Absorbing cavity of infrared gas sensor with wide spectrum light source

A gas sensor and broad-spectrum light source technology, applied in the field of explosion-proof gas detection equipment, can solve the problems of low detection sensitivity and light energy utilization rate, and achieve the effects of improving the absorption effect, reducing the volume, and increasing the beam transmission distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

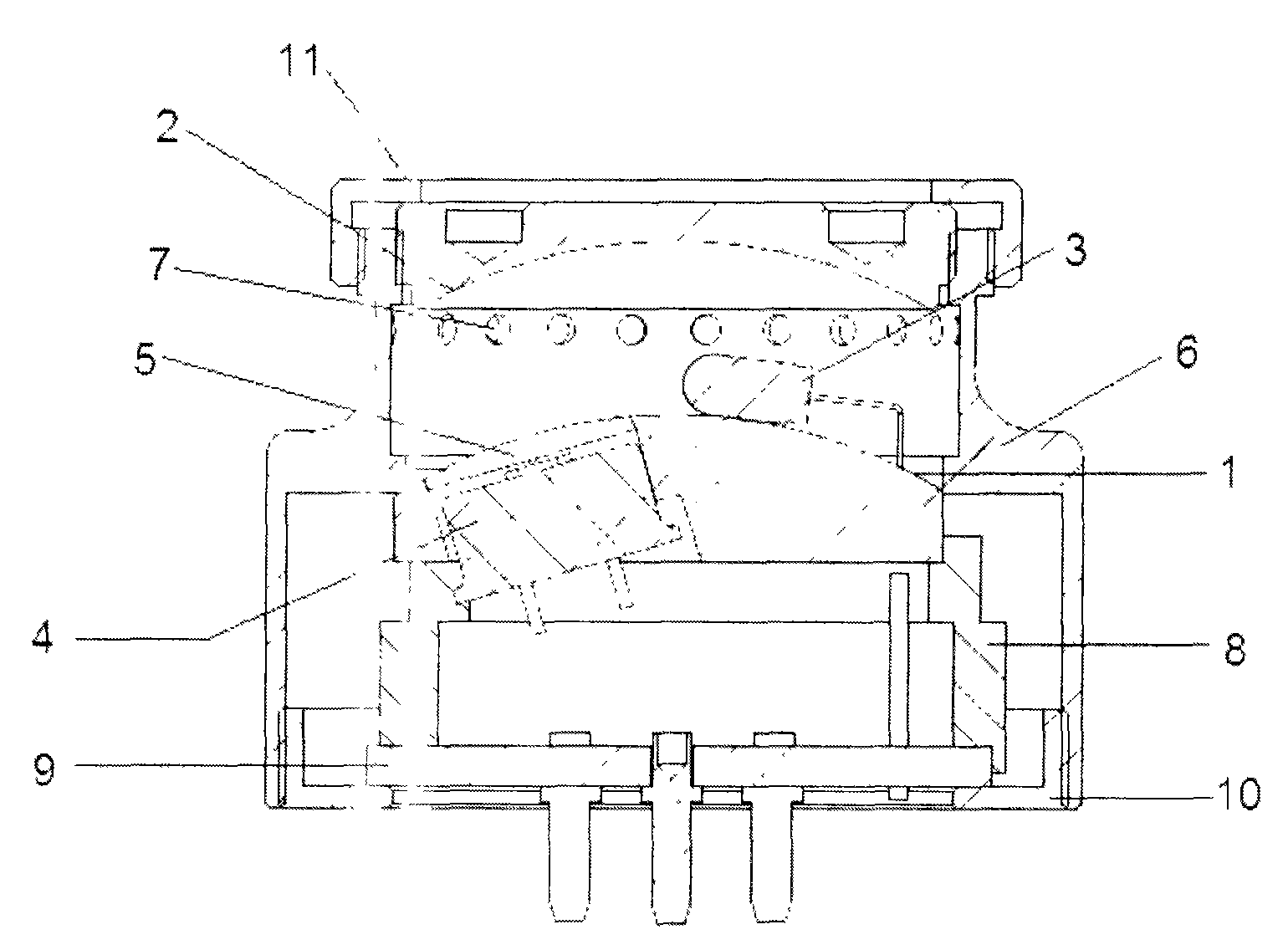

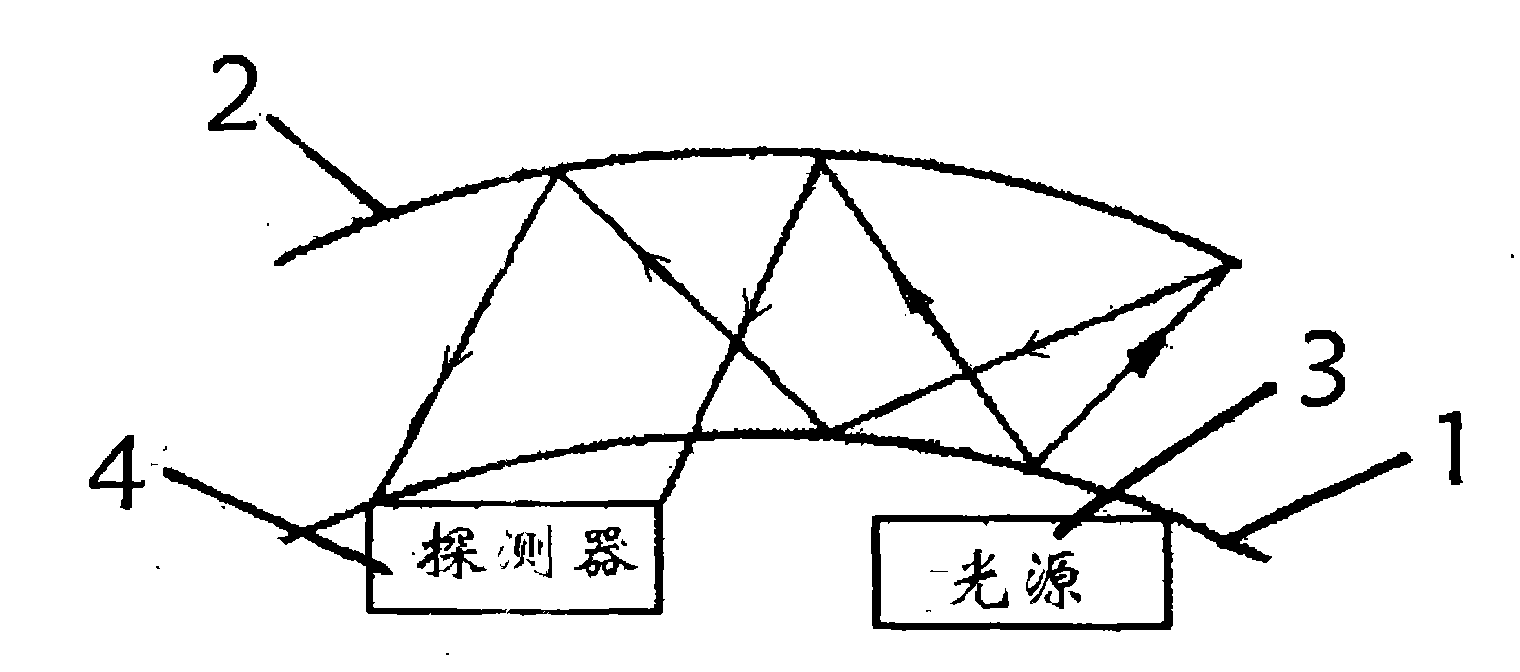

