Optical anode used for hydrogen production by photoelectrochemistry decomposition water and preparation method thereof

A photoelectrochemical and water splitting technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low electrocatalytic activity and narrow bandwidth, and achieve the effects of high electrocatalytic activity, energy saving, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

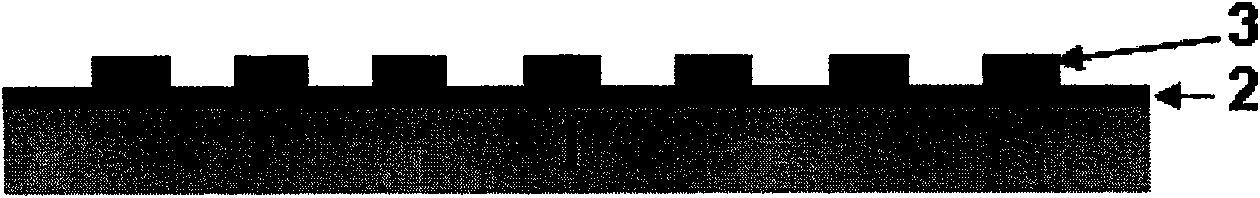

[0054] Put the ITO with a side length of 2 cm in the container, wash it with detergent powder in turn, wash it with acetone, ethanol, and deionized water by ultrasonic vibration, and then put it in a drying oven (Tianjin Test, 101-1AB) at 60 ° C dried to obtain figure 1 The conductive glass shown in 1. Then, place the conductive glass in the chamber of a sputtering coating instrument (MSP-300, Genesis Wiener), install the W target on the radio frequency back target, and simultaneously feed the mixed gas of oxygen and argon into the chamber (Oxygen accounts for 40% by volume), then turn on the power supply and start coating, and turn off the power supply after 2 hours to stop coating, and obtain such as figure 2 Conductive glass with sputtered layer 2 after sputtering shown in . Afterwards, a screen mesh with a square mesh and a side length of 4 microns was pasted on the film, and the power was turned on to continue coating. After 2 hours, turn off the power, stop the coati...

Embodiment 2

[0057] Put FTO with a side length of 2 cm in a container, wash it with detergent powder, acetone, ethanol, and deionized water with ultrasonic vibration, and then dry it in a drying oven (Tianjin Test, 101-1AB) at 60 ° C. dried to obtain figure 1 The conductive glass shown in 1. Then, the conductive glass was placed in the cavity of a sputtering coating instrument (MSP-300, Genesis Weina), the Ti target was installed on the radio frequency back target, and a mixed gas of oxygen and argon was introduced into the cavity at the same time (Oxygen accounts for 30 volume %), then turn on the power supply and start coating, turn off the power supply after 1.5 hours and stop coating, obtain such as figure 2 Conductive glass with sputtered layer 2 after sputtering shown in . Afterwards, a screen mesh with a square mesh and a side length of 3 microns was pasted on the film, and the power was turned on to continue coating. After 1.5 hours, turn off the power, stop the coating, and ge...

Embodiment 3

[0060] Except Ni(NO in the ethanol solution in embodiment 1 3 ) 3 ·6H 2 O (Tianjin Huadong Reagent Factory) and Fe (NO 3 ) 3 9H 2 Except that the quality of O (Tianjin Huadong Reagent Factory) was changed to 4.66 grams and 6.46 grams respectively, the photoanode for splitting water to produce hydrogen was prepared according to the conditions described in Example 1.

[0061] According to the above measurement method, in the prepared photoanode for splitting water to produce hydrogen, the thickness of the sputtered layer is 1.5 microns; the height of the protrusions is 1.5 microns, the diameter is 4 microns, and the density is 6.3×10 6 piece / cm 2 ; and the Ni-Fe oxide film thickness is 110 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com