High-temperature resistant air cooling smoke gate device

A high temperature resistant gate device technology, which is applied in the direction of valve device, valve heating/cooling device, valve operation/release device, etc., can solve the problems of high operation and maintenance costs, short gate life, inconvenient replacement, etc. , to achieve the effect of strong operability and practicability, reliable operation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

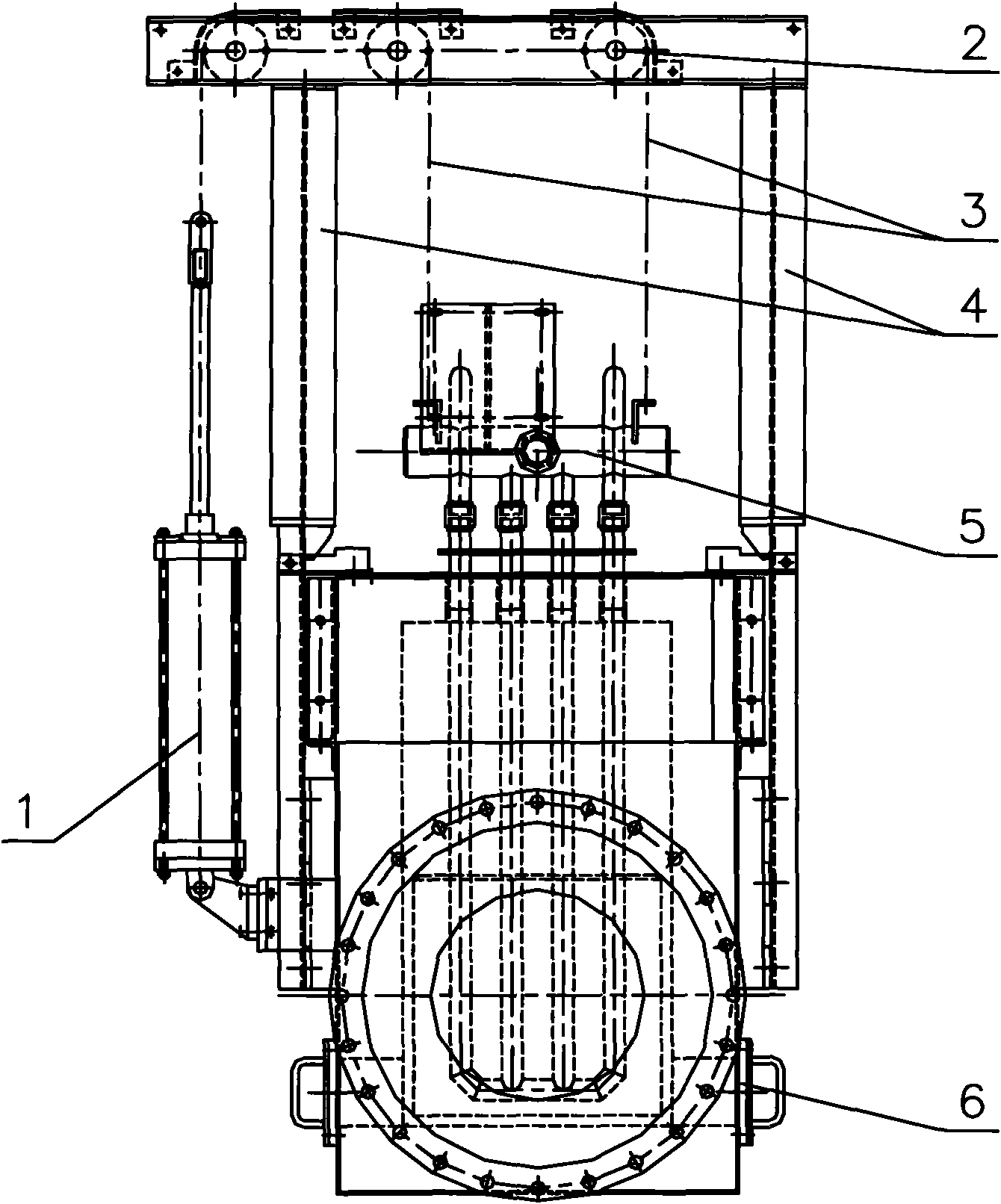

[0028] In various aluminum melting furnaces, holding furnaces or hybrid furnaces, as long as gas or liquid fuel is used as the heat supply source required by the furnace, no matter what kind of combustion method is used, all or part of the high-temperature flue gas will be emitted. In order to effectively control To reduce the emission of flue gas and improve the thermal efficiency of the furnace, it is necessary to use a smoke lock and effectively control the opening of the smoke lock in real time during the production process to adjust the internal pressure of the furnace. The invention provides a set of high-temperature-resistant air-cooled smoke gate device with complete structure and reasonable structure, which is installed on the flue and effectively participates in the control of the pressure in the furnace.

