Method for preparing magnetic nano composite particles of FeCr alloy dispersed in ceramic crystal grain

A technology of ceramic crystal grains and magnetic nanometers, which is applied in the field of preparation of inorganic magnetic nanocomposite particles, can solve the problems of difficult control of particle size distribution and monodispersity, loss of special magnetic properties, easy aggregation of nanoparticles, etc., and achieve thermal stability Improvement, stability improvement, and guaranteed effect of nanostructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

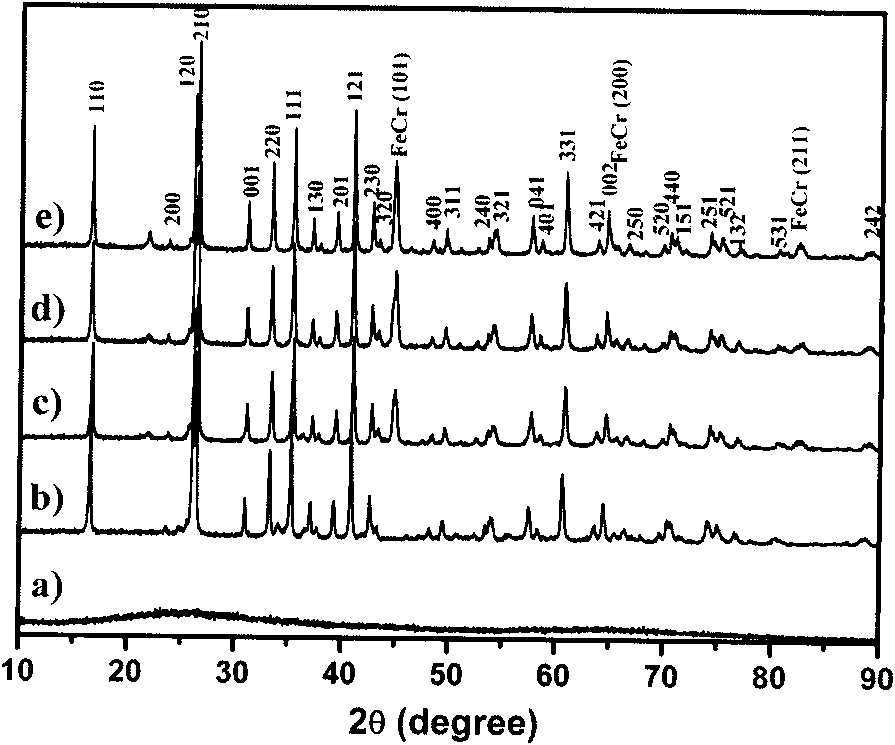

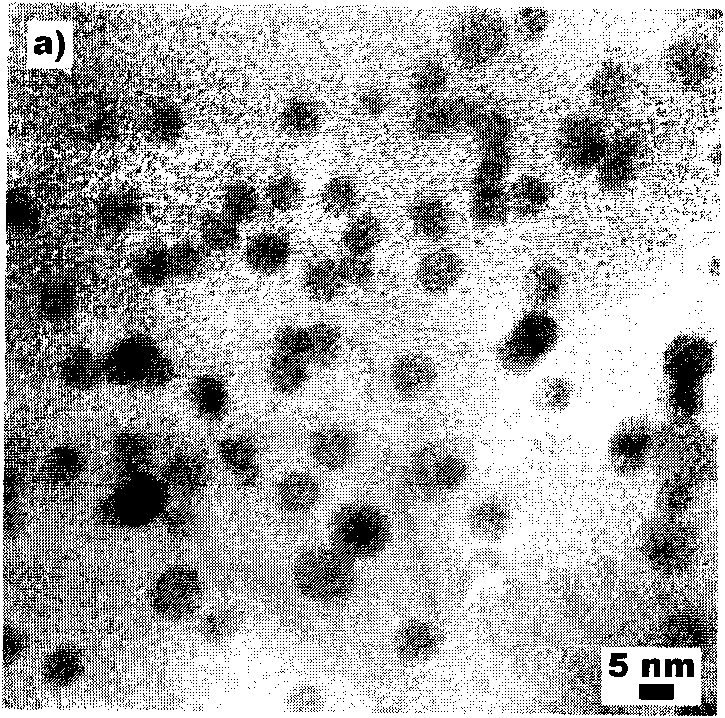

