Microcoulomb analysis method for chlorinity high-temperature burning of organic phosphate fire-resistant oil and device thereof

A high-temperature combustion and analysis method technology, applied in the fields of electrochemical variables of materials, special data processing applications, instruments, etc., can solve the problems of difficult test conditions, complicated operation steps, long time-consuming, etc., to avoid toxic chemical reagents, and to achieve accurate manual measurement. , The effect of good test reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

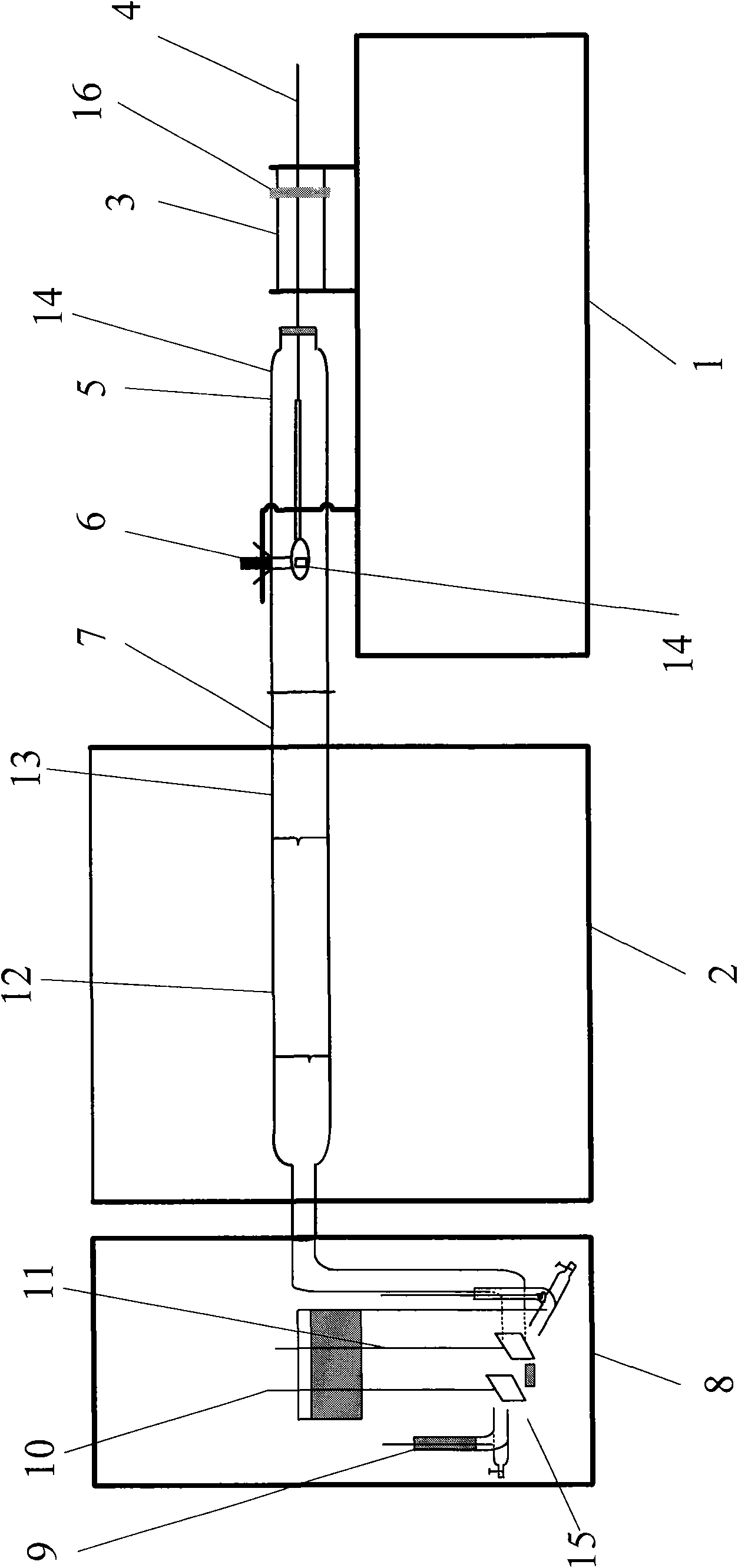

[0023] Such as figure 1 The high-temperature combustion microcoulomb analysis device for phosphate-resistant fuel oil chlorine content shown is mainly composed of three parts: a high-temperature furnace 2, a sampler 1 and an electrolytic cell 15. The combustion tube 14 is inserted in the high-temperature furnace, including the gasification section 13 and the combustion chamber. Section 12 has an oxygen port 7, a nitrogen port 5 and a sample inlet 6 on it. The sample injector includes a support, a slide rail 3 arranged on the support and a slide block 16 matched with the slide rail. The slide block 16 is fixedly connected to the pull rod 4, and one end of the pull rod 4 extends into the combustion tube 14 and is connected with a sample boat. 14. The electrolytic cell is generally arranged in a shielding box 8, which includes a pair of electrolytic electrodes 11, a reference electrode 9 and a measuring electrode 10, which cooperate to control the electrolytic process.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com