Permanent magnetic independent generator

A generator and permanent magnet technology, applied to electrical components, electromechanical devices, synchronous machine parts, etc., can solve problems such as limited social benefits and restrictions on mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

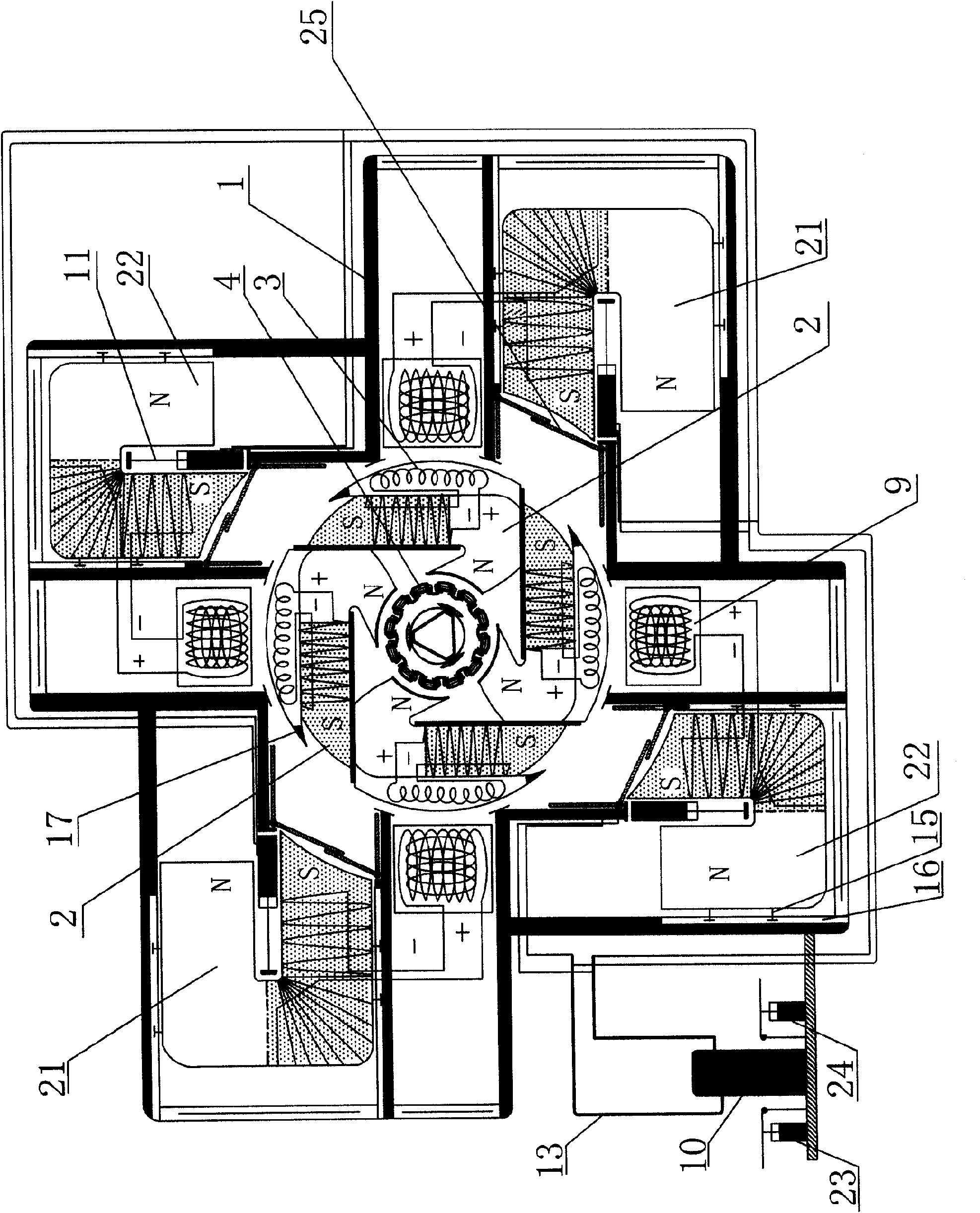

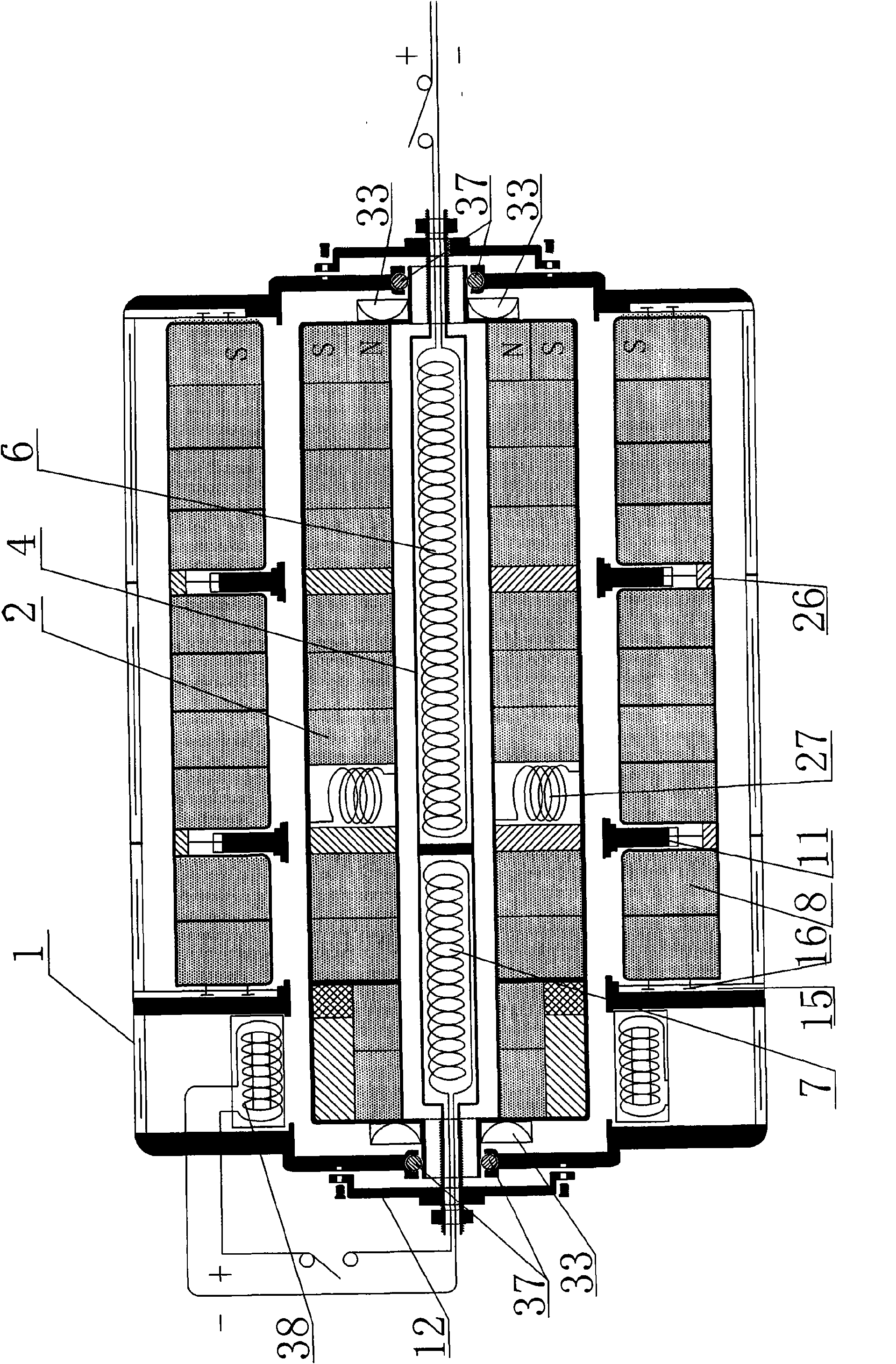

[0070] A permanent magnet independent generator, such as figure 1 , figure 2 , Image 6 and Figure 10 Shown, comprise housing 1, rotor 34 and stator 4, stator 4 is arranged on the center of generator, rotor 34 is arranged on the periphery of stator 4, rotor 34 periphery is provided with mover 35, mover 35 is made up of several mover magnets 8 and The mover magnet coil 9 is composed of the rotor 34. The rotor 34 is composed of several rotor magnets 2 and the rotor magnet coil 3. The mover magnet chute 16 is arranged on the inner wall of the housing 1, and the mover magnet 8 is set in the mover magnet fixing sleeve. Inside 14, a sliding pin 15 is arranged on the outer side of the moving magnet fixing sleeve 14, and the sliding pin 15 is embedded in the moving magnet chute 16 so that the sliding pin 15 and the moving magnet chute 16 form a sliding connection, and the groove of the moving magnet 8 is connected through the Part 26 is connected with hydraulic sub-top 11, and hy...

Embodiment 2

[0072] like figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 15 As shown, the mover 35 is arranged in the sliding groove in the generator casing 1, and four rows of mover magnets 8 and mover solid magnetic coils 9 are arranged around the circumference, and each row of movers in the longitudinal direction is composed of twelve single U-shaped mover magnets 8 and correspondingly configured mover solid-magnet coils 9. This is a better quantity setting. The mover row is composed of four single U-shaped mover magnets 8 and the corresponding mover fixed-magnet coils 9 in a circle. Each row When the mover is packaged as a whole, two connectors 26 that can connect the hydraulic sub-jack 31 of the hydraulic sub-top 11 are respectively provided at the concave U-shaped bottom of the U-shaped mover magnet 8, and each row of movers 35 is in the U-shaped The bottom is divided longitudinally into two hydraulic sub-tops 11, and the hydraulic sub-tops ar...

