Rotational structure of boiler rotary air heater

A technology of rotating structure and air heater, applied in lighting and heating equipment, combustion method, indirect carbon dioxide emission reduction, etc., can solve the problems of difficult realization, difficult rotation, complicated arrangement of steam supply pipes and drain pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

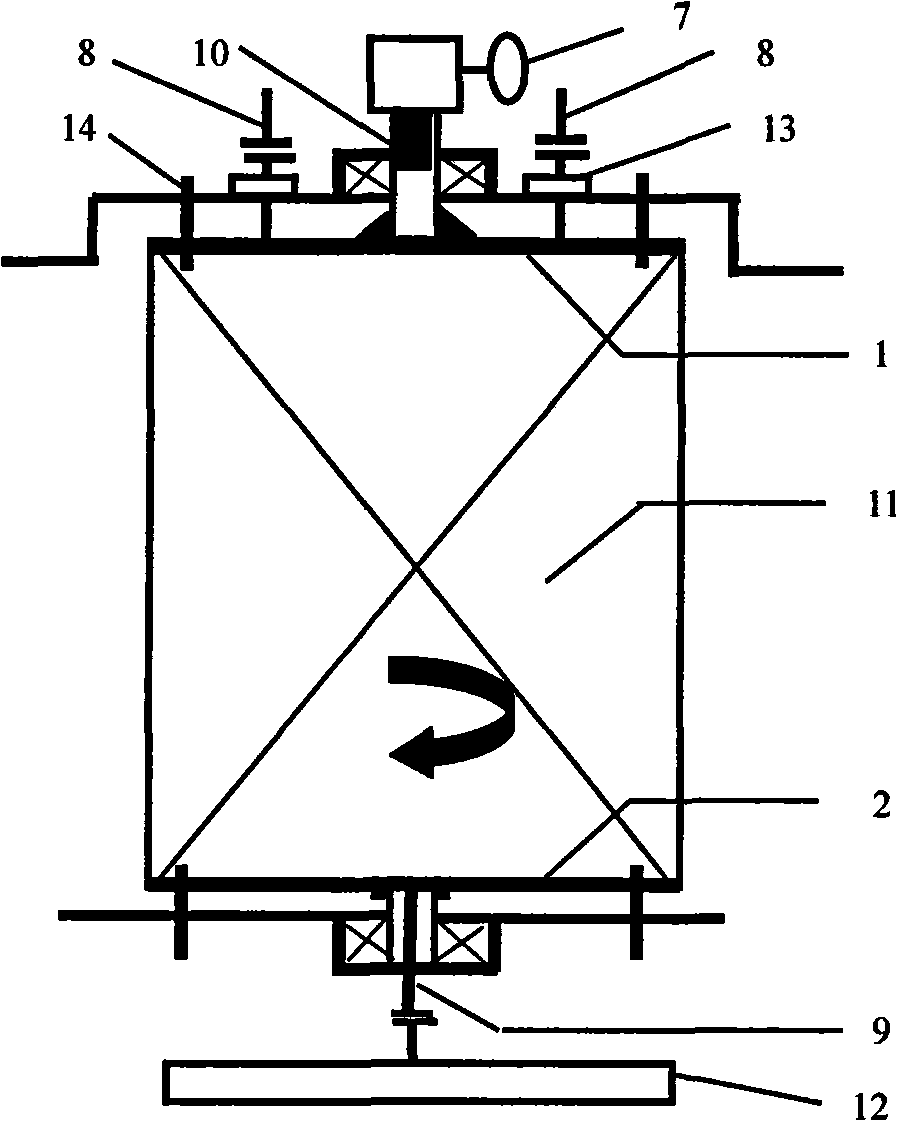

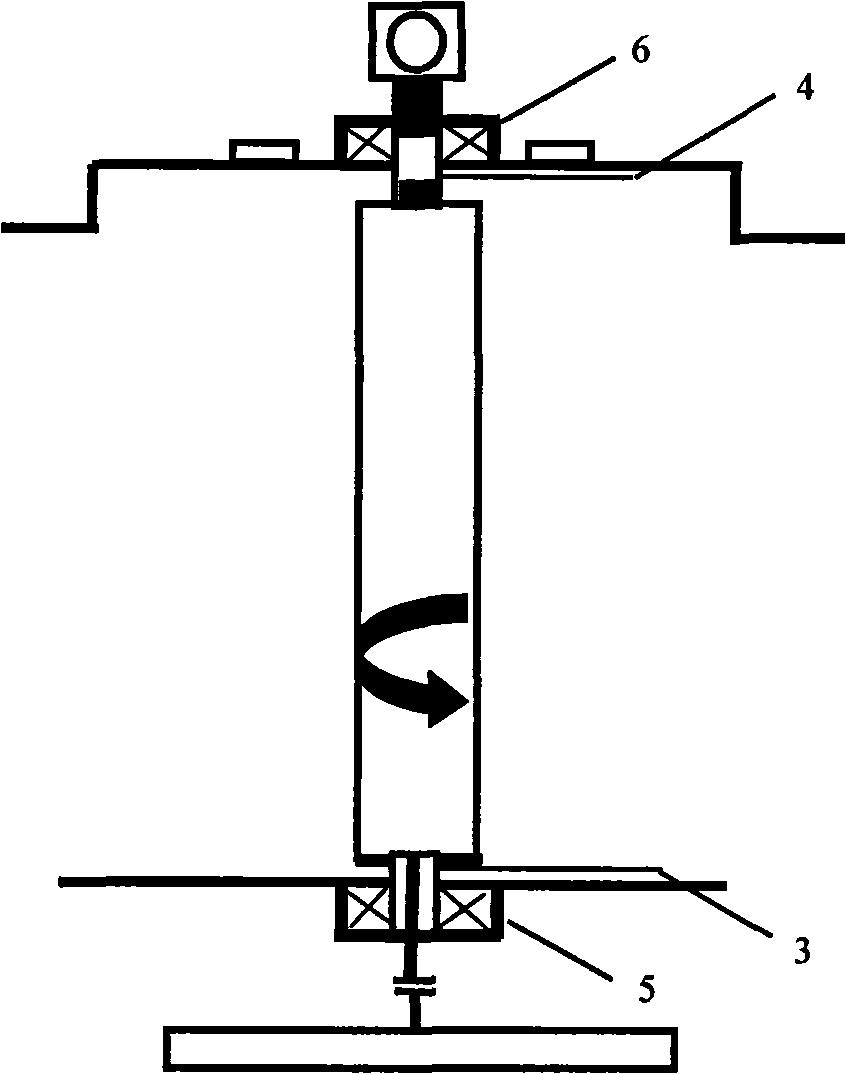

[0013] refer to figure 1 , figure 2 As shown, the two ends of the heat exchange surface are divided into a steam supply pipe 8 and a drain pipe 9. There are two steam supply pipes 8 on the steam supply side and one drain pipe 9 on the drain side. The drain pipe 9 on the drain side is located at the outlet header 2. In the middle position, the rotating shaft on the hydrophobic side is a round pipe (called "front rotating shaft 3"), and the drain pipe 9 passes through the front rotating shaft 3. One side of the front rotating shaft 3 is welded to the outlet header 2, and the other side is connected to the front bearing. 5 connection, which is an interference fit; on the steam supply side inlet header 1, select a position coaxial with the hydrophobic side rotation shaft to weld the rear shaft 4, and the other side of the rear shaft 4 is connected to the rear bearing 6, which is still an interference fit , the rear bearing 6 is connected with the actuator 7 through the solid sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com