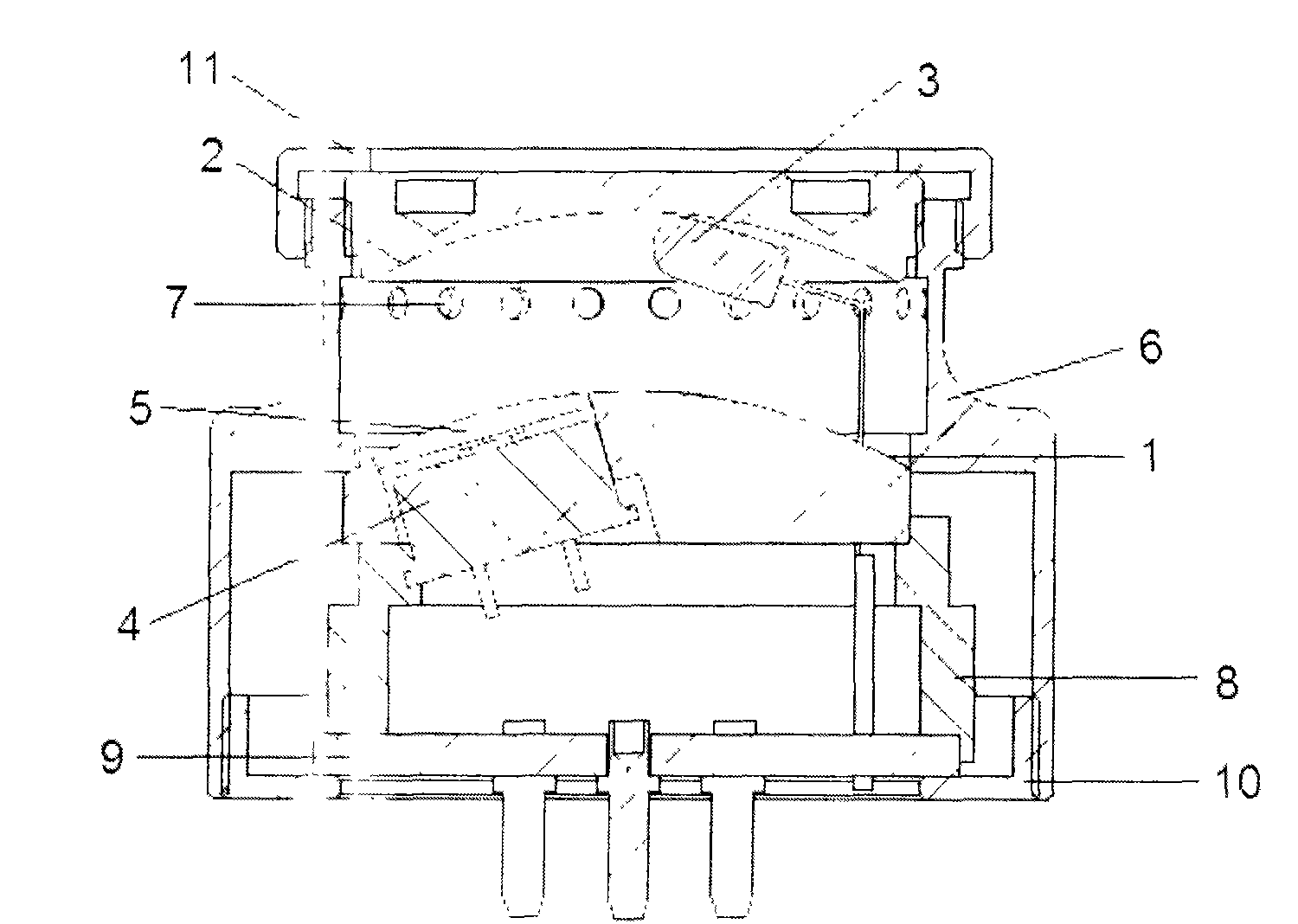

[0019] The invention provides an absorption cavity of a wide-spectrum light source infrared gas sensor. The present invention will be described below in conjunction with the accompanying drawings. exist figure 1 Shown is a schematic diagram of the structure of the sensor in Embodiment 1. The absorption cavity is composed of a downward convex spherical reflector 1 and an upward concave spherical reflector 2. The light source 3 and the infrared detector detector 4 are located on the side of the downward convex spherical reflector 1. The spherical reflector 1, the light source 3 and the infrared detector 4 are fixed on the support 8, the support 8 is fixed on the base 10, and the concave spherical reflector 2 is fixed on the sensor housing 6 top to form a quasi-optical resonant cavity. Therefore, from the light source 3 The emitted light beam is reflected back and forth between the upper concave spherical reflector 2 and the lower convex spherical reflector 1. After the light be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com