Boring and milling head

A milling head, boring and milling technology, which is applied in the field of boring and milling machines, can solve problems such as the difficulty in processing structural shape parts, and achieve the effects of improving processing efficiency, reducing production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

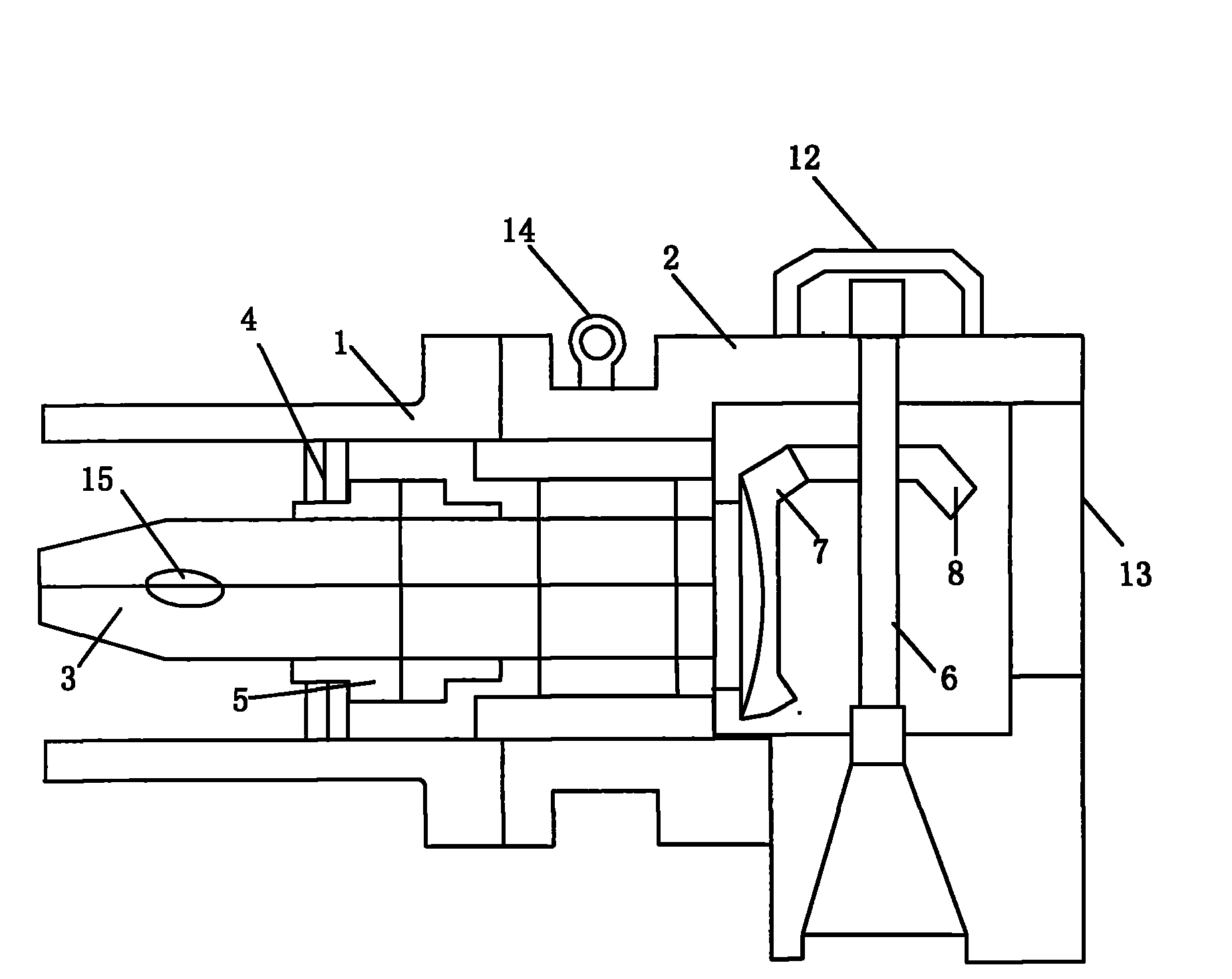

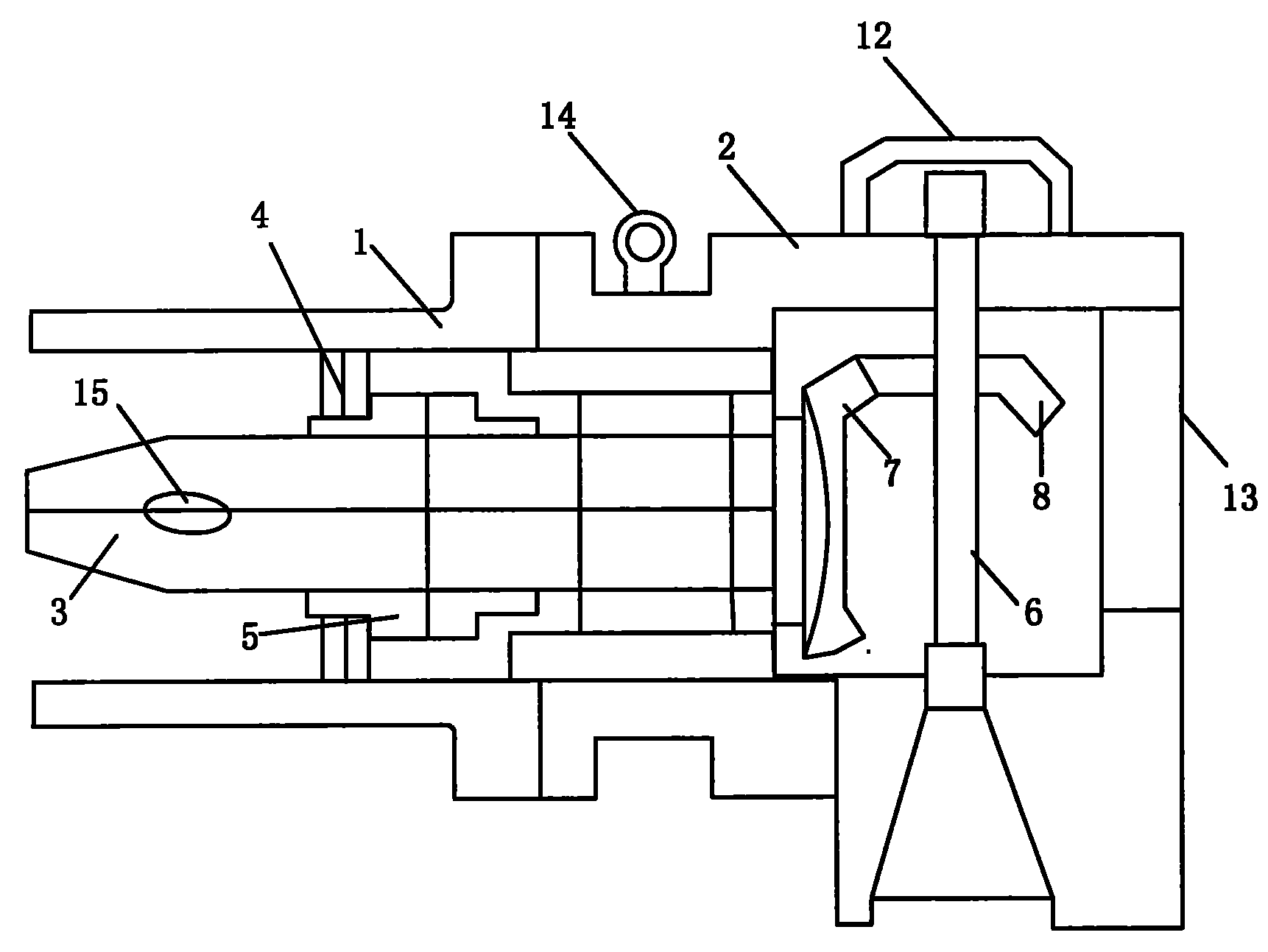

[0020] like figure 1 As shown, the body 2 is provided with a lifting ring 14 capable of bearing load and a machine cover 13 for easy maintenance, the base 1 is movably connected with the body 2, the main shaft 3 is fixed in the base 1 and the body 2 through the bearing 4 and the tooth crown 5, the main shaft 3 is provided with locking hole 15, and one end of main shaft 3 links to each other with power source motor, and the other end of main shaft 3 links to each other with bevel tooth 17; The bevel teeth II 8 are connected, and the bevel teeth I 7 are meshed with the bevel teeth II 8; one end of the milling head spindle 6 is provided with a back cap 12 to prevent the milling head spindle from moving axially.

