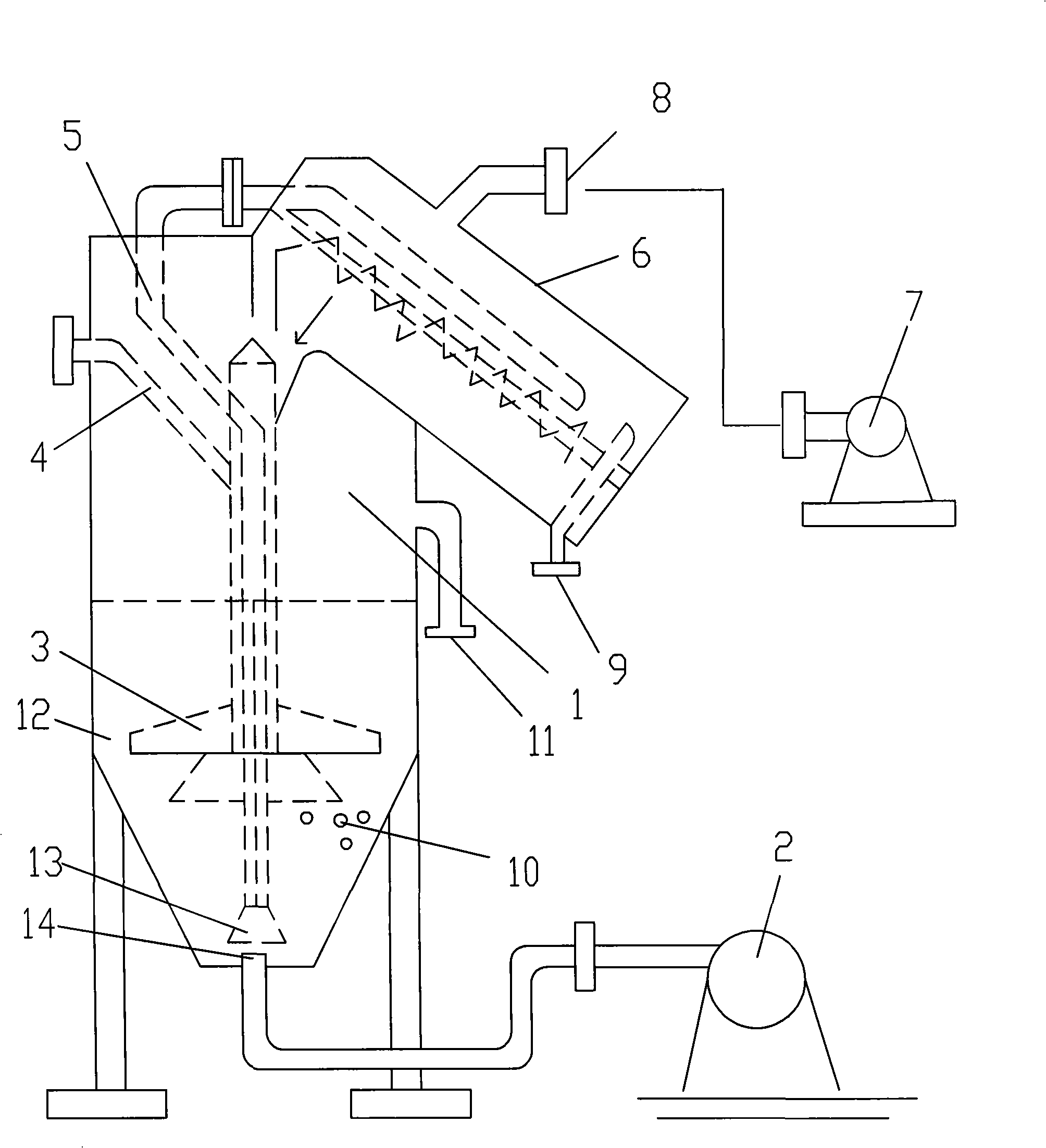

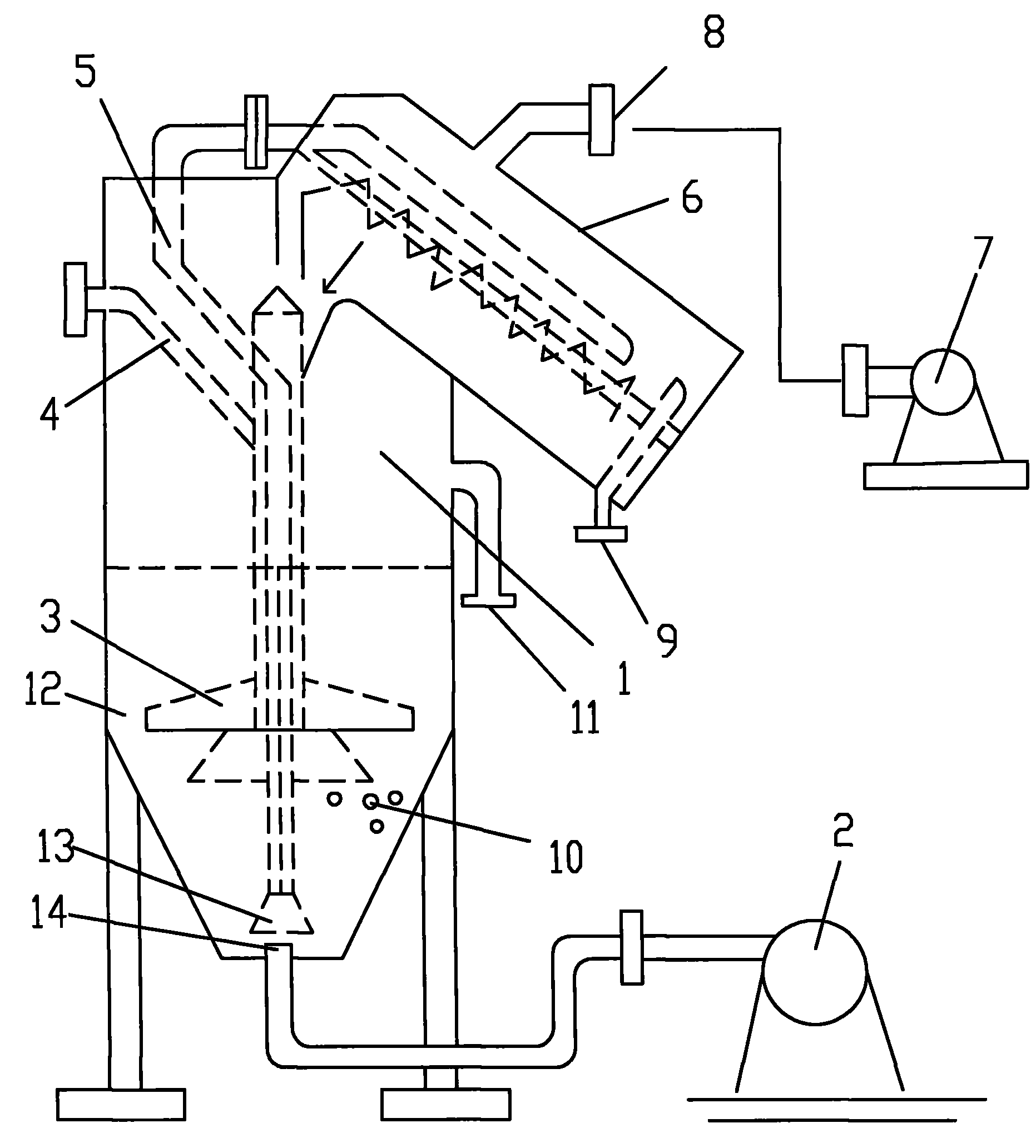

[0013] As shown in the figure: the lower part of the barrel 1 is a filter bed 12 for placing the mixture of manganese sand and B metal, a water distribution cover 3 is arranged in the filter bed 12, and a water supply pipe 4 is arranged on the upper part of the barrel 1, so The water supply pipe 4 is connected with the water distribution cover 3; there is a water outlet pipe 5 in the barrel body 1, the lower end of the water outlet sand pipe 5 is located at the bottom of the barrel body 1, and the upper end of the water outlet sand pipe 5 is located. It is connected with the auger 6 located at the upper part of the barrel 1; the compressed air outlet 14 is arranged at the bottom of the barrel 1 facing the water outlet sand pipe 5, and the clean water is arranged on the wall of the barrel 1 corresponding to the top of the filter bed 12 Exit 11.

[0014] The auger 6 is inclined and arranged, there is a rotating shaft in the auger 6, and there are spiral continuous blades on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com