Tubular membrane element and integral membrane bioreactor

A technology of tubular membranes and membrane elements, which is applied in the field of membrane bioreactors and membrane elements, which can solve the problems of easy fiber breakage, increased cleaning difficulty, and fiber breakage, so as to achieve not easy to break, reduce the probability of breakage, and easy to clean Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

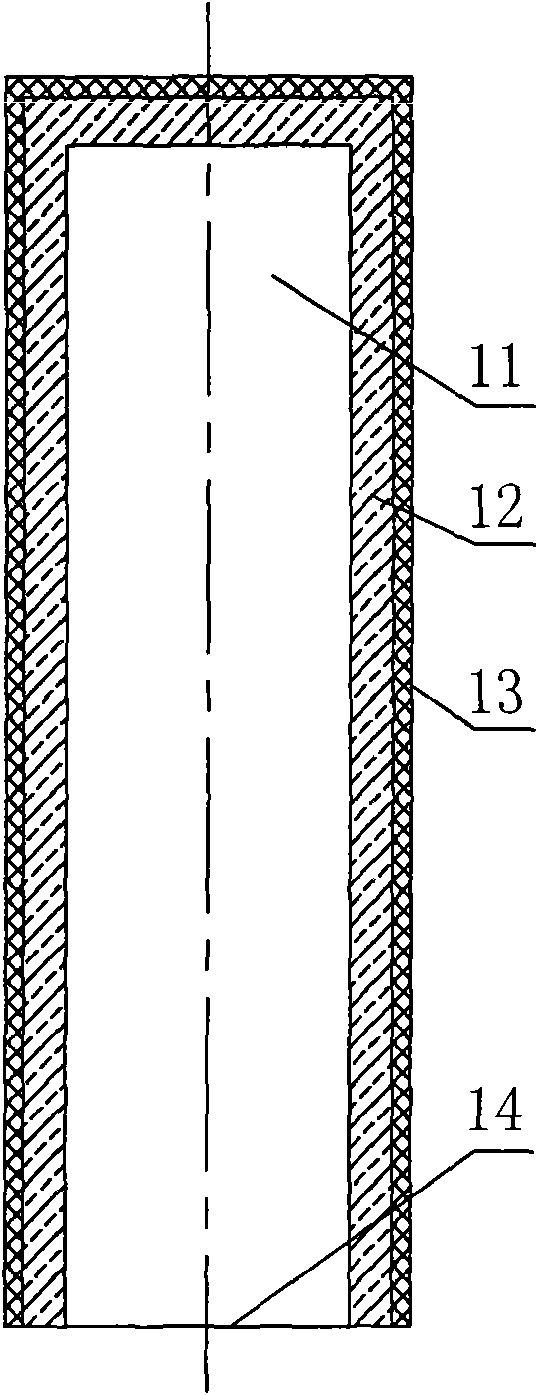

[0028] Such as figure 1 , figure 2 As shown, a tubular membrane element of the present invention includes an inner cavity 11 and a cylindrical support layer 12 , and the outer surface of the support layer 12 is covered with an organic filter membrane layer 13 . Wherein, the organic filtration membrane layer 13 can be a microfiltration membrane with a surface pore size of 0.1 micron, or an ultrafiltration membrane with a surface pore size of 0.01 micron, which is formed by a polymer material coating, and the material of the membrane coating can be poly Ethersulfone, polysulfone, polyvinylidene fluoride, etc. The support layer 12 is permeable to allow water to enter the inner cavity through the organic filter layer. The support layer 12 is made of reinforced porous organic material, such as porous high-density polyester material. Due to the existence of the support layer, the tubular membrane element can have a thicker diameter. For example, the inner cavity 11 can be designe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com