Tool holder for a rotating tool and method for clamping a rotating tool in tool holder

A technology for rotating tools and tool holders, which is applied in the field of tool holders and for clamping rotating tools in tool holders, and can solve problems such as limiting the feed speed of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

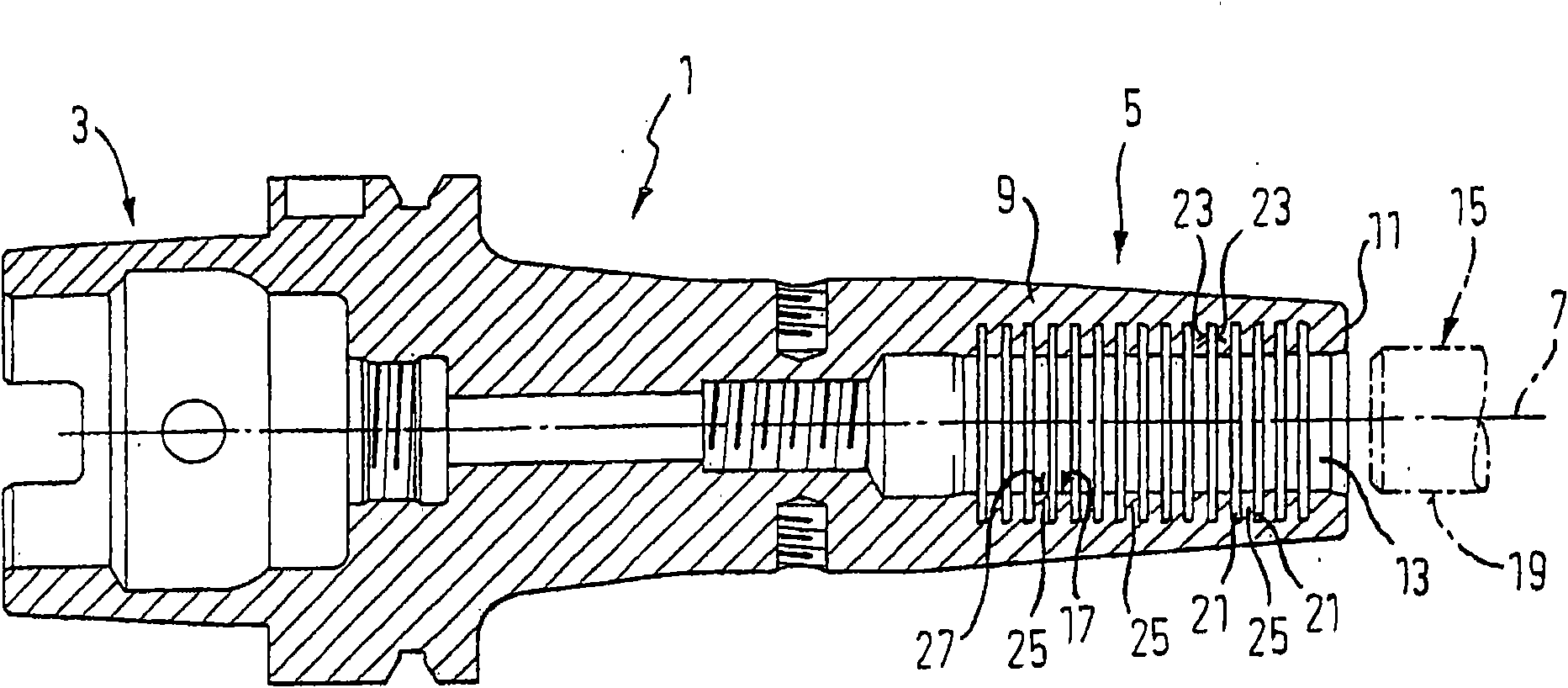

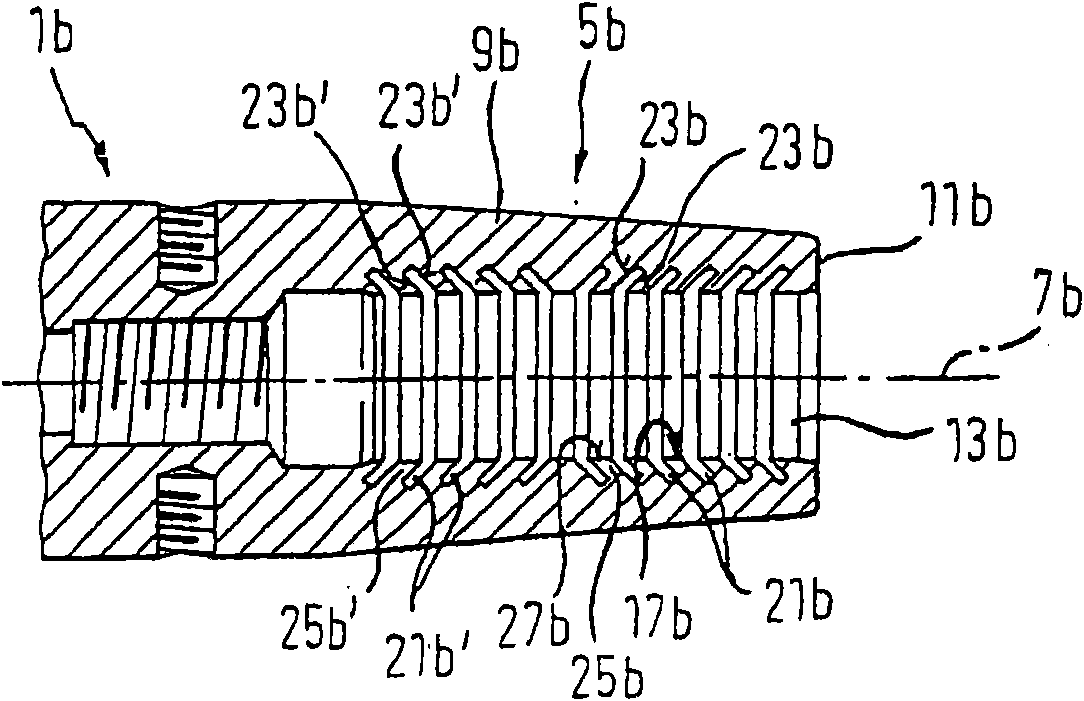

[0042] figure 1 A tool holder 1 of the shrink chuck type is shown, comprising an engagement portion 3, here in the form of a hollow shank taper (HSK), for rotationally fixed engagement with a working spindle of a machine tool at its axial end ; and a clamping portion 5 at the other axial end thereof. The axis of rotation of the tool holder 1 is indicated with 7 . The engagement portion 3 can have any shape, ie also in the form of a steep taper or the like. The clamping part 5 has the basic shape of a housing 9 , which terminates in an end face 11 extending perpendicular to the axis of rotation 7 and comprises a cylindrical receiving opening 13 concentric to the axis of rotation 7 , a rotary tool not shown in detail, A cylindrical tool shank 15 , for example a milling cutter or a drilling tool, is inserted exchangeably into the receiving bore as will be described in more detail later. for clarity figure 1 The tool shank 15 is shown prior to insertion into the receiving hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com