Carbonized floor manufacturing method

A production method and flooring technology, applied in the direction of charcoal burning/combustion, wood compression, wood processing equipment, etc., can solve the problems of affecting human health, increasing environmental pollution, time-consuming and labor-intensive, etc., and achieve environmental protection, low cost, and pest control. good moth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

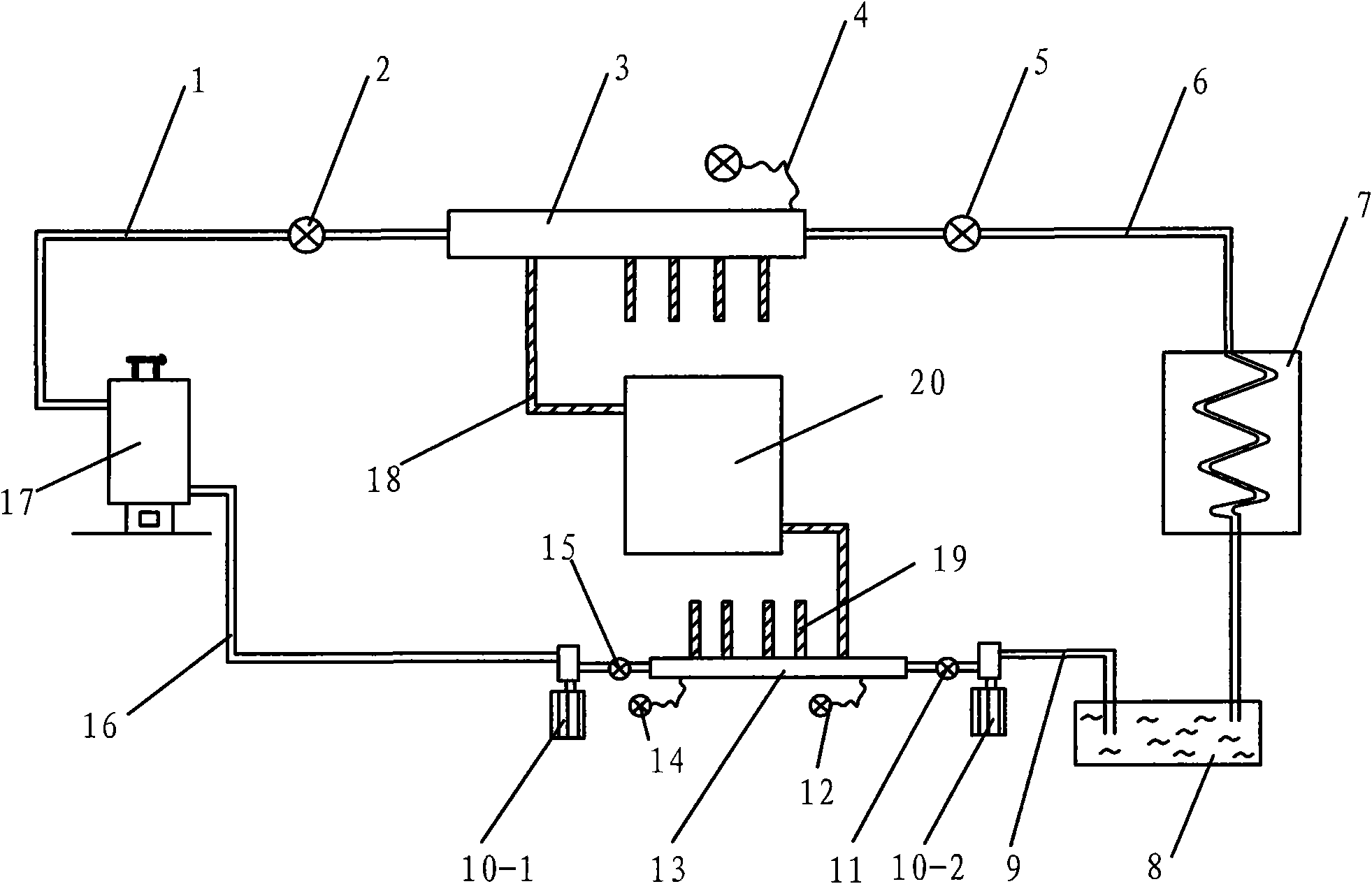

[0030] Embodiment 1: as figure 1 The shown heat press machine comprises: a heat press chamber, an oil guide part connected with the heat press chamber, a hot oil device connected with the oil guide part, the oil guide part is also connected with a cold oil device, and the heat The press chamber includes a hot press plate 20, which is made of steel, with a length of 2500 mm, a width of 2000 mm, and a height of 18.5 mm.

[0031] A sealing strip is respectively installed on the four sides of the hot pressing plate 20, and the sealing strip is made of steel, and two of them installed on the long sides are fixed sealing strips, and the fixed sealing strip is 40 mm wide, 2500 mm long, and 18.5 mm high. mm, the other two are movable sealing strips with a width of 40mm, a length of 1900mm, and a height of 18.5mm. The length of the movable sealing strip is 20mm shorter than the gap between the two fixed sealing strips, so that there is a 10mm gap between the left and right sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com