Proton exchange membrane fuel cell metal bipolar plate

A metal bipolar plate and proton exchange membrane technology, which is applied to fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of manufacturing difficulties and high precision requirements of unipolar plates, achieve low processing costs, and meet the needs of battery replacement. Heat demand, good distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

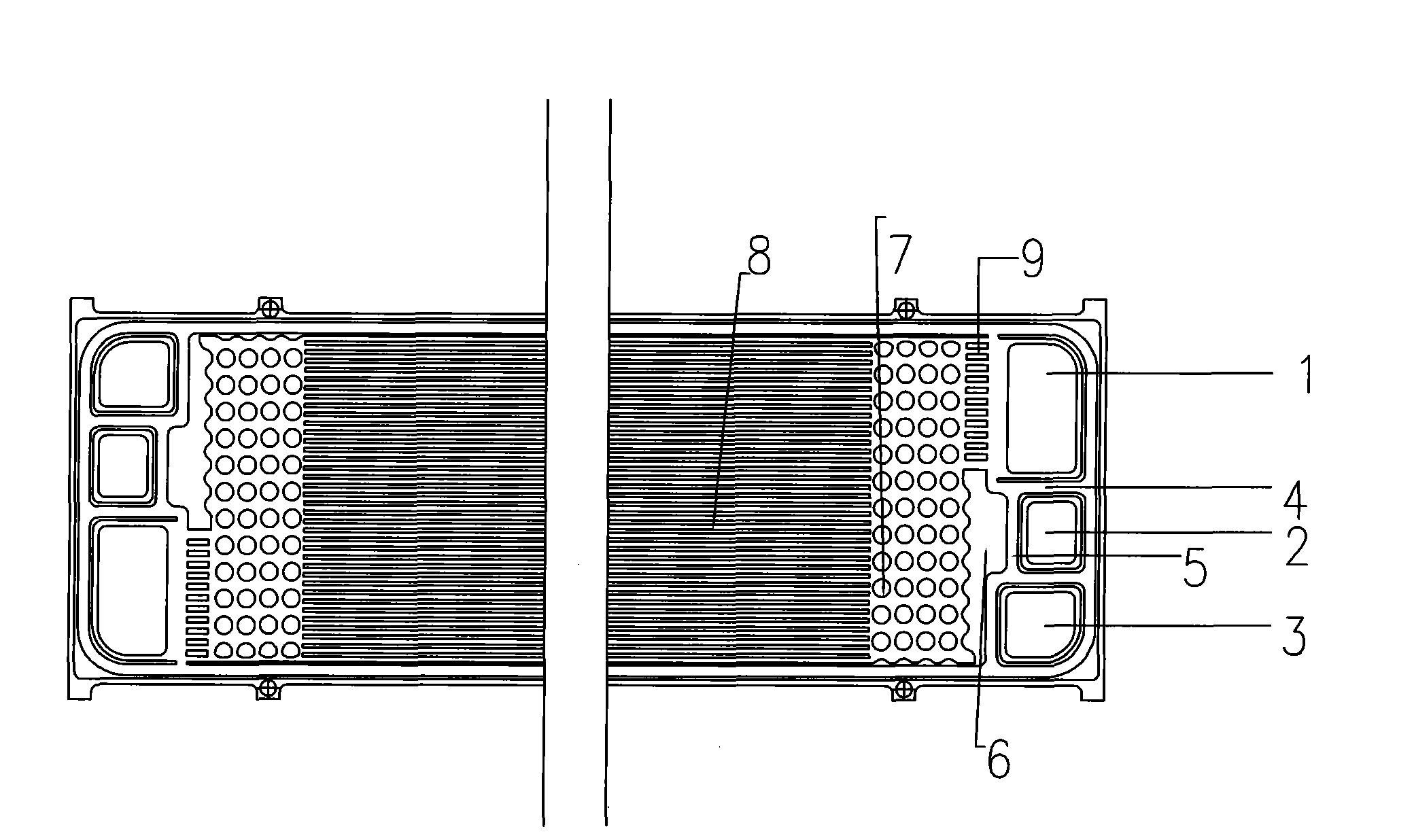

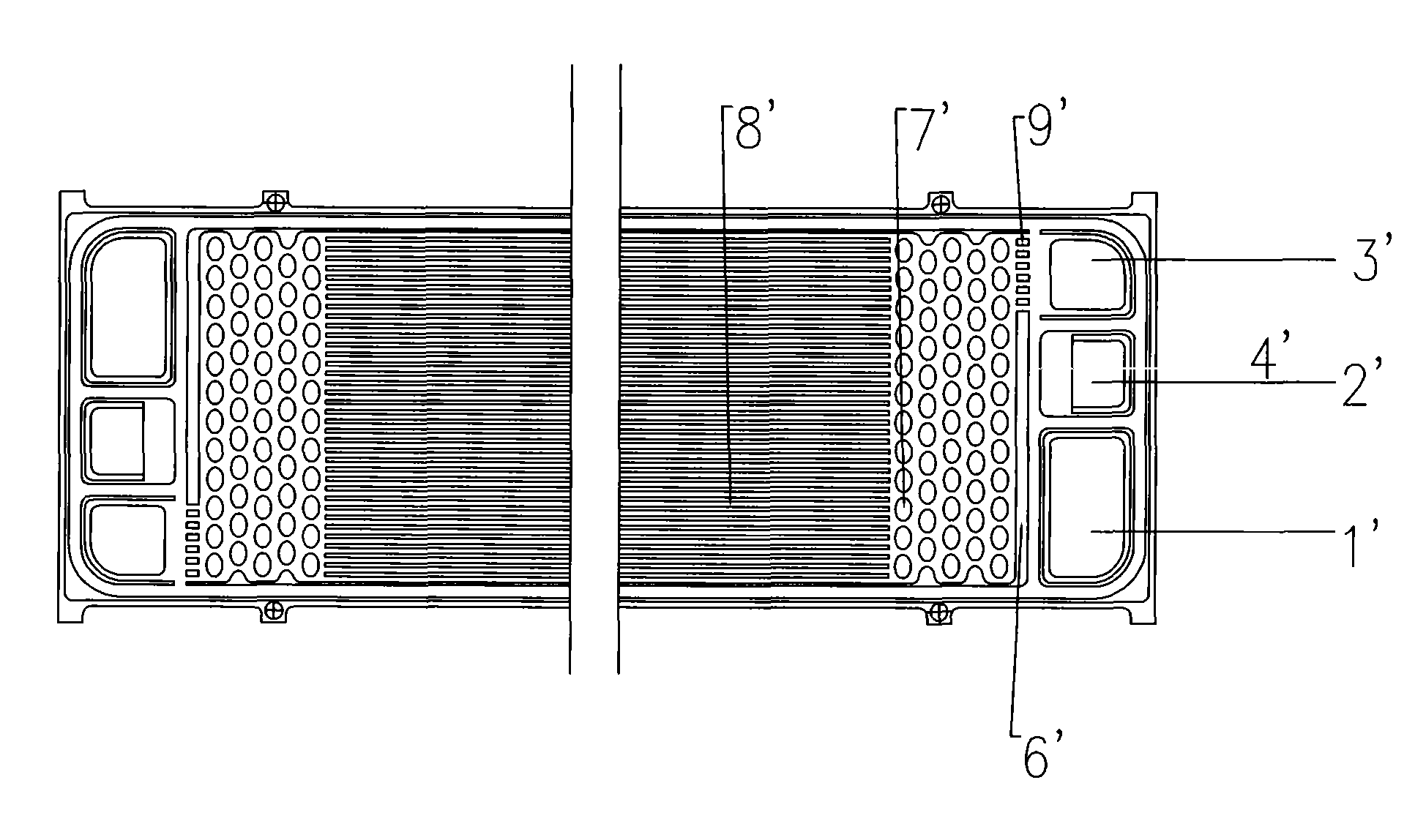

[0020] attached Figure 1~5 It is the accompanying drawing of Embodiment 1. The overall size of the bipolar plate is 410x100mm, the effective area of the flow field part is 340x85mm, and the rest is a sealed structure. The plate material is a 0.1mm stainless steel sheet, and the cathode and anode plates are punched by cold stamping technology, and bonded to form a bipolar plate. The thickness of the bipolar plate is 1.2mm, and the depth of the flow field is 0.5mm.

[0021] The dotted flow field bosses in the distribution section of the anode plate are elliptical bosses with a long diameter of 5.8mm and a short diameter of 4.0mm. The center position is at the midpoint of the line connecting the center positions of the two bosses in the front row. The point-like flow field boss of the cathode plate distribution section is an elliptical boss with a long diameter of 4.8mm and a short diameter of 4.6mm. The flow field of the point-shaped boss of the cathode plate is convex. The...

