Reinforcement method for fibre-quartz ceramic-base composite material

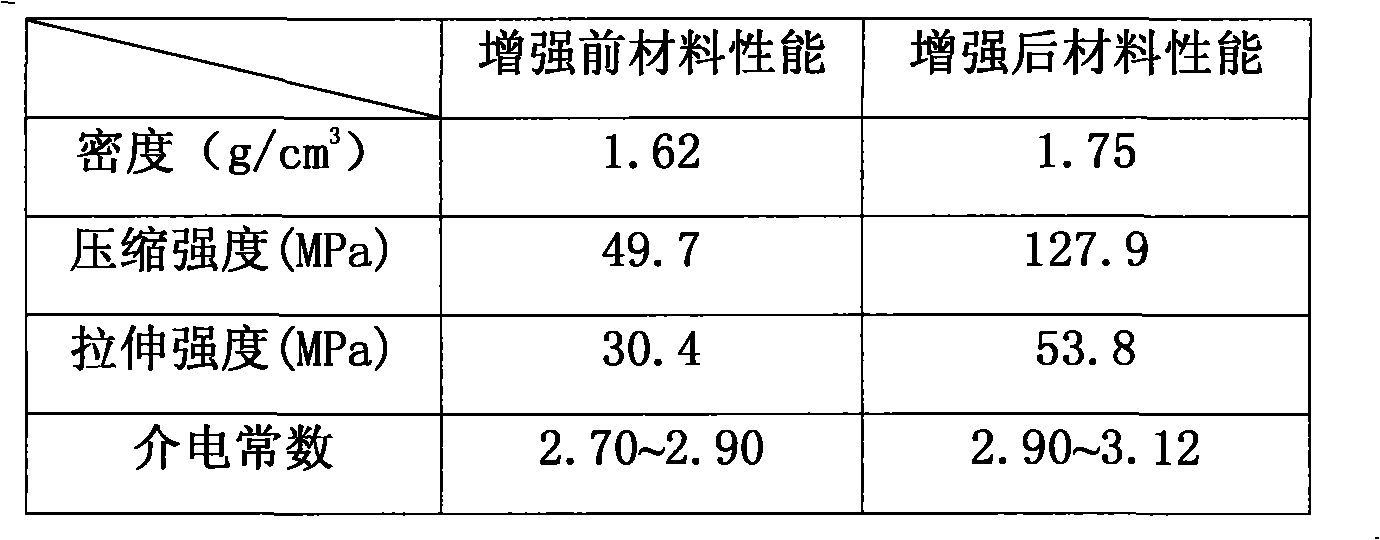

A technology of composite materials and quartz ceramics, which is applied in the reinforcement of fiber-quartz ceramic matrix composite materials and the field of wave-transmitting materials, can solve the problems of poor mechanical properties and limited applications of fiber-quartz ceramic matrix composite materials, and meet requirements and improve Density uniformity, effect of enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First prepare the sol slurry, the preparation method is as follows: fully mix 2mol absolute ethanol, 1mol acetylacetone and 1mol tetraethyl orthosilicate, then use hydrochloric acid to adjust the pH value of distilled water to 2.5, and slowly add it to the mixed solution, fully After stirring, it was sonicated in an ultrasonic wave for 30min.

[0030] The fiber fabric is immersed in the quartz slurry, and it is formed by liquid phase infiltration-in-situ solidification to prepare a composite material green body, and then the green body is immersed in the sol slurry prepared by the above method, and vacuum impregnated (vacuum pressure is 0.01MPa) , make the green body infiltrate the sol slurry, then gel at 70°C, heat treatment at 350°C, and get the product in 2 hours.

Embodiment 2

[0032] First prepare the sol slurry: fully mix 5mol absolute ethanol, 2mol glycerin and 3mol tetraethyl orthosilicate, then use nitric acid to adjust the pH value of distilled water to 2.2, and slowly add it to the mixed solution, stir it fully in the ultrasonic wave Sonicate for 30 min.

[0033] The fiber fabric is immersed in the quartz slurry, and then the fiber-reinforced composite body prepared by liquid phase infiltration-in-situ solidification is immersed in the above-mentioned sol-reinforced slurry, and vacuum impregnated (vacuum pressure is 0.008MPa), so that The composite body is infiltrated with sol slurry, then gelled at 75°C, and heat-treated at 400°C for 2 hours to obtain the product.

Embodiment 3

[0035] The reinforcement method of the fiber-quartz ceramic matrix composite material of the present invention, the fiber-quartz ceramic matrix composite material is subjected to sol-enhanced infiltration treatment, and the finished composite material is prepared through gelation and solidification, wherein the mole percentage of the ingredients of the sol slurry is composed of :

[0036] Analytical grade absolute ethanol 30%

[0037] Analytical grade ethyl orthosilicate 10%

[0038] Distilled water 45%

[0039] Acetylacetone 15%.

[0040] Thoroughly mix absolute ethanol, glycerin or acetylacetone and ethyl orthosilicate, then use hydrochloric acid or nitric acid to adjust the pH value of distilled water to 2.5, and slowly add to the mixture, stir well and ultrasonically mix in ultrasonic for 18 minutes for later use.

[0041] Immerse the fiber-quartz ceramic matrix composite body in the above sol-reinforced slurry, vacuum impregnate (vacuum pressure is 0.009MPa), make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com