Dextran fatty acid graft, preparation method and application

A fatty acid and dextran technology, applied in the field of preparation of anti-tumor pharmaceutical compositions, can solve the problems of unfavorable target cell uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

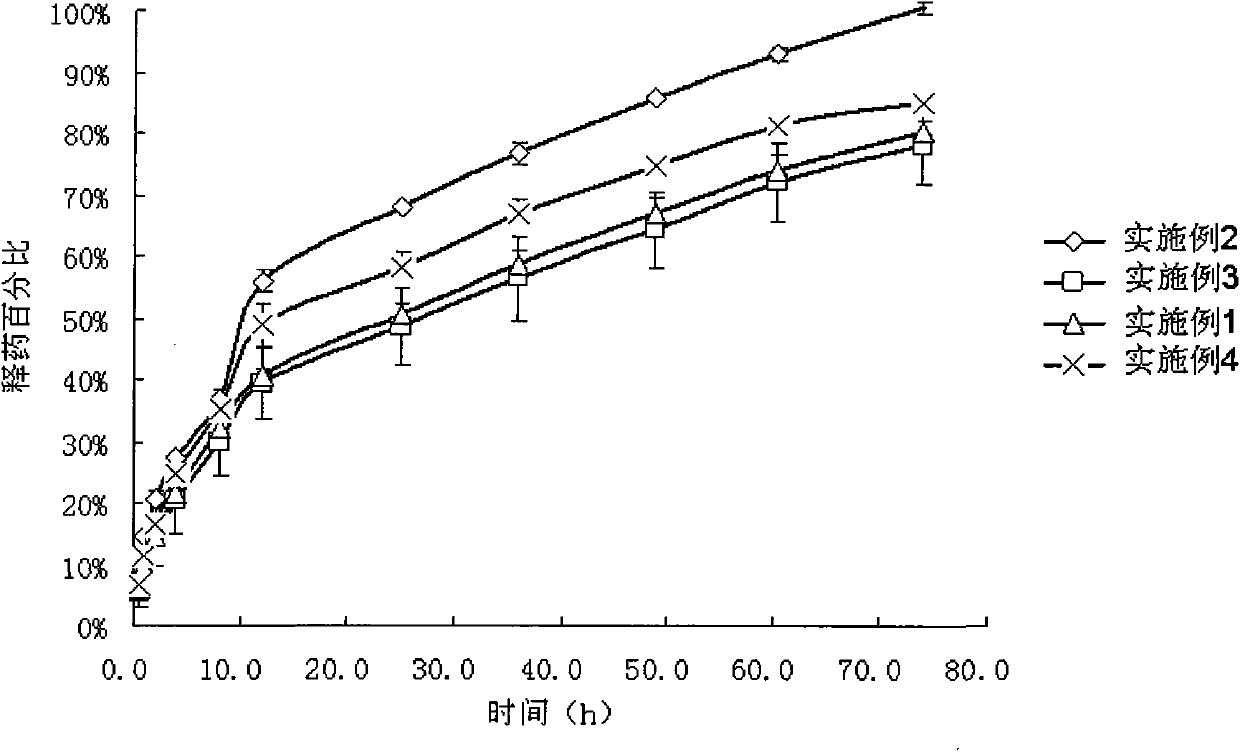

Embodiment 1

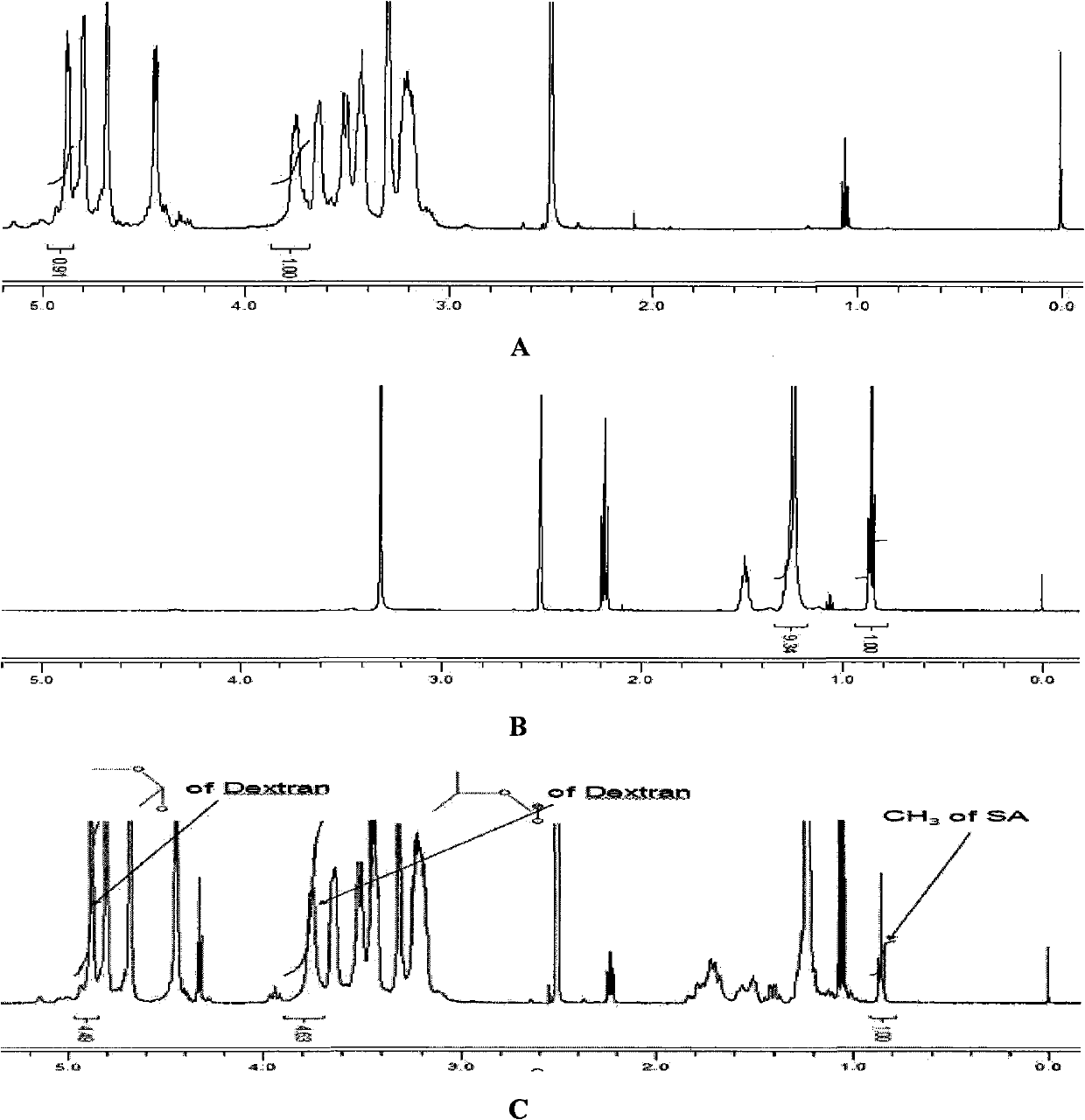

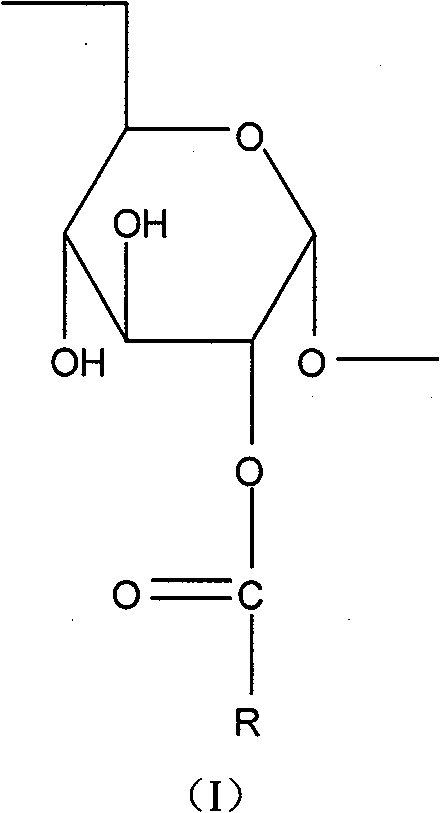

[0025] Accurately weigh 175.5mg of stearic acid, 381.8mg of DCC, 22.5mg of DMAP and 500mg of dextran (Mw=10000) into a 250ml dry round bottom flask, then add 45ml of dehydrated DMSO, heat and ultrasonically dissolve, add a small amount of anhydrous sodium sulfate. React at 60° C. for 8 h in a constant temperature heating magnetic stirrer, and protect with nitrogen. After the reaction, the reaction product was dialyzed for 48 hours with a dialysis bag (MWCO 3.5Kda, American Spectrum Laboratories Inc.), and the water was changed continuously to remove DMSO and water-soluble by-products. After dialysis, the reaction product was filtered with a 0.8 μm water membrane to remove insoluble substances such as DCC and then freeze-dried. The freeze-dried product was washed three times with ethanol to remove unreacted stearic acid. Finally, the reaction product is dissolved in deionized water and freeze-dried to obtain the dextran stearic acid graft

Embodiment 2

[0027] Accurately weigh 87.8mg of stearic acid, 191.5mg of DCC, 11.2mg of DMAP and 500mg of dextran (Mw=20000) into a 250ml dry round bottom flask, then add 45ml of dehydrated DMSO, heat and ultrasonically dissolve, add a small amount of anhydrous sodium sulfate. React at 60° C. for 8 h in