Method for preventing ice from covering surface of power transmission bare conductor

A bare wire and ice-coating technology is applied in the field of effectively suppressing the formation of icing on the surface of bare wires for power transmission. Ultra-hydrophobic, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

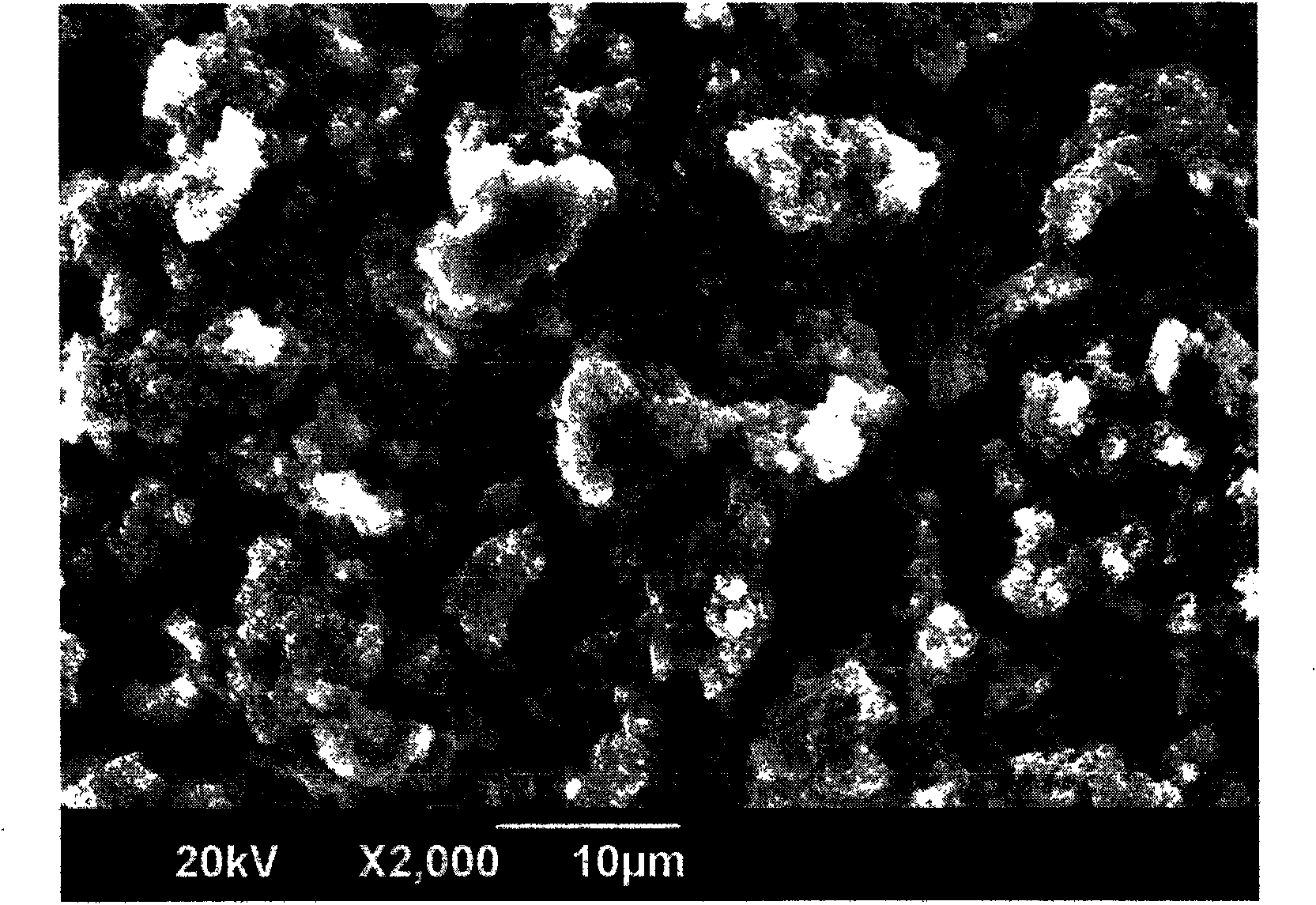

[0018] Put the aluminum wire (length 15cm, Φ2.76mm) in 20wt%, 25wt%, 30wt% mixed acid etchant for 1.5min, then wash it with ultrasonic pure water, dry it at 70°C for 30min, then dip it in 1.5 Wt% or 2.5wt% fluorosilane is low surface energy modification in the solution of fluorosilane FAS-17 for 12h, and then treated at 100°C for 2h to construct a super-hydrophobic coating with micro-nano pore structure on its surface, Surface microstructure of superhydrophobic anti-icing coating (such as image 3 shown). The mixed acid etchant is formed by mixing hydrofluoric acid, hydrochloric acid, nitric acid and sulfuric acid in a volume ratio of 1:3.5:1:1.

