Method for reinforcing concrete column by expanding section of coated concrete-filled steel tube (CFST)

A technology of steel pipe concrete and concrete columns, which is applied in construction, building maintenance, building construction, etc., can solve the problems of poor collaborative deformation performance, low performance utilization rate of outsourcing steel, and small improvement in structural plasticity, so as to improve bearing capacity and Stiffness, elimination of additional load effects, improvement of plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

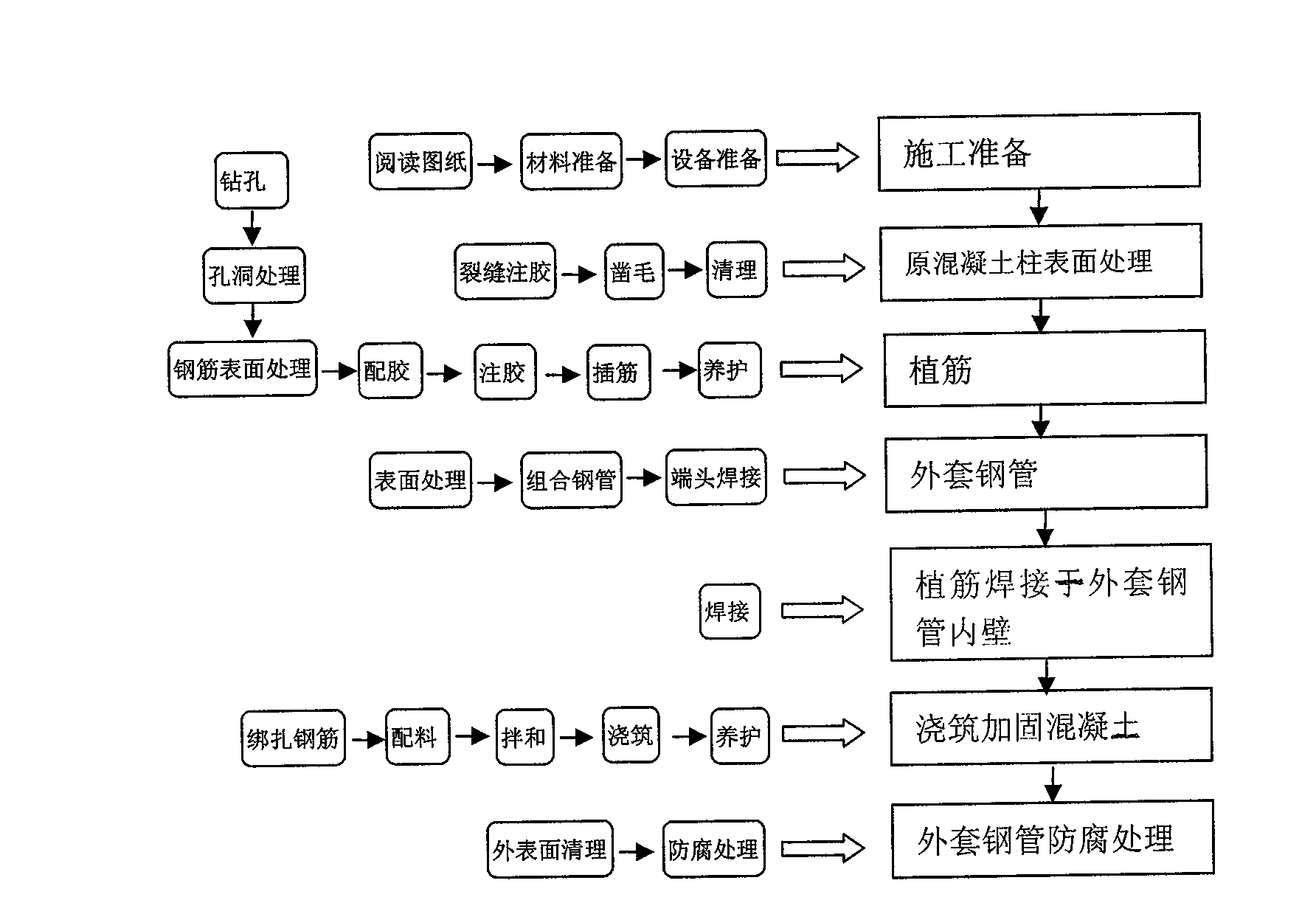

[0030] The present invention is further described in conjunction with accompanying drawing, main construction procedure is:

[0031] Construction preparation → surface treatment of the original concrete column → planting reinforcement → outer casing steel pipe → welding the planting reinforcement and the inner wall of the outer casing steel pipe → pouring reinforced concrete → anticorrosion and exterior decoration treatment on the outer surface of the outer casing steel pipe.

[0032] The following is a detailed description with schematic diagrams and examples:

[0033] (1) Construction preparation: read the drawings, prepare steel, cement and other materials and construction tools required for the project before construction.

