Liquid crystal display, active element array substrate and method for manufacturing active element array substrate

An active element and array substrate technology, which is applied in the field of array substrate and its manufacturing method and display device, can solve the problems of impedance rise, resistance-capacitance delay, increase of signal lines, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In the content described below, terms such as "first" and "second" added in front of each material layer are only used to separate different material layers, and do not represent the sequence of process steps or other meanings.

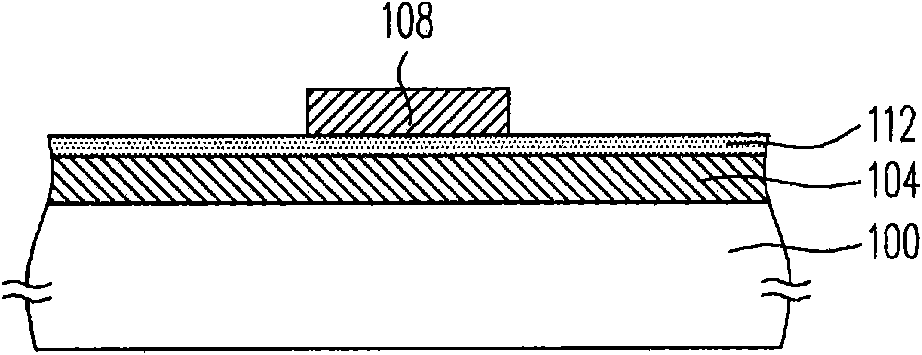

[0067] Figure 2A ~ Figure 2I What is shown is a partial cross-sectional view of the process steps of the active element array substrate according to an embodiment of the present invention, and Figure 3A-3F depicted as Figure 2A ~ Figure 2I Top view of some steps in the process.

[0068] Please refer to Figure 2A and Figure 3A , forming a first patterned conductive layer 210 on an insulating substrate 200 . Figure 2A yes Figure 3A Sectional view along line A-A. In the formation method of the first patterned conductive layer 210, for example, a complete conductive layer is first formed on the insulating substrate 200 by sputtering or other appropriate processes, and then the first photomask process is performed to pattern the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com