Drive-driven-unit with coupling/brake combination

A technology of combination device and output components, applied in the combination of coupling and brake, axial brake, brake type and other directions, can solve the problems of crash and damage of machine parts, achieve no waste of structure space, simple and compact space utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

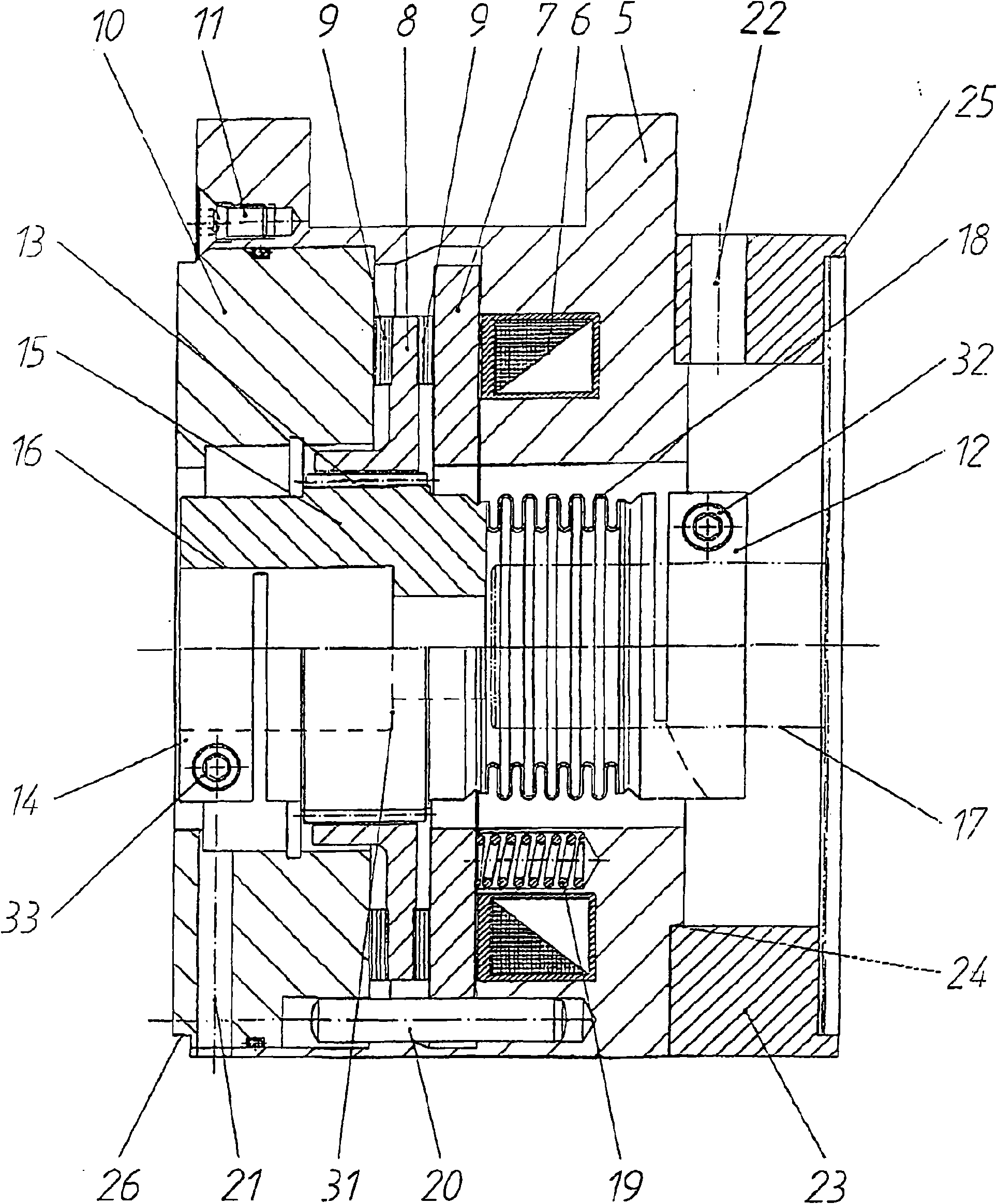

[0029] figure 2 Represents a preferred embodiment of the coupling brake assembly of the present invention, its main feature is that an electrostatic current operated friction brake is built into the "spacer" (= figure 1 In the connecting piece 3), the associated brake rotor 8 is mounted on the meshing teeth 13 on the central hub 15 of the hollow shaft 16 on the output side in the spacer. The shaft head connection not shown in detail on the side.