Embodiment 2

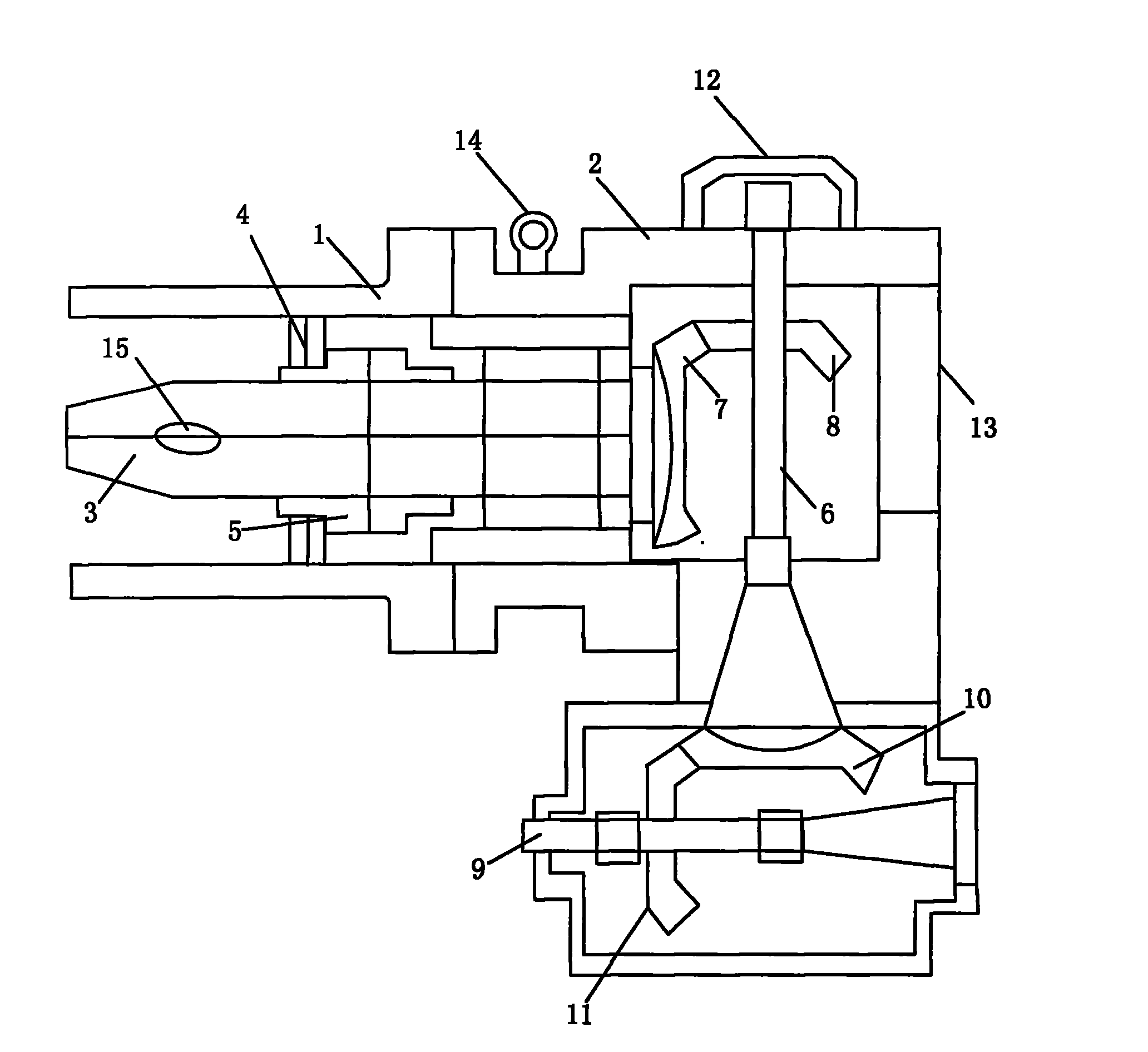

[0022] like figure 2 As shown, the body 2 is provided with a lifting ring 14 capable of bearing load and a machine cover 13 for easy maintenance, the base 1 is movably connected with the body 2, the main shaft 3 is fixed in the base 1 and the body 2 through the bearing 4 and the tooth crown 5, the main shaft 3 is provided with locking hole 15, and one end of main shaft 3 links to each other with power source motor, and the other end of main shaft 3 links to each other with bevel tooth 17; The bevel teeth II 8 are connected, and the bevel teeth I 7 are meshed with the bevel teeth II 8; one end of the milling head main shaft 6 is perpendicular to the milling head main shaft 6, and a milling head auxiliary shaft 9 is arranged, and the milling head main shaft 6 is connected with the auxiliary bevel gear I 10, The auxiliary shaft 9 of the milling head is connected with the auxiliary bevel gear II 11, and the auxiliary bevel gear I 10 is meshed with the auxiliary bevel gear II 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com