Anti-corrosion technology for metal sheet hollow cavity of car body

A metal sheet and plate technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as perforation and corrosion resistance of automobile bodies, improve perforation corrosion resistance, reduce coating consumption, and reduce coating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] For the two car doors with the same coating process, the metal sheet used for one door is a cold-rolled sheet, and the metal sheet used for the other door is a galvanized sheet. After being placed in the open air in the seaside area of Qingdao, the corrosion situation appeared. obvious difference. It can be seen that there is no obvious difference between the two in the upper part of the outer surface of the car door, but in the lower part, due to the sandwich structure of the door panel, the cavity formed at the inner bottom cannot form a coating film of sufficient thickness in the electrophoretic coating. Therefore, the rust is from the inside to the outside until the rust wears through. At present, the protection of the inner surface of the car door generally adopts the method of wax injection, which increases the cost of wax injection materials, increases the equipment investment and manual operation costs of the wax injection process, and also increases the sel...

Embodiment 2

[0017] For two truck doors using the same metal sheet and the same painting process, because the opening positions and numbers of the inner door panels are different in structural design, the corrosion resistance effect after electrophoretic painting is obviously different. After the panel was cut open, there was no paint film attachment part, and yellow rust appeared on the surface, while the other door was completely coated with cathodic electrophoretic paint, and there was no rust after cutting. Therefore, optimizing the structural design of automobile products to make the paint film of each part complete is also one of the effective ways to improve the anti-corrosion performance of the whole vehicle.

Embodiment 3

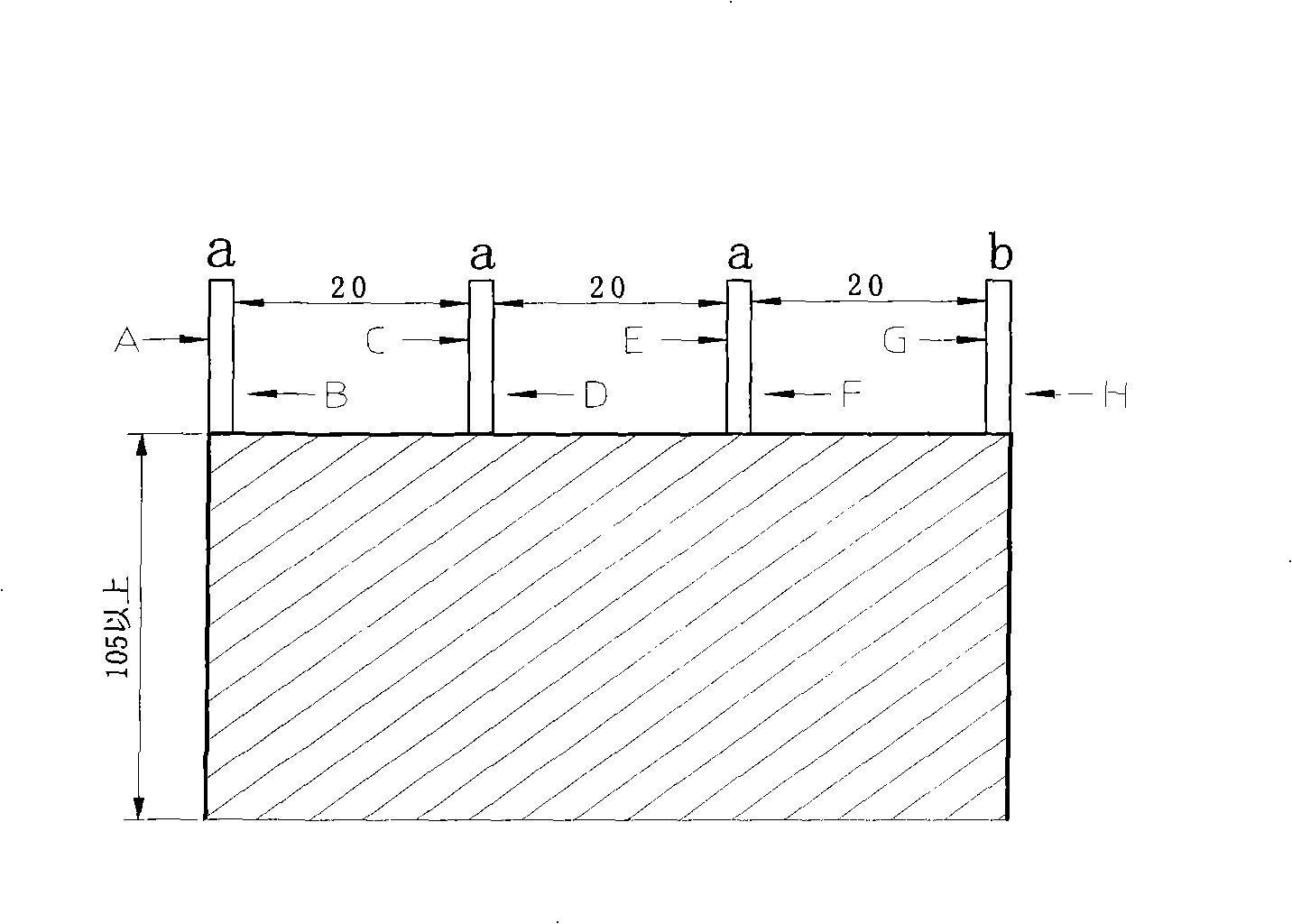

[0019] During the electrophoretic coating process, under the action of an electric field, the ability of the electrophoretic paint to coat the part of the object to be coated away from the corresponding electrode, that is, the ability to paint on the weld and inner cavity of the coated workpiece, is called electrophoretic paint. penetration. At present, the 4-box method (4-box method) is generally used to evaluate the throwing power of cathodic electrophoretic coatings, which is closer to simulating the actual throwing performance of the interior of the car body than the steel pipe method and the volt box method. In this method, the film thickness of each part of the four boxes is used as the evaluation object, and the four test boards are arranged vertically, and the order is as follows: figure 1 shown. The distance between the boards is 20mm, and the painted surfaces of the test boards are recorded in order from left to right: A-side / B-side-C / D-side-E-side / F-side-G-side / H-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com