[0030] The hollow shaft 16 on the output side has an axial extension facing the drive side, which is designed as a flexible coupling, which is designed in particular as a welded bellows coupling with an end lock on the drive side. ring 12, wherein the locking ring 12 can be operated with a clamping screw 32.

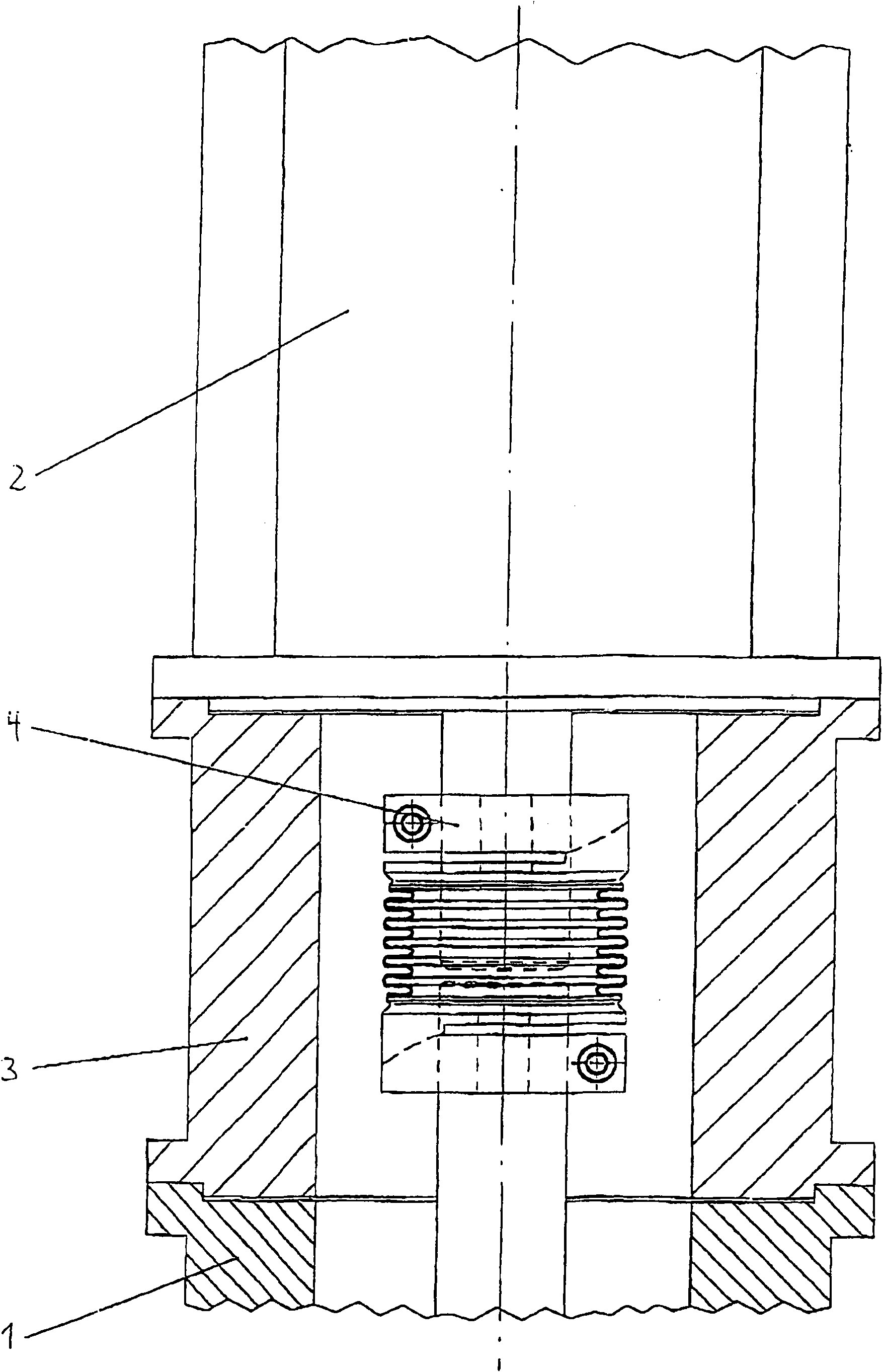

[0031] exist figure 2 The hollow shaft 16 completely surrounding the output side and the bellows coupling 18 on the drive side are equivalent to figure 1 The outer housing of the connecting piece 3 or the spacer is also d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com