High glaze cast-coated photographic paper for ink-jet printing

An inkjet printing, high gloss technology, applied in printing, copying/marking methods, etc., can solve the problems of poor adaptability of pigment ink, high production cost, complex process, etc., and achieve reliable printing performance, low production cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

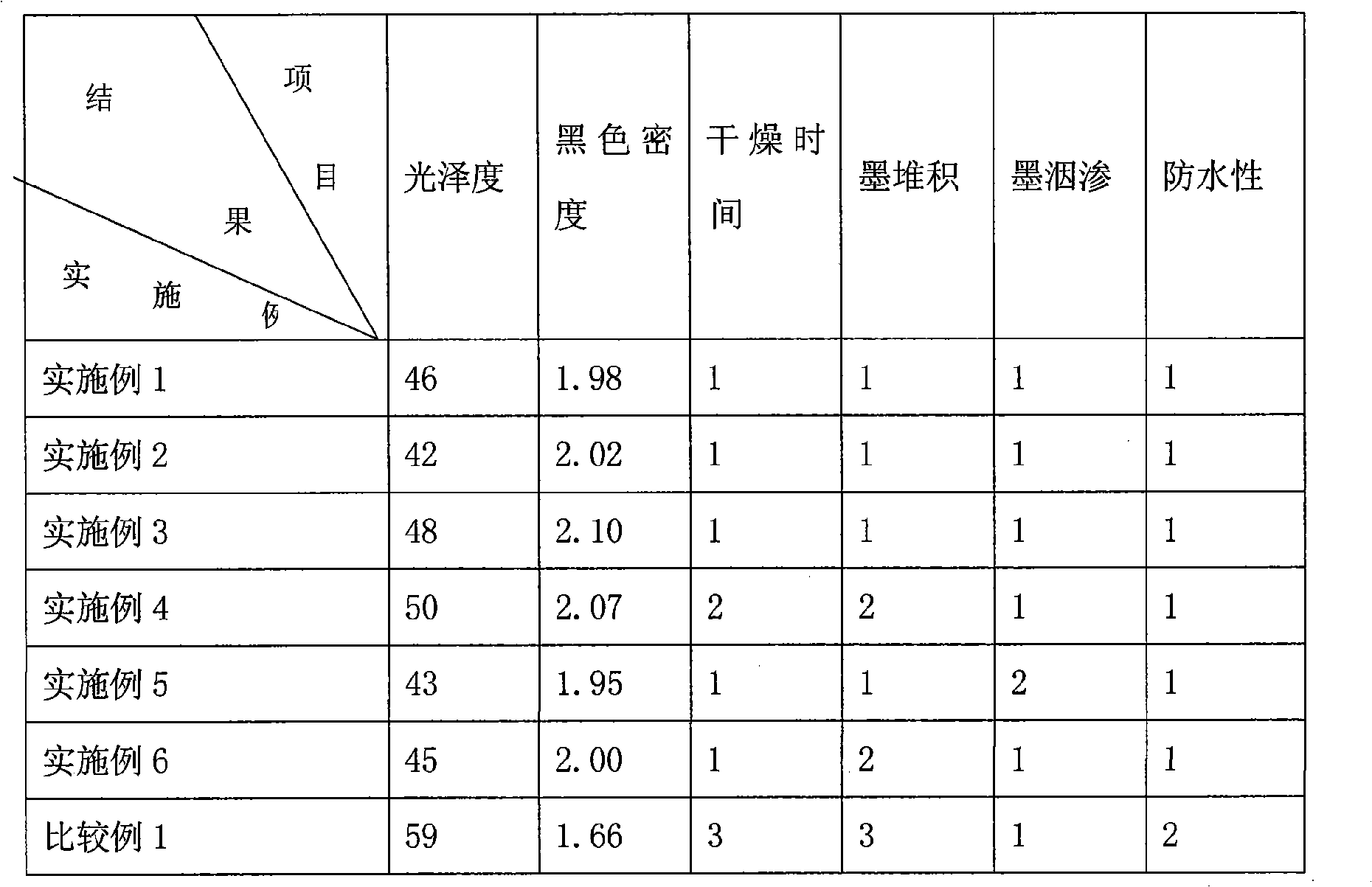

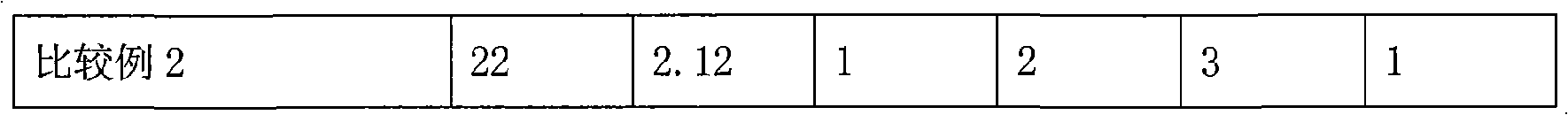

Examples

Embodiment 1

[0027] Coating solution formula:

[0028] 22 parts of silicon dioxide,

[0029] Colloidal silica sol (particle size 20nm) 78 parts,

[0030] 30 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%),

[0031] Ethylene / vinyl acetate polymer ethylene emulsion 15 parts,

[0032] 1 part of polydimethyldiallylammonium chloride cationic dispersant,

[0033] 0.8 part of defoamer (n-butanol),

[0034] Stripping agent (polyethylene wax) 0.2 parts,

[0035] 22 parts of silicon dioxide (trade name GASIL 23D, Singapore Ineos Silicon Dioxide Company, particle size 5 μm), 1 part of polydimethyldiallylammonium chloride cationic dispersant were added to 95 parts of deionized water, and used Disperse for 1 hour at a speed of 3000 rpm with a toothed disc disperser, then add 78 parts of colloidal silica sol, 30 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%), 15 parts of polyethylene / vinyl acetate emulsion, 0.8 part of defoamer (n-butanol), 0.2 part of poly...

Embodiment 2

[0037] Coating solution formula:

[0038] 40 parts of silicon dioxide,

[0039] 60 parts of colloidal alumina sol (particle diameter 20nm),

[0040] 50 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%),

[0041] Polyethylene / vinyl acetate polymer emulsion 15 parts,

[0042] 2 parts of polydimethyldiallylammonium chloride cationic dispersant,

[0043] Defoamer (BYK-022) 0.2 part,

[0044] Stripping agent (polyethylene wax) 0.2 parts,

[0045] Add 40 parts of silicon dioxide and 2 parts of polydimethyldiallylammonium chloride cationic dispersant to 180 parts of deionized water, disperse for 1 hour at a speed of 3000 revolutions per minute with a tooth disc disperser, and then add 60 Parts of colloidal alumina sol, 50 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%), 15 parts of polyethylene / vinyl acetate emulsion, 0.2 part of defoamer, 0.2 part of polyethylene wax stripper, add deionized water Prepare a coating liquid with a concentration...

Embodiment 3

[0047] Coating solution formula:

[0048] 45 parts of silicon dioxide,

[0049] Colloidal alumina sol (particle size 30nm) 45 parts,

[0050] 40 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%),

[0051] 30 parts of styrene-acrylonitrile emulsion,

[0052] Dispersant (polytrimethacryloyl ammonium chloride copolymer) 4 parts,

[0053] 0.8 part of defoamer (tributyl phosphate),

[0054] Stripping agent (polyethylene wax) 0.2 parts,

[0055] Add 45 parts of silicon dioxide (trade name AEROSIL 200, Evonik, Germany, particle size 0.2 μm) and 4 parts of polytrimethacrylammonium chloride copolymer dispersant to 200 parts of deionized water, and disperse with a toothed disc The machine was dispersed at a speed of 3000 revolutions per minute for 1 hour, and then added 45 parts of colloidal alumina sol, 40 parts of polyvinyl alcohol (PVA-1788 aqueous solution, content 10%), 30 parts of styrene-acrylonitrile emulsion, tributyl phosphate 0.8 part of ester, 0.2 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com