Inner surface coating technique of medicinal glass bottle

A technology for medicinal glass bottle and inner surface, applied to the field of inner surface coating process, can solve problems such as inability to remove, residue residue, drug stability, etc., to ensure stability and purity, reduce drug residue, and reduce hanging. The effect of the wall phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

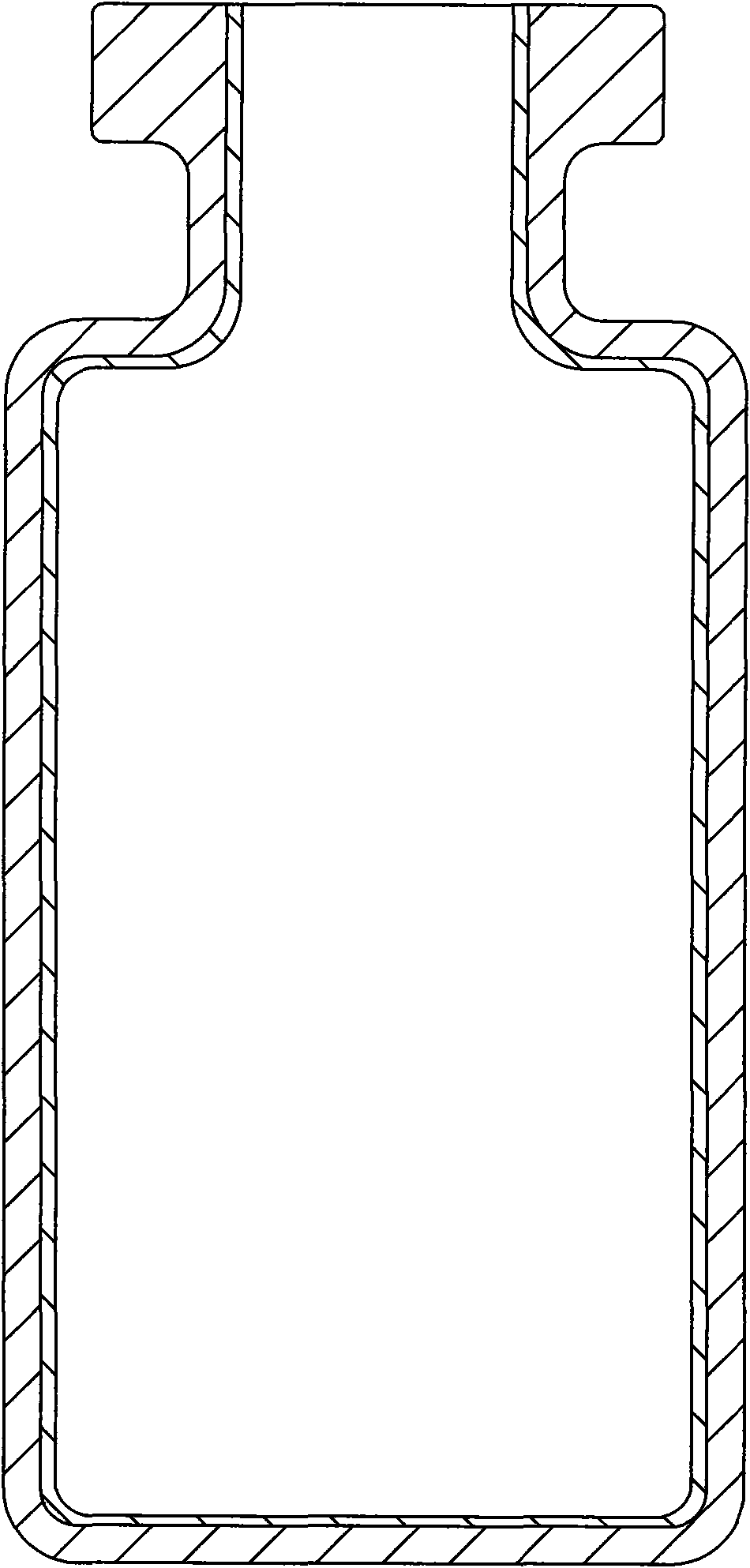

[0024] refer to figure 1 , a film coating process for the inner surface of a medicinal glass bottle, comprising the following steps: adding water to an organosiloxane to prepare a 5wt% dispersion solution, filling the dispersion solution in a medicinal glass bottle, and maintaining After 30 minutes, pour out the solution, heat the glass bottle to 400°C, and keep it solidified for 30 minutes to obtain the final product.

[0025] The organosiloxane is polydimethylsiloxane.

[0026] The medicinal glass bottle is pretreated before adding the solution. The pretreatment is to wash with dilute alkali first, and then to wash at high temperature with purified water.