Embodiment 2

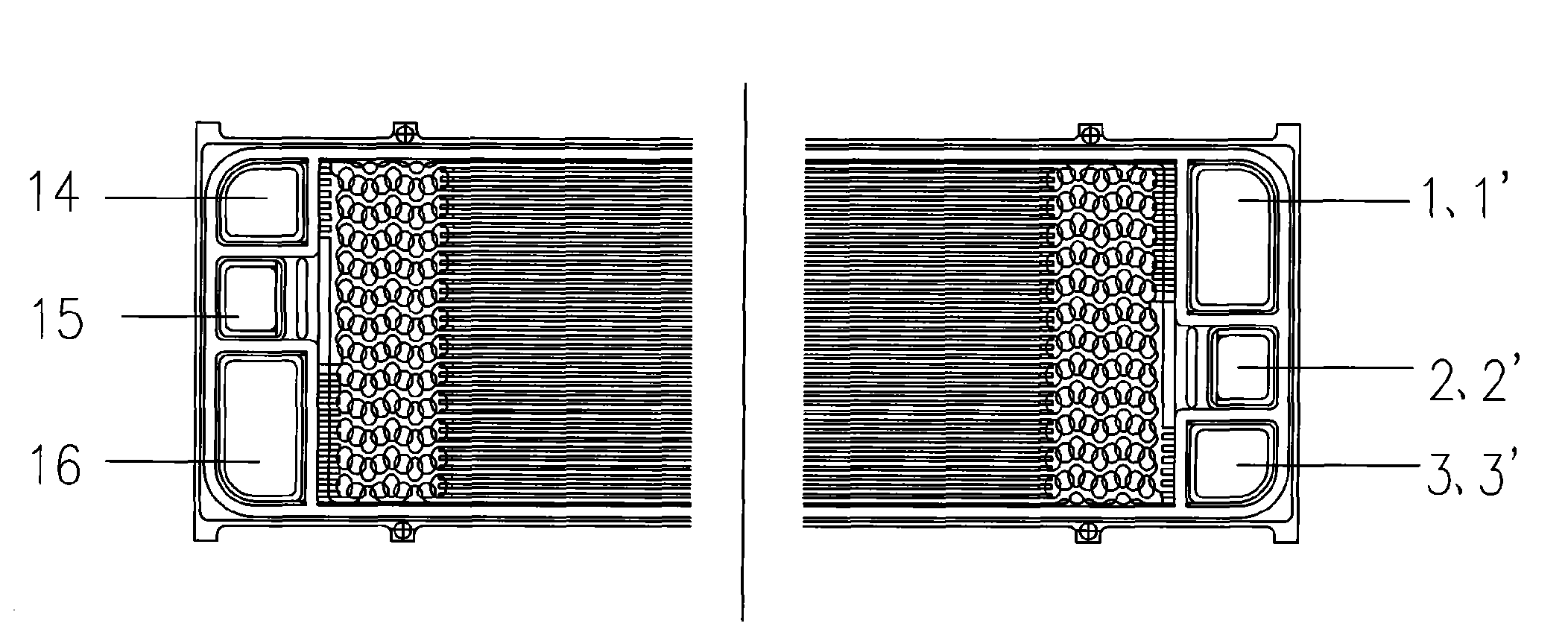

[0028] attached Figure 6-8 It is the accompanying drawing of Embodiment 1. The specification and shape of the bipolar plate are the same as in Example 1.

[0029]The point-shaped flow field bosses of the distribution section of the anode plate are elliptical bosses with a long diameter of 5.8mm and a short diameter of 4.0mm. The dot-shaped flow field bosses are elliptical bosses with a long diameter of 4.8mm and a short diameter of 4.6mm. The dot-shaped bosses of the cathode plate are arranged in a parallel and regular arrangement, that is, there are 3 rows of bosses, and the distance between the bosses is 2mm, the pits on the back of the convex plate of the cathode and anode plates are connected in series, the overlapping area is about 1 / 7 of the ellipse with a long diameter of 4.8mm and a short diameter of 4.6mm, the length of the distribution section of the anode plate is 28mm, and the length of the distribution section of the cathode plate is 22mm , the length of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com