Method for preparing silica gel supported titanium-magnesium catalyst

A technology of catalyst and silica gel, which is applied in the field of preparation of high-activity silica gel-supported titanium-magnesium catalysts, which can solve the problems of increased specific surface area, reduced performance, and reduced pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

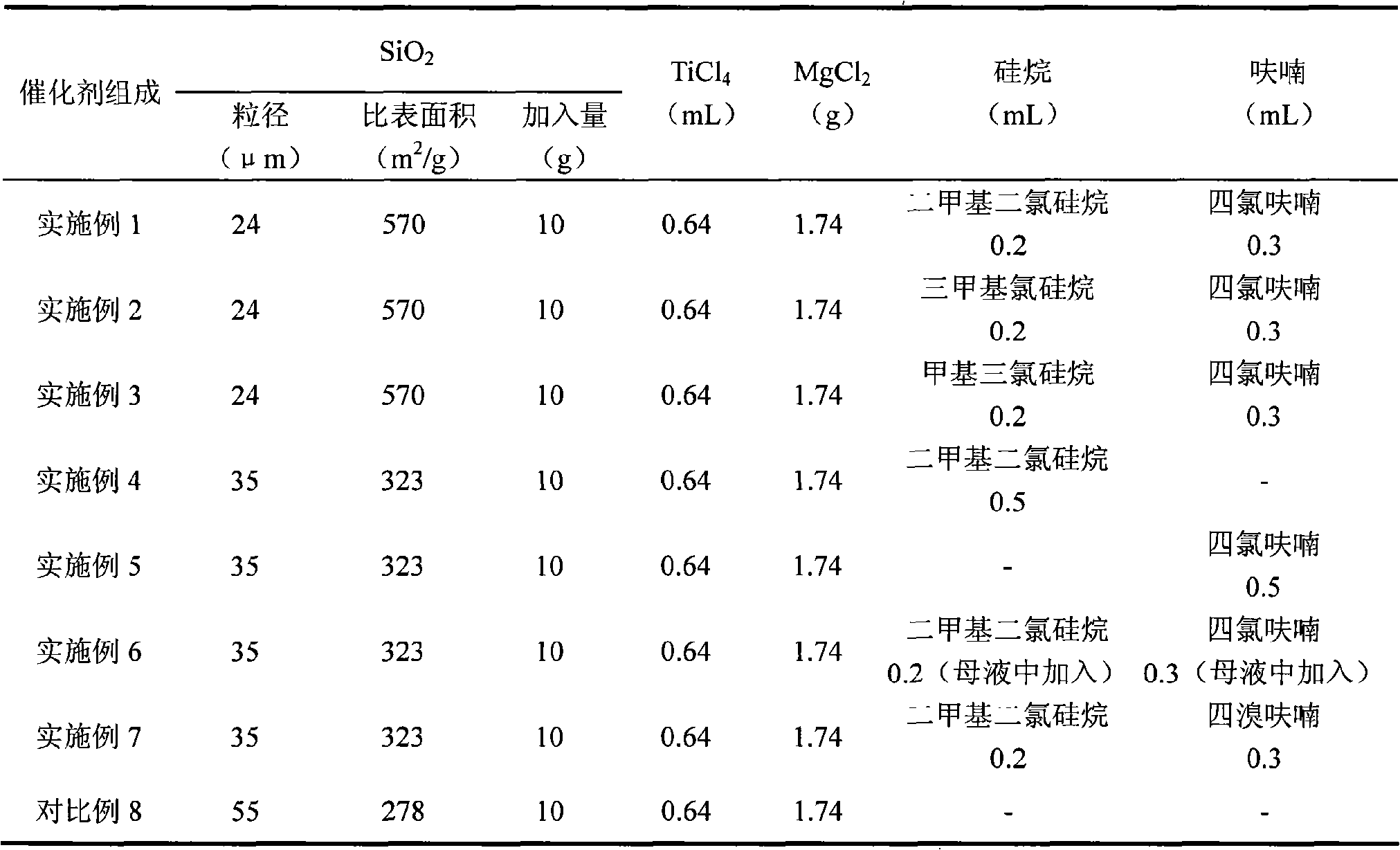

[0018] Preparation of catalyst components

[0019] (1) Weigh about 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 24μm and a specific surface area of 570m 2 / g), activated in a gas-phase fluidized bed activator at 600°C for 4 hours.

[0020] (2) In a reaction flask with a stirrer under nitrogen protection, add 100 mL of isopentane, 10 g of silica gel after thermal activation treatment in step (1) and 5.6 mL of AlEt with a concentration of 1 mmol / mL 3 Add the hexane solution, react at 20-30°C for half an hour, then slowly add 0.2mL dimethyldichlorosilane and 0.3mL tetrachlorofuran dropwise, and react for half an hour after the addition, then purge and dry it with high-purity nitrogen to become a fluid sexual powder.

[0021] (3) In another reaction flask with a stirrer, add 1.74g MgCl 2 and 0.64mL TiCl 4 and 174mL of tetrahydrofuran, heated and refluxed and stirred for 5 hours to obtain the catalyst mother liq...

Embodiment 2

[0028] Preparation of catalyst components

[0029] (1) Weigh about 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 24μm and a specific surface area of 570m 2 / g), activated at 600°C for 4 hours in a gas-phase fluidized bed activator.

[0030] (2) In a reaction flask with a stirrer under nitrogen protection, add 100 mL of isopentane, 10 g of silica gel after thermal activation treatment in step (1) and 5.6 mL of AlEt with a concentration of 1 mmol / mL 3 Add the hexane solution, react at 20-30°C for half an hour, then slowly add 0.2 mL of trimethylchlorosilane and 0.3 mL of tetrachlorofuran, blow and dry with high-purity nitrogen to form a fluid powder.

[0031] (3) In another reaction flask with a stirrer, add 1.74g MgCl 2 and 0.64mL TiCl 4 and 174mL of tetrahydrofuran, heated and refluxed and stirred for 5 hours to obtain the catalyst mother liquor.

[0032] (4) Mix the modified silica gel in step (2) with the ...

Embodiment 3

[0038] Preparation of catalyst components

[0039] (1) Weigh about 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 24μm and a specific surface area of 570m 2 / g), activated in a gas-phase fluidized bed activator at 600°C for 4 hours.

[0040] (2) In a reaction flask with a stirrer under nitrogen protection, add 100 mL of isopentane, 10 g of silica gel after thermal activation treatment in step (1) and 5.6 mL of AlEt with a concentration of 1 mmol / mL 3 Add the hexane solution, react at 20-30°C for half an hour, then slowly add 0.2mL methyltrichlorosilane and 0.3mL tetrachlorofuran dropwise, react for half an hour after the addition, and purge and dry with high-purity nitrogen to become fluid powder.

[0041] (3) In another reaction flask with a stirrer, add 1.74g MgCl 2 and 0.64mL TiCl 4 and 174mL of tetrahydrofuran, heated and refluxed and stirred for 5 hours to obtain the catalyst mother liquor.

[0042] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com