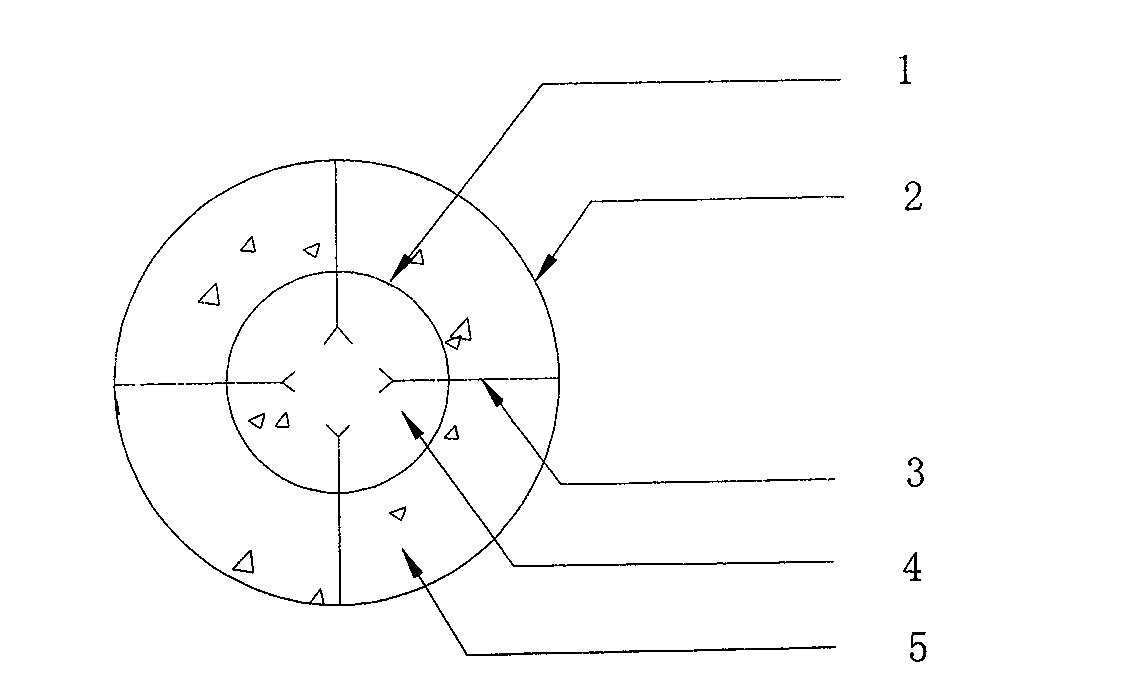

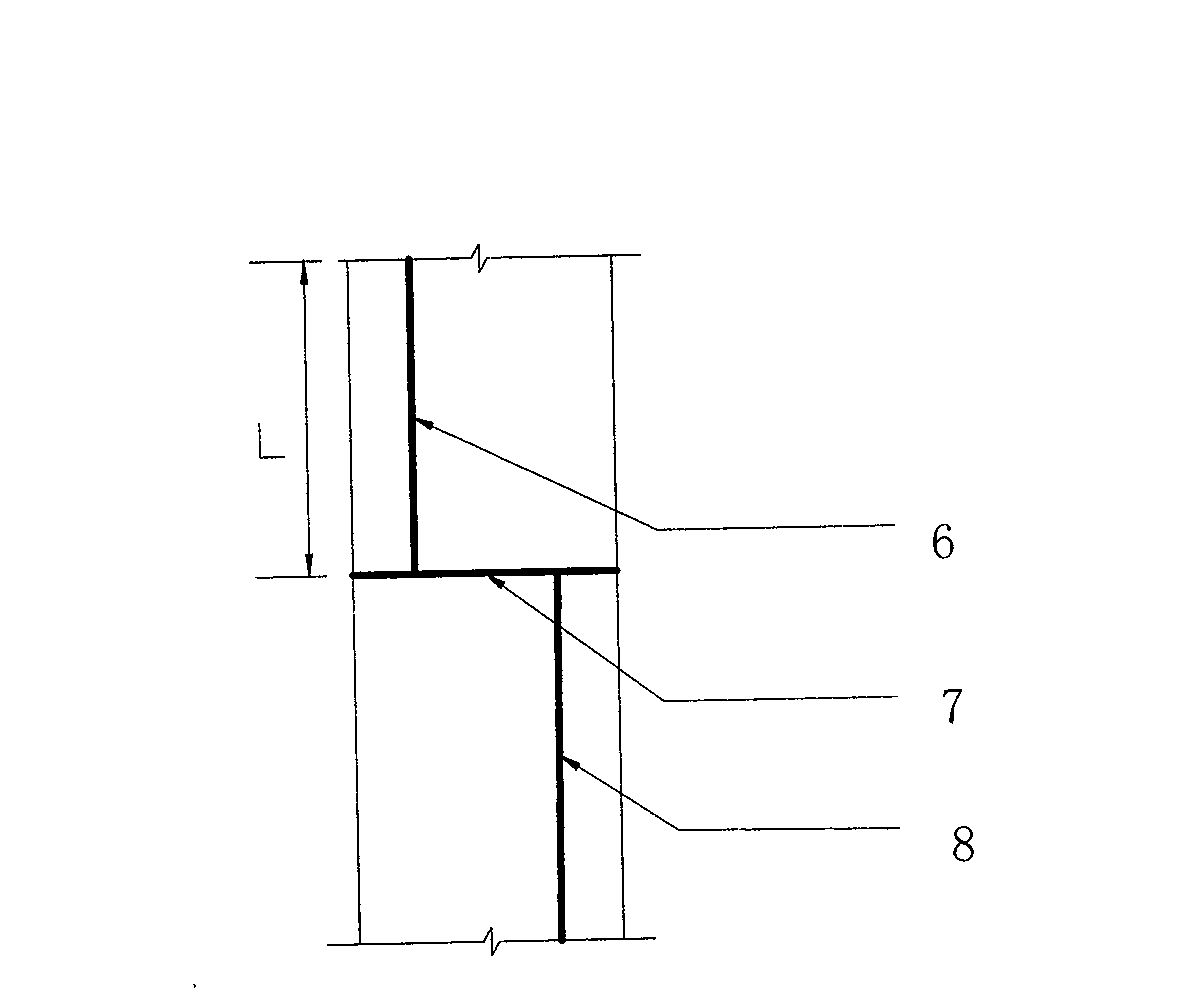

[0034] (2) Surface treatment of the original concrete column; first, grout the fine cracks and deep cracks on the surface of the original concrete column 4 with structural joint glue, and chisel the surface of the original concrete column 4 after curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com