Embodiment 3

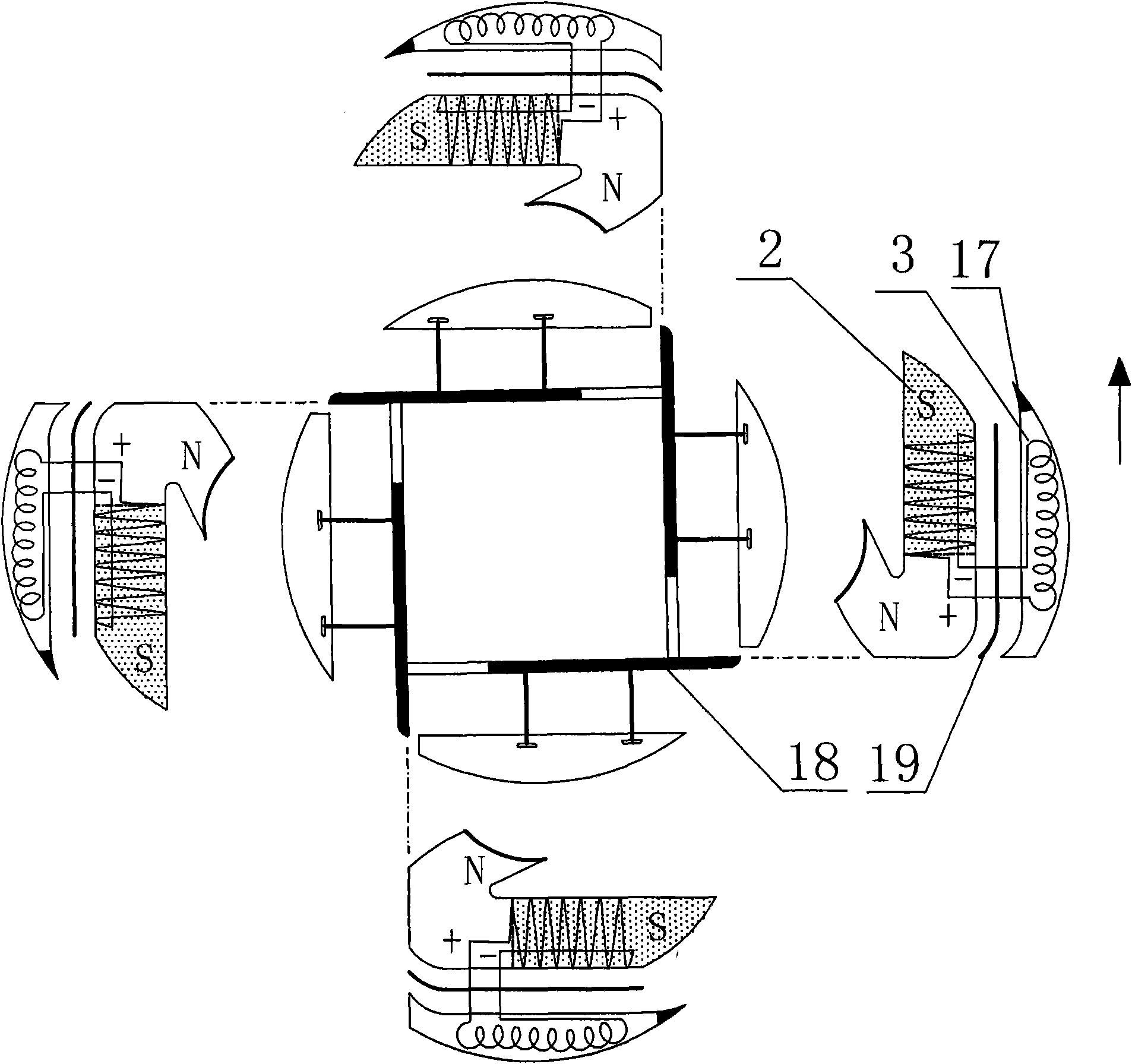

[0074] like figure 1 , figure 2 , image 3 , Figure 14 and Figure 15As shown, the rotor 34 is arranged in the middle layer of the generator, and its rotor 34 is longitudinally provided with twelve peripheral rotors, which is a preferred number setting (in actual use and manufacture, the number of longitudinal peripheral rotors can be increased or increased according to the needs of actual conditions. reduced, but the same as the number of individual movers arranged in the longitudinal direction of the movers), each rotor is composed of four single rotor magnets 2 and four correspondingly configured rotor solid magnetic coils 3, wherein the S pole of one rotor magnet 2 The side surface is close to the outer surface of the N pole of the previous rotor magnet 2, and the rotor solid magnetic coil 3 is arranged close to the outer side of the S pole. These four form a circle to form a tubular circumferential rotor. The purpose is to make the tubular circumferential rotor form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com