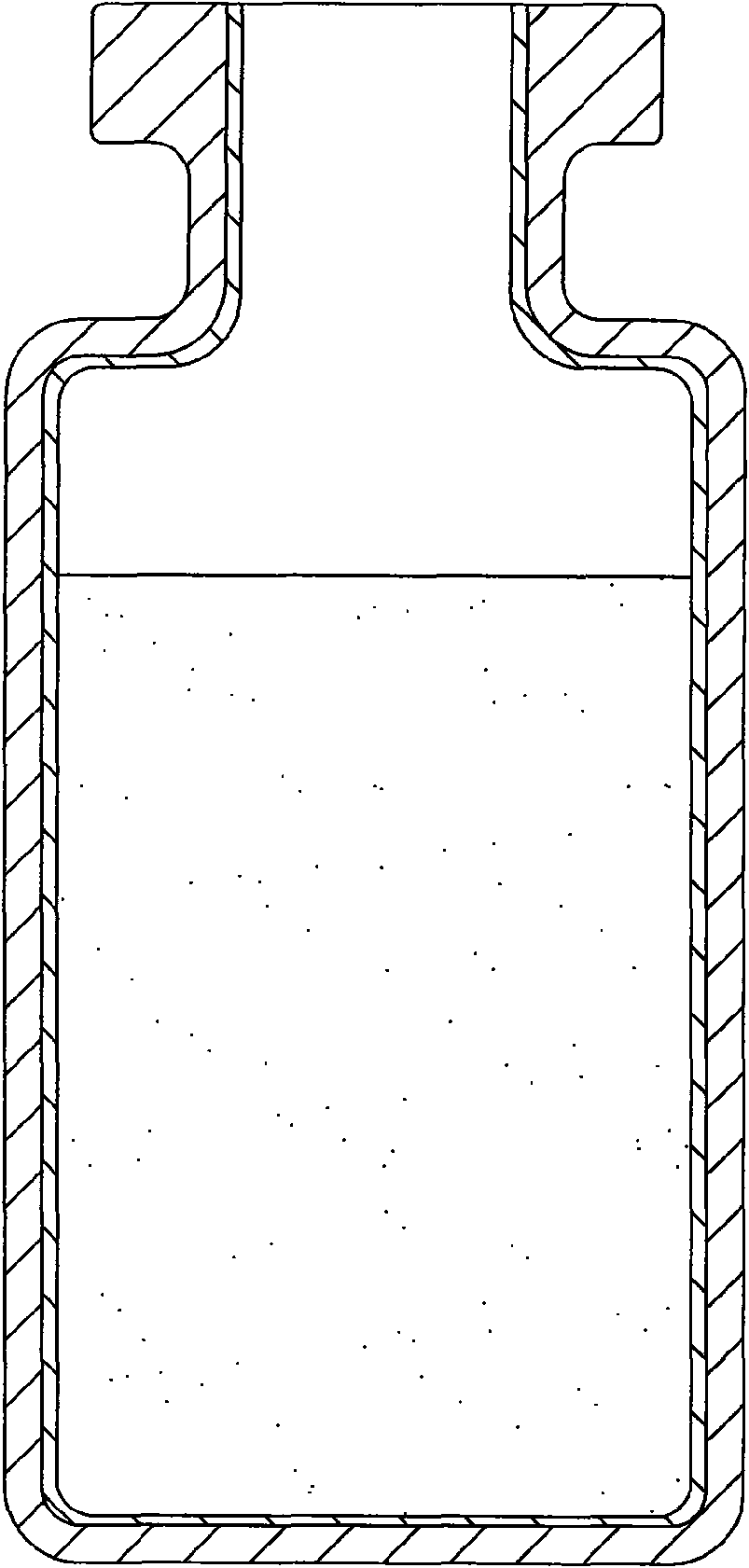

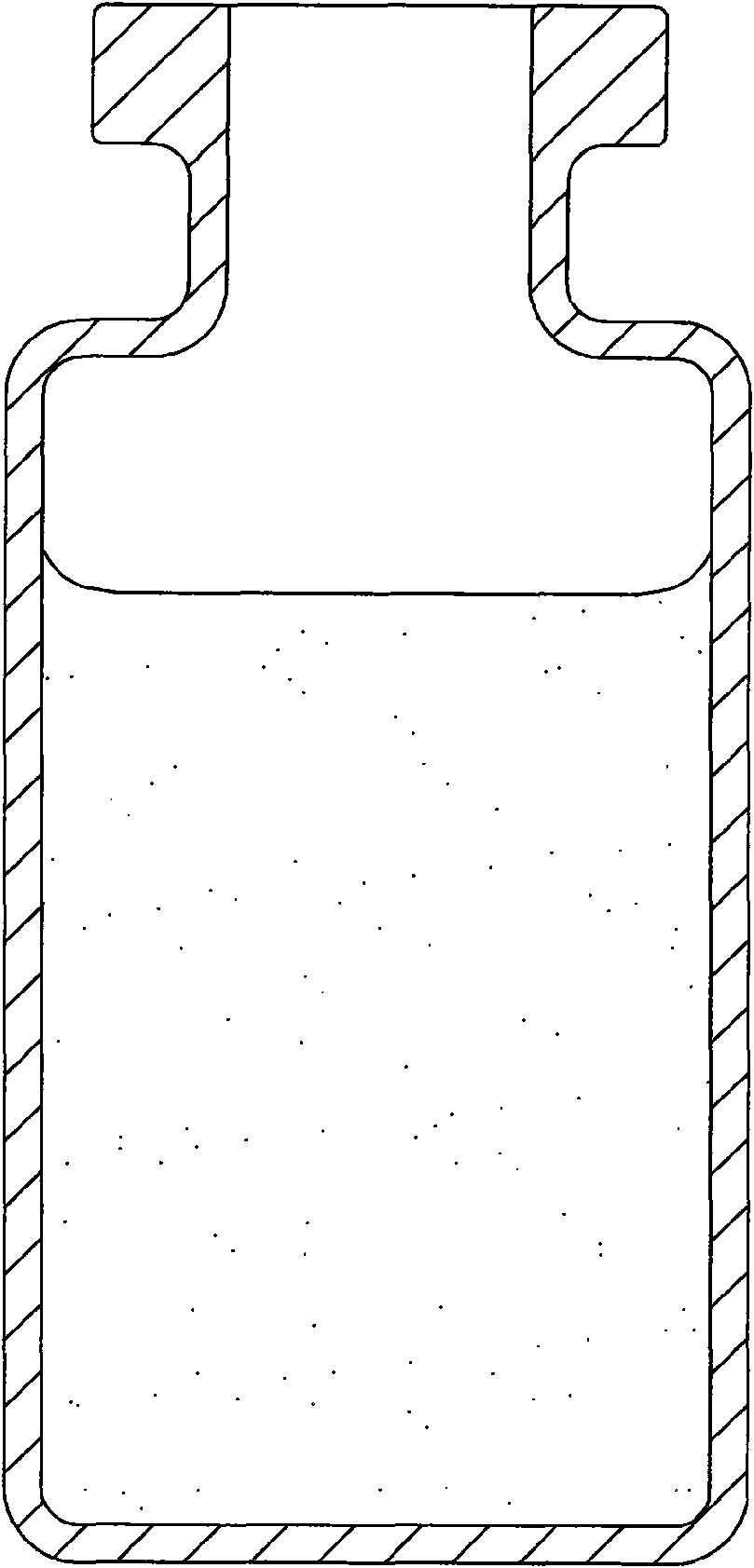

[0027] Glass bottle structure after coating (such as figure 1 shown). Due to the hydrophobic properties of the polysiloxane film material, the liquid level in the bottle is very smooth (such as figure 2 shown), while the uncoated injection bottle has a concave liquid surface due to the hydrophilicity of the glass (s...

Embodiment 2

[0029] refer to figure 1 , a film coating process for the inner surface of a medicinal glass bottle, comprising the steps of: taking an organosiloxane and adding a dispersant and then adding water to prepare an 8wt% dispersion solution, filling the dispersion solution in a medicinal glass bottle, and maintaining After 10 minutes, the solution was poured out, the glass bottle was heated to 360°C, and kept solidified for 50 minutes to obtain the final product.

[0030] The organosiloxane is polydimethylsiloxane.

[0031] The medicinal glass bottle is pretreated before adding the solution. The pretreatment is washing with dilute acid first, and then washing at high temperature with purified water.

Embodiment 3

[0032] Embodiment 3 water resistance test

[0033] According to the national drug packaging container (material) method standard (YBB00242003) of the State Food and Drug Administration, low borosilicate glass bottles, neutral borosilicate glass bottles, high borosilicate glass bottles in the prior art, and embodiment 1 of the present invention The water resistance of the inner surface of the obtained siliconized coated glass bottle was measured, and the results are shown in Figure 4.

[0034] After the film is formed, the water resistance of the inner surface of the siliconized coating control injection bottle of the technical product of the project is significantly improved, and the precipitation of alkaline oxides is significantly reduced. Because the content of diboron trioxide in low borosilicate glass, neutral borosilicate glass and high borosilicate glass is 5-8%, 8-12%, and 12.5% or more respectively, the water resistance is enhanced in turn, and the precipitation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com