Inductance coupling coil and plasma processing device adopting same

An inductively coupled coil and plasma technology, applied in the field of microelectronics, can solve problems such as unpredictable processing/processing results, changes in reaction conditions, and undesired results, and achieve uniform processing/processing results, improve quality, and reduce the effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to enable those skilled in the art to better understand the technical solution of the present invention, the inductively coupled coil and the plasma processing device using the inductively coupled coil provided by the present invention will be described in detail below with reference to the accompanying drawings.

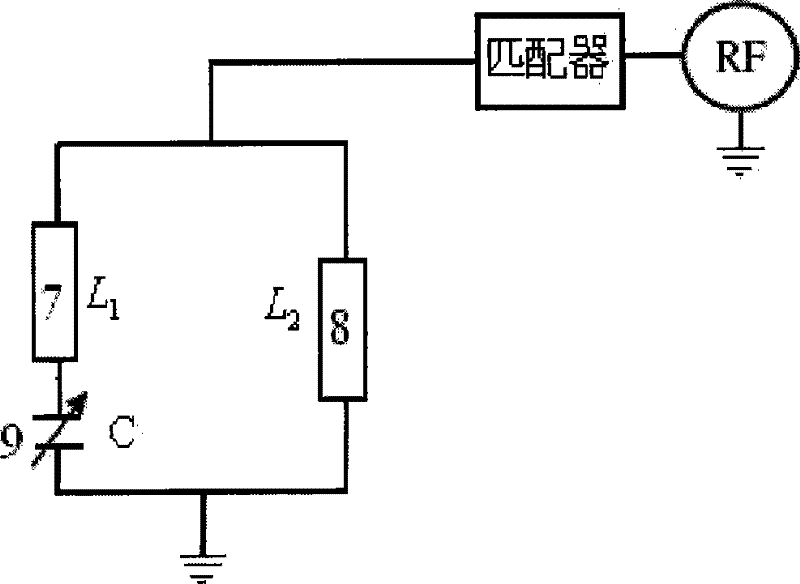

[0055] see image 3 , the inductively coupled coil provided by the present invention includes an inner winding part 7 (corresponding to the inductance L 1 ) and the outer winding part 8 (corresponding to the inductance L 2 ), and the inner winding part 7 is connected in series with the adjustable capacitor 9 to form a first coil branch, the outer winding part 8 forms a second coil branch, and the first coil branch and the second coil branch are connected in parallel.

[0056] The working principle of the above-mentioned inductively coupled coil is as follows: in the plasma ignition stage, the adjustable capacitor 9 is adjusted so that its capacitanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com