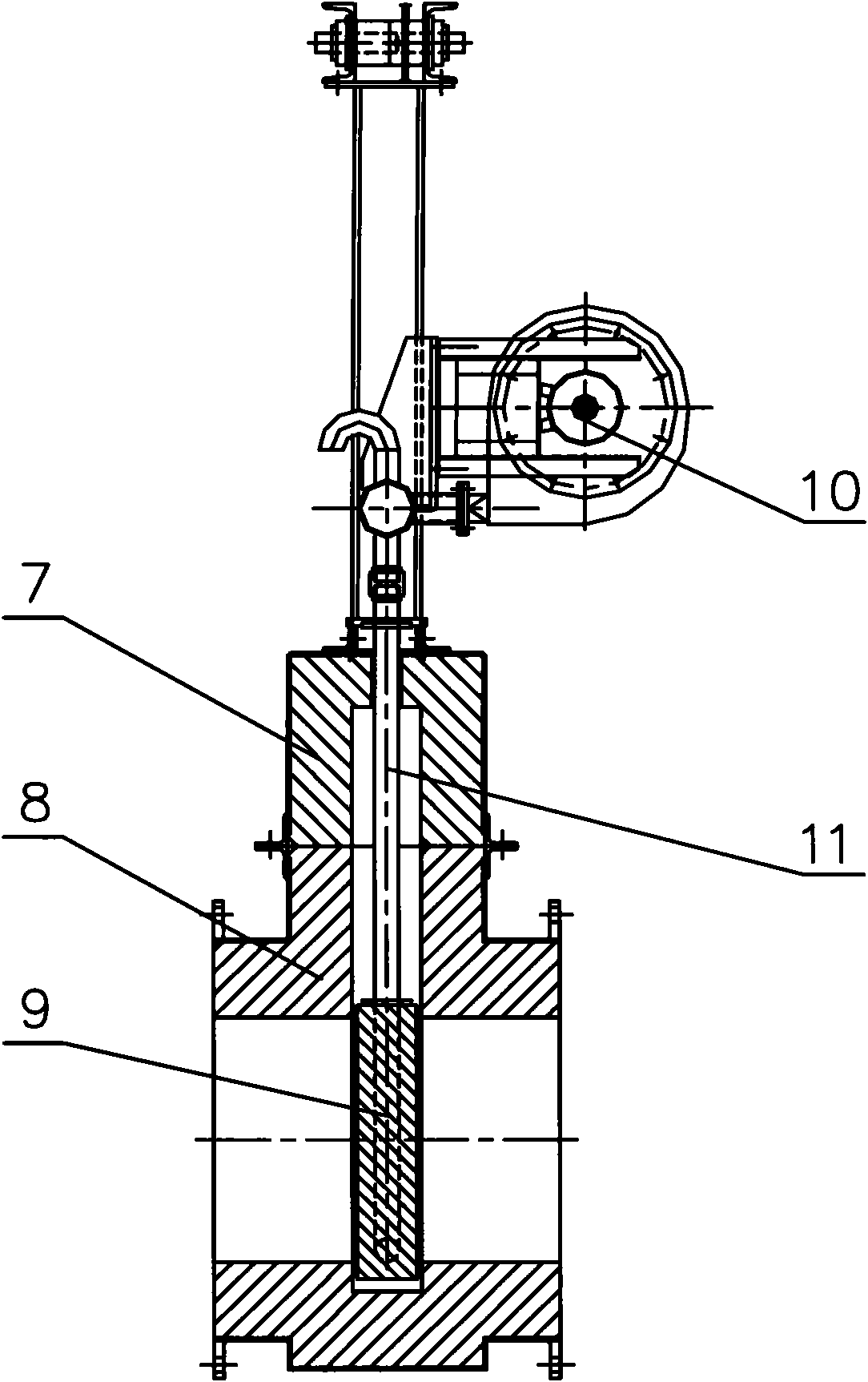

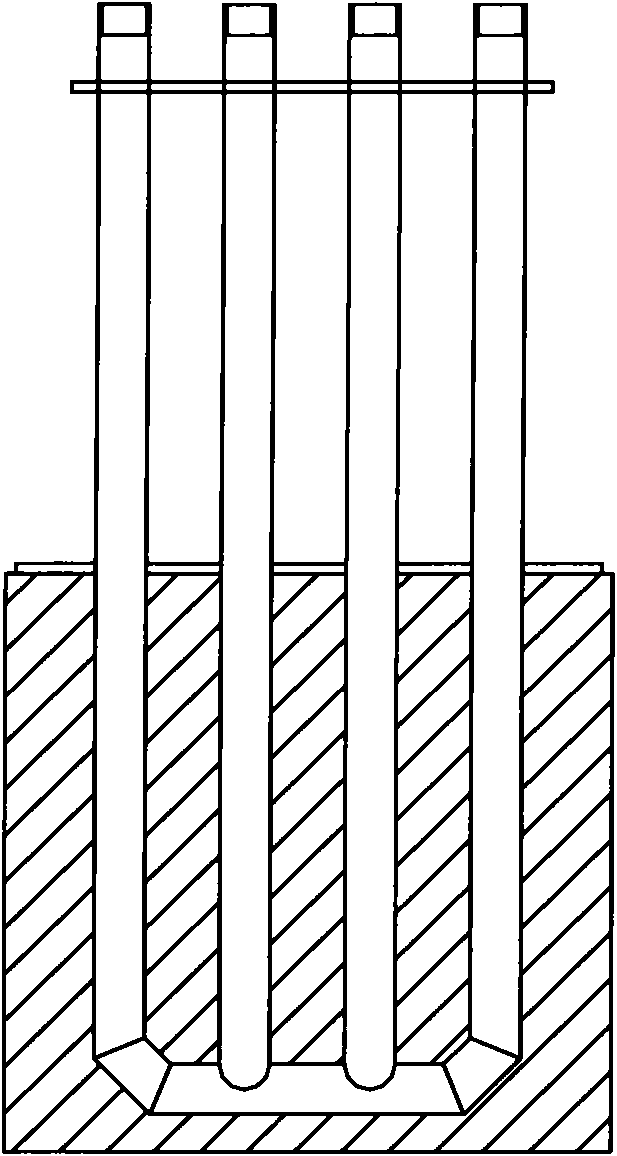

[0029] Such as Figure 1 to Figure 5 As shown, the high temperature resistant air-cooled smoke gate device of the present invention includes: driving cylinder 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com