Rotor weight self-adaptive type permanent magnet thrust bearing

A technology of rotor weight and thrust bearing, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., to achieve the effect of easy installation, not easy to lose magnetism, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

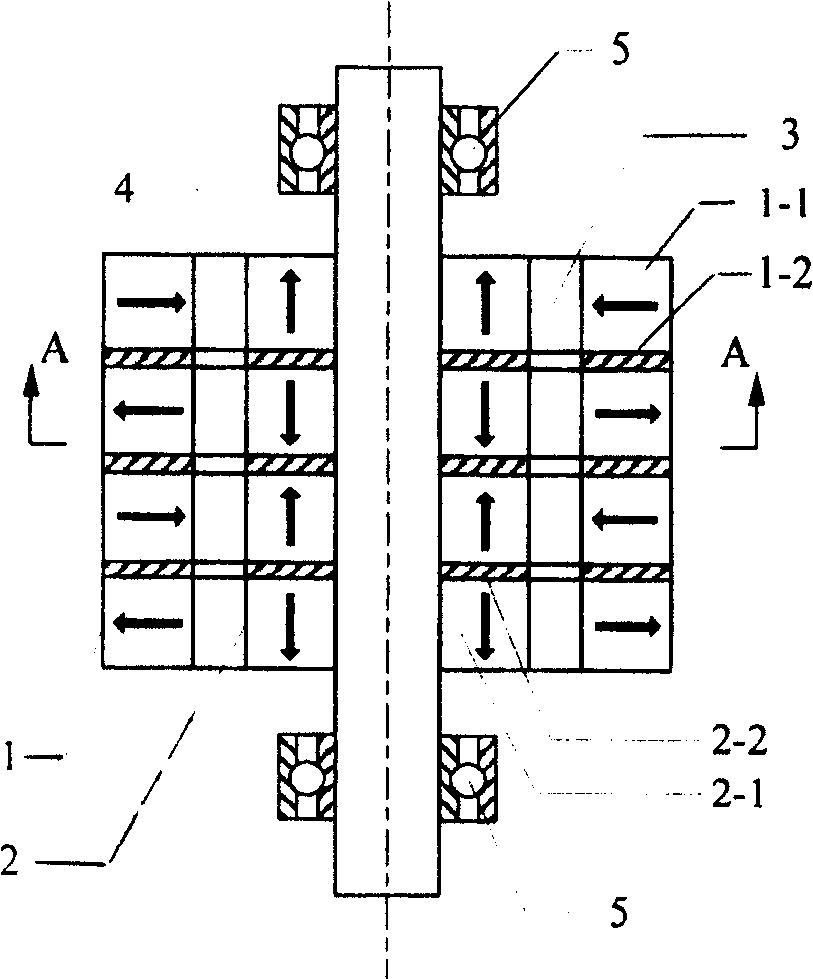

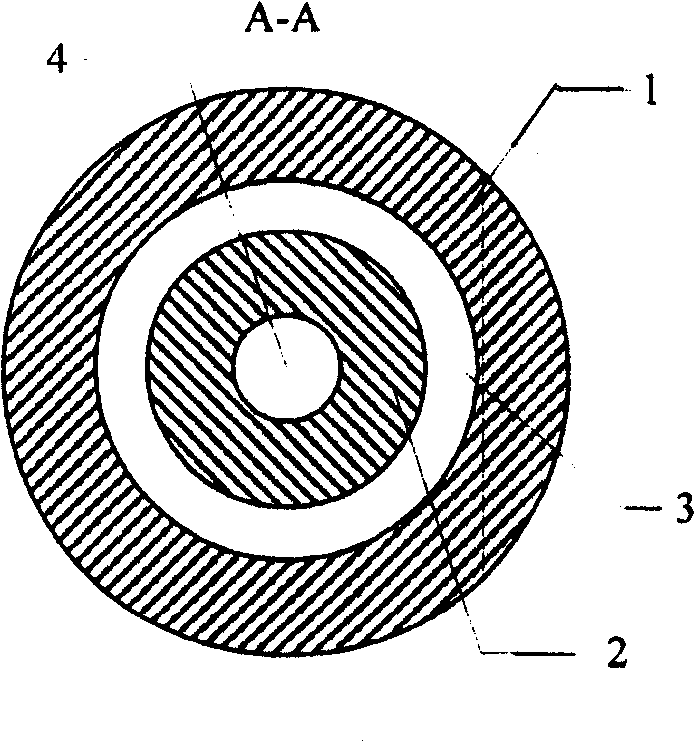

[0016] refer to figure 1 , figure 2 , the permanent magnet thrust bearing of the self-adaptive rotor weight of the present invention comprises a stator 1, a rotor 2 and an auxiliary radial bearing 5, an air gap 3 is provided between the stator and the rotor, and the stator 1 is composed of n pairs of stacked permanent magnets with alternate magnetization directions. The magnetic ring 1-1 and the non-magnetic ring 1-2 sandwiched between the adjacent permanent magnetic rings are composed; The non-magnetic ring 2-2 between the adjacent permanent magnetic rings is formed, n and m are natural numbers, figure 1 The logarithm of the stator permanent magnet ring is equal to the logarithm of the rotor permanent magnet ring, and 4 is the rotating shaft in the figure.

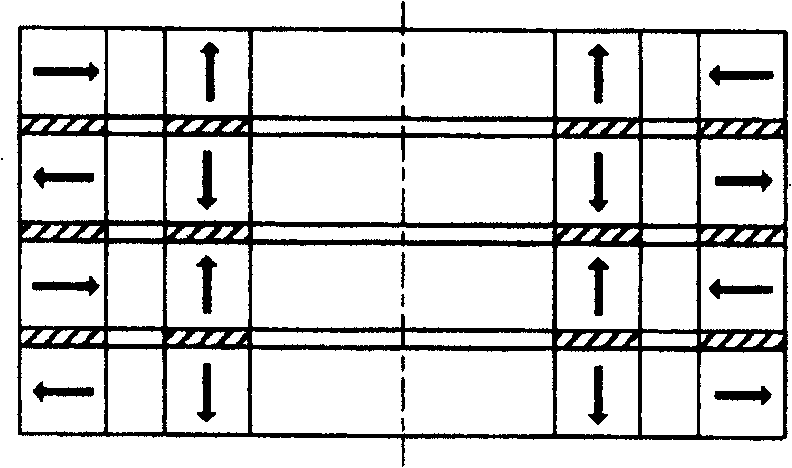

[0017] The magnetization directions of the stator and rotor permanent magnet rings can be as follows: Figure 3 ~ Figure 6 The four combinations shown: the stator permanent magnet ring is radially magnetized, the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com