Embodiment 2

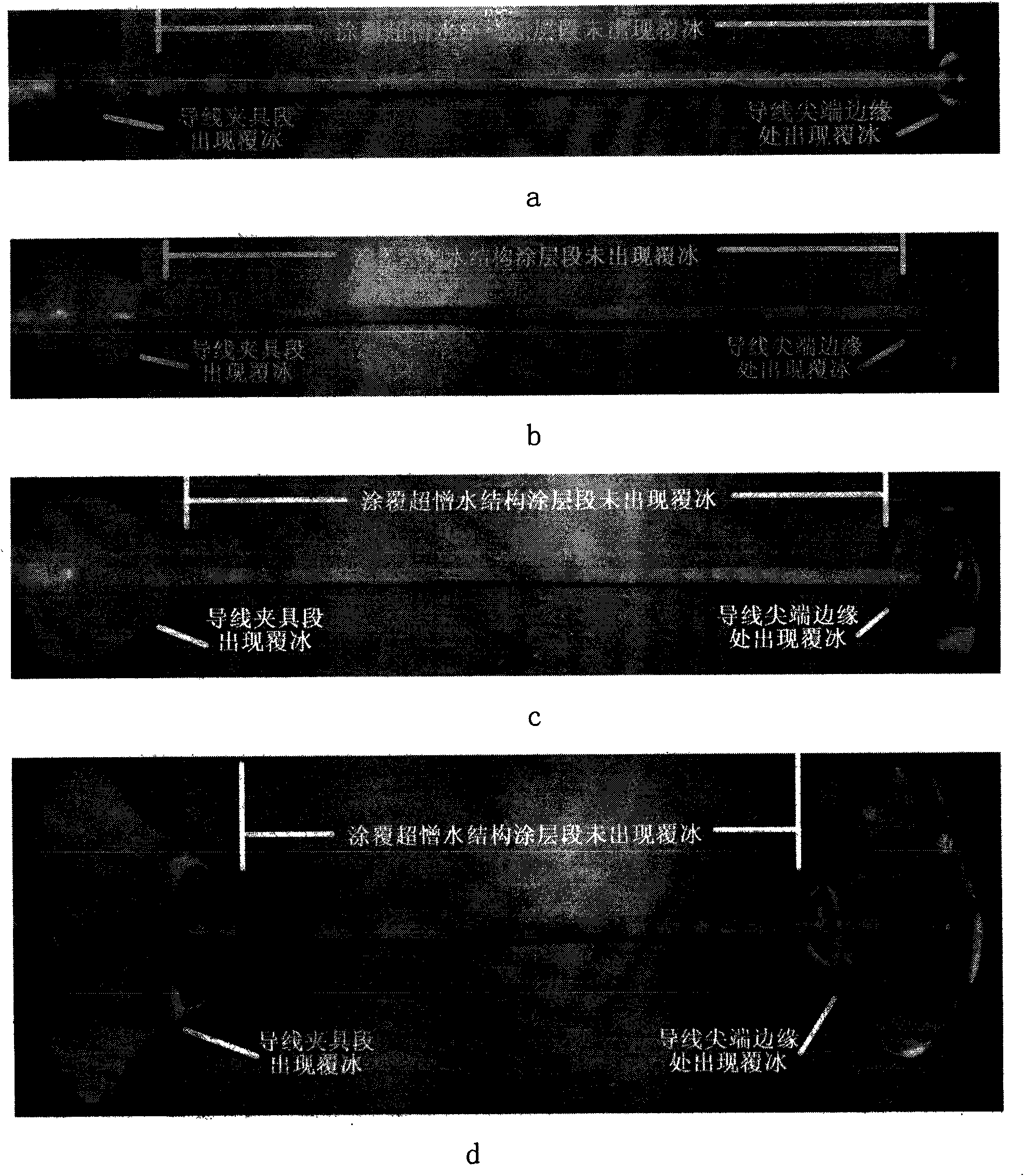

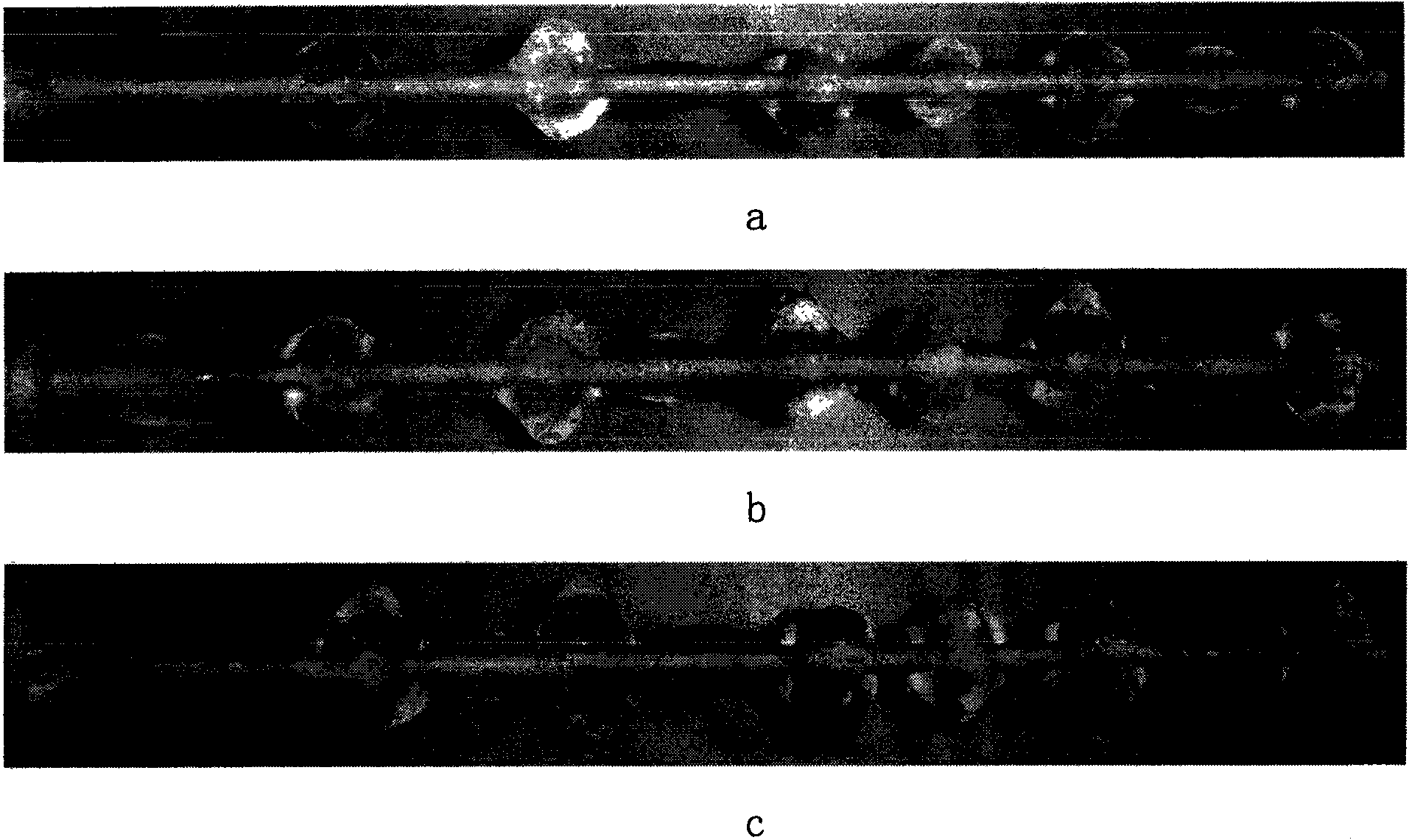

[0020] The above-mentioned aluminum wire rapidly treated with 25wt% mixed acid etchant, and the super-hydrophobic anti-icing aluminum wire modified with 2.5wt% fluorosilane solution low surface energy and the smooth aluminum wire without any treatment were treated at -6°C In the following low-temperature environment, supercooled water (water temperature 0°C) was used to carry out the water spray ice coating comparison test, and the surface was covered with ice to actually take pictures: The surface of the super-hydrophobic aluminum wire is coated with ice: as figure 1 a is spraying water for 10 minutes, figure 1 b means spraying water for 30 minutes, figure 1 c is spraying water for 60 minutes, figure 1 d is spraying water for 180 minutes; figure 2 Icing the surface of smooth aluminum wire without any treatment: such as figure 2 a is 10min, figure 2 b is 20min, figure 2 c is shown in 30min. It can be seen that the surface of the smooth aluminum wire without any treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com