Sn-Ag-Cu lead-free solder containing Nd, Li, As and In

A lead-free solder, sn-ag-cu technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problem of very limited improvement of the comprehensive performance of solder alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

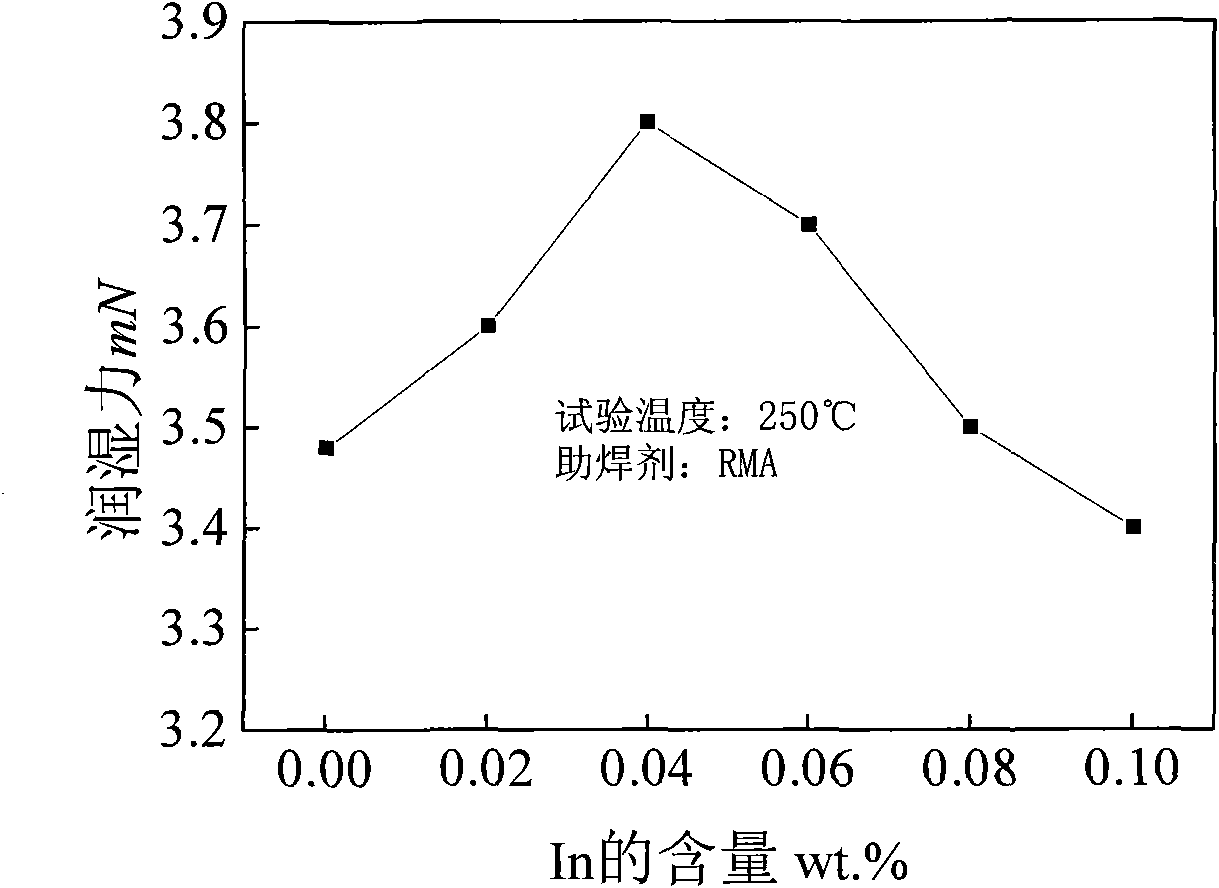

[0029] A kind of Sn-Ag-Cu lead-free solder containing Nd, Li, As, In, proportioned by mass fraction, its composition is: 3.7% Ag, 0.7% Cu, 0.001% Nd, 0.05% Li, 0.05% As , 0.08% In, 0.05% Pb, and the balance is Sn. The solidus temperature of the "Sn-Ag-Cu lead-free solder containing Nd, Li, As, and In" obtained by the above composition ratio is about 213°C, and the liquidus temperature is about 218°C (considering the experimental error), Combined with commercially available no-clean flux, it has excellent wettability and spreadability on copper and PCB boards.

Embodiment 2

[0031] A kind of Sn-Ag-Cu lead-free solder containing Nd, Li, As, In, proportioned by mass fraction, its composition is: 3.6% Ag, 0.9% Cu, 0.025% Nd, 0.03% Li, 0.05% As , 0.1% In, 0.02% Pb, and the balance is Sn. The solidus temperature of the "Sn-Ag-Cu lead-free solder containing Nd, Li, As, and In" obtained by the above composition ratio is about 212°C, and the liquidus temperature is about 217°C (considering the experimental error), Combined with commercially available no-clean flux, it has excellent wettability and spreadability on copper and PCB boards.

Embodiment 3

[0033] A kind of Sn-Ag-Cu lead-free solder containing Nd, Li, As, In, proportioned by mass fraction, its composition is: 3.4% Ag, 0.5% Cu, 0.05% Nd, 0.02% Li, 0.05% As , 0.001% In, 0.001% Pb, and the balance is Sn. The solidus temperature of the "Sn-Ag-Cu lead-free solder containing Nd, Li, As, and In" obtained by the above composition ratio is about 212°C, and the liquidus temperature is about 216°C (considering the experimental error), Combined with commercially available no-clean flux, it has excellent wettability and spreadability on copper and PCB boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com