a constant temperature heating magnetic stirrer, and protect with nitrogen. After the reaction, the reaction product was dialyzed for 48 hours with a dialysis bag (MWCO 3.5Kda, American Spectrum Laboratories Inc.), and the water was changed continuously to remove DMSO and water-soluble by-products. After dialysis, the reaction product was filtered with a 0.8 μm water membrane to remove insoluble substances such as DCC and then freeze-dried. The freeze-dried product was washed three times with ethanol to remove unreacted stearic acid. Finally, the reaction product is dissolved in deionized water and freeze-dried to obtain the dextran stearic acid graft

Embodiment 3

[0029]Accurately weigh 175.5mg of stearic acid, 381.8mg of DCC, 22.5mg of DMAP and 500mg of dextran (Mw=20000) into a 250ml dry round bottom flask, then add 45ml of dehydrated DMSO, heat and ultrasonically dissolve, add a small amount of anhydrous sodium sulfate. React at 60° C. for 8 h in a constant temperature heating magnetic stirrer, and protect with nitrogen. After the reaction, the reaction product was dialyzed for 48 hours with a dialysis bag (MWCO 3.5Kda, American Spectrum Laboratories Inc.), and the water was changed continuously to remove DMSO and water-soluble by-products. After dialysis, the reaction product was filtered with a 0.8 μm water membrane to remove insoluble substances such as DCC and then freeze-dried. The freeze-dried product was washed three times with ethanol to remove unreacted stearic acid. Finally, the reaction product is dissolved in deionized water and freeze-dried to obtain the dextran stearic acid graft

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com