Sandwich type piezoelectric transducer automatic assembly machine

A piezoelectric transducer and assembly machine technology, applied in the field of ultrasonic waves, can solve the problems of easily broken ceramic sheets, increased working time, injuries to operators, etc., and achieve the effects of automatic assembly, safe assembly operation, and high assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

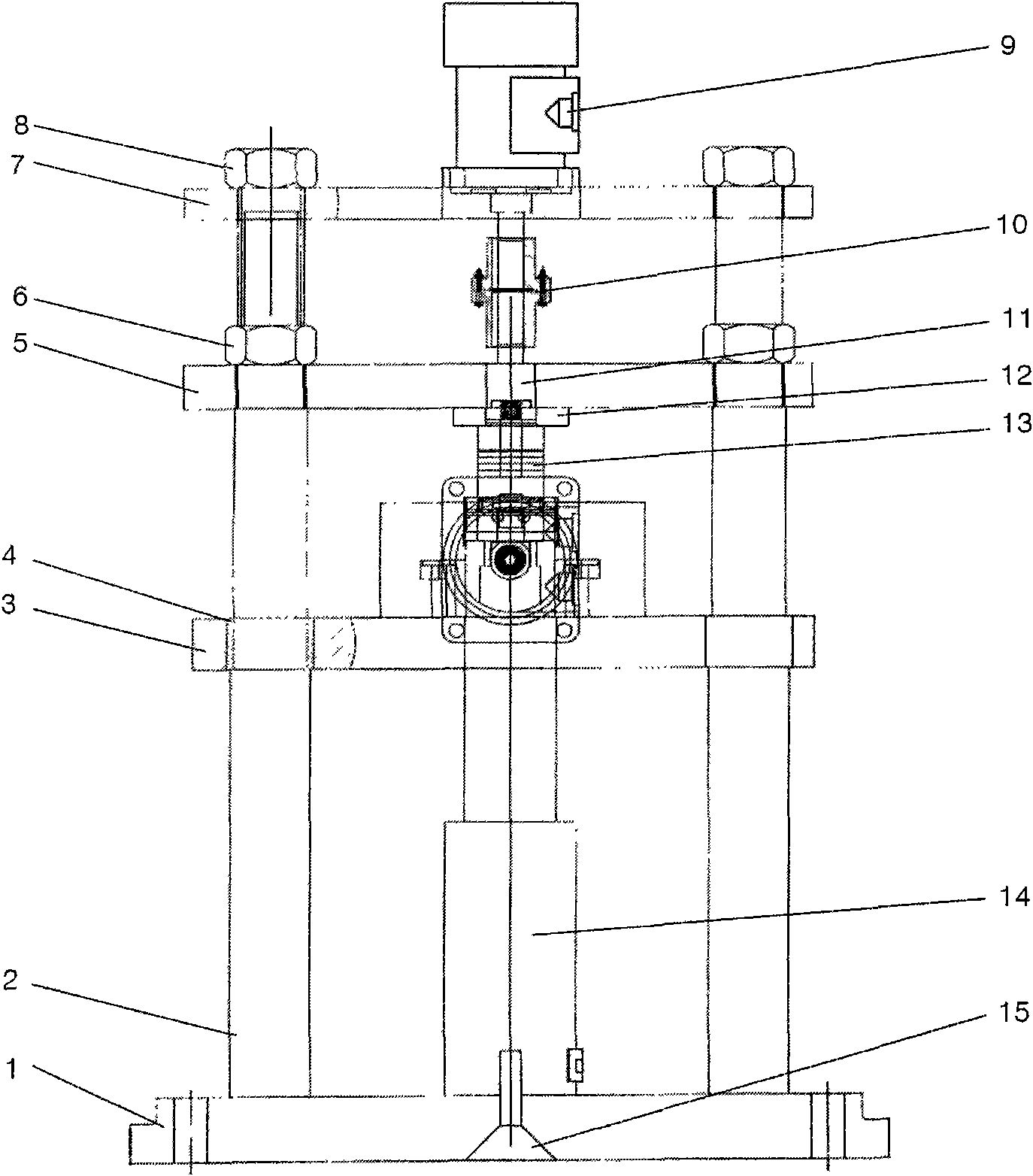

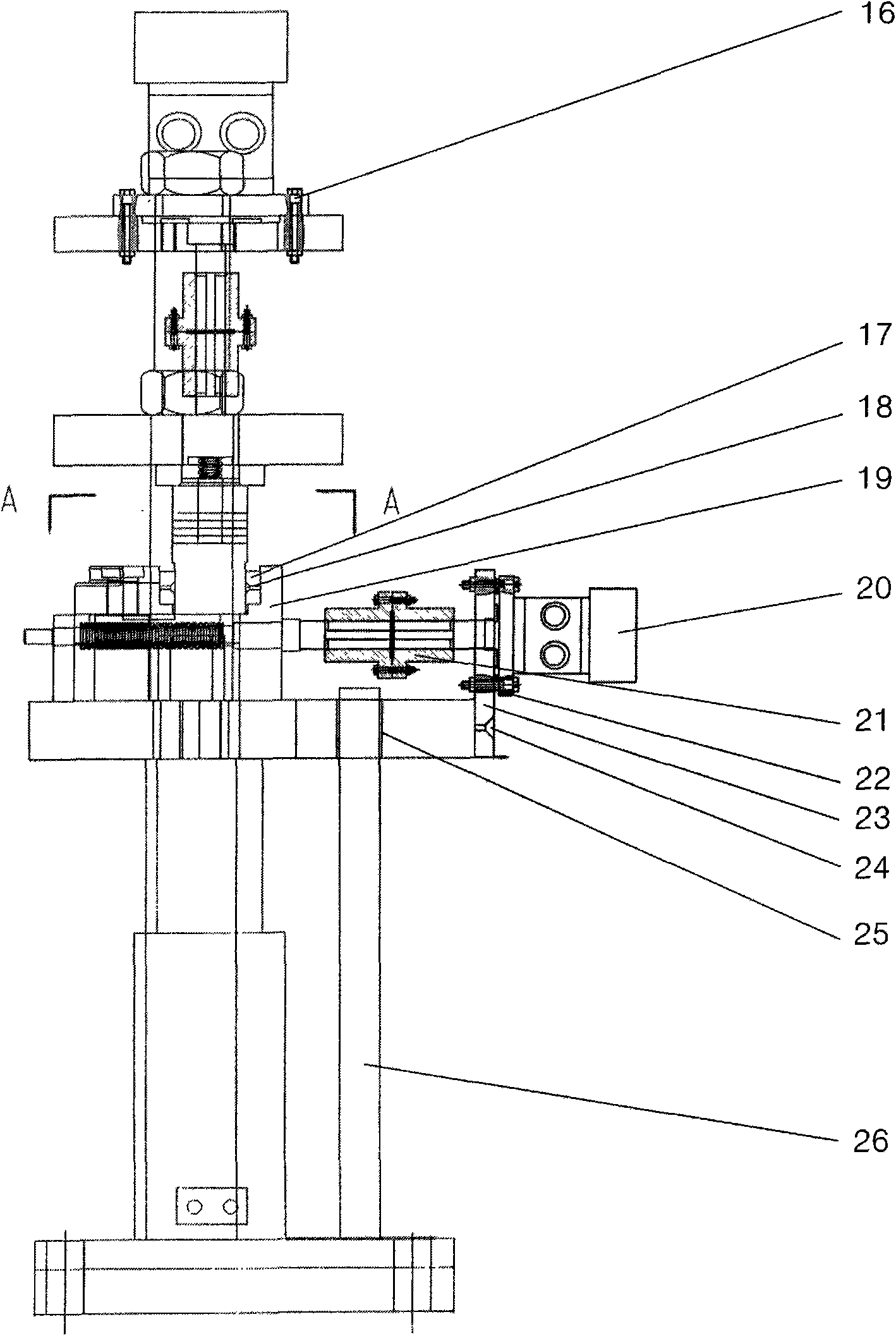

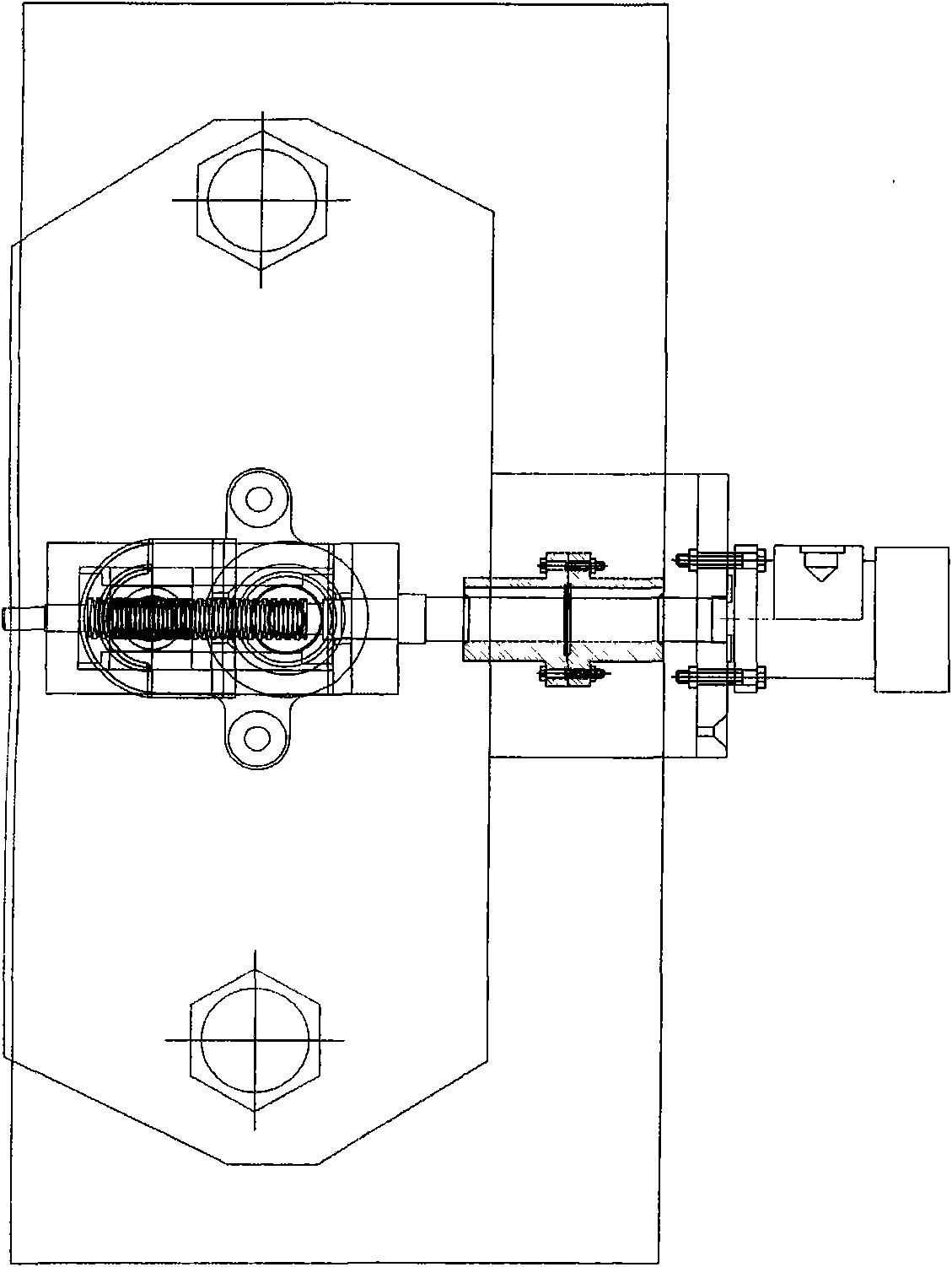

[0027] The sandwich piezoelectric transducer automatic assembly machine includes a base 1, a column 2, a push plate 3, a first copper bush 4, a pressure plate 5, a first nut 6, a support plate 7, a second nut 8, a first hydraulic pressure Motor 9, first coupling 10, special sleeve 11, copper gasket 12, sandwich piezoelectric transducer 13, oil cylinder 14, first screw 15, second screw 16, positioning block 17, third screw 18. Vice 19, second hydraulic motor 20, second coupling 21, fourth screw 22, vertical plate 23, fifth screw 24, second copper bushing 25, guide shaft 26, third nut 27, rear Reflector 28, piezoelectric ceramic sheet 29, electrode 30, front reflector 31, two columns 2 are installed on the base 1 by threads, oil cylinder 14 is fixed on the base 1 by the first screw 15, push plate 3, pressing plate 5. The support plate 7 is set on the two columns 2, wherein the push plate 3 slides axially along the column 2 through the first copper bushing 4, the pressure plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com