Method of embedding opto-electronic components in layer

A technology of optoelectronic devices and embedded layers, which is applied in the direction of electric solid devices, household components, electrical components, etc., can solve the problems of device damage, device overmolding, etc., and achieve the effect of reducing the risk of damage to the device and reducing the extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

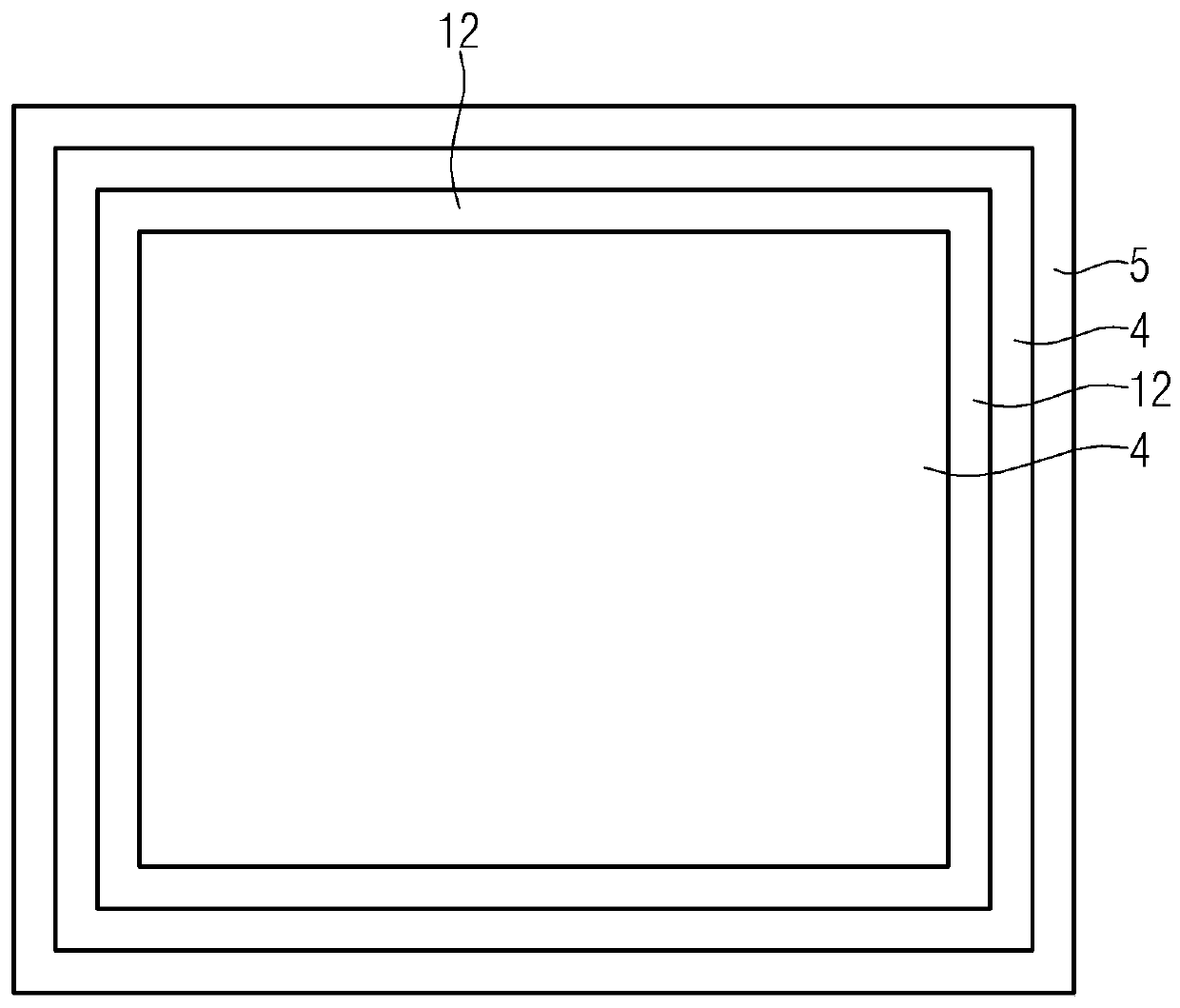

[0034] figure 1 A schematic sectional view through the device for embedding an optoelectronic component 1 in a layer is shown. A forming tool 2 is provided which, in the exemplary embodiment shown, has a cover plate 3 and a carrier plate 4 . Furthermore, a film 5 is arranged on the underside of the carrier plate 4 . The film 5 here covers the entire underside of the carrier plate 4 and is thus arranged between the carrier plate 4 and the component 1 . Depending on the chosen embodiment, the membrane 5 can be dispensed with. The optoelectronic component 1 is designed, for example, as a radiation component. For example, the optoelectronic component 1 can be designed in the form of a light-emitting diode. The component 1 is arranged on a carrier 6 . In the exemplary embodiment shown, the carrier plate 4 is made of elastic material. For example, the carrier plate 4 can be made of spring steel. The carrier plate 4 has an underside 7 which is substantially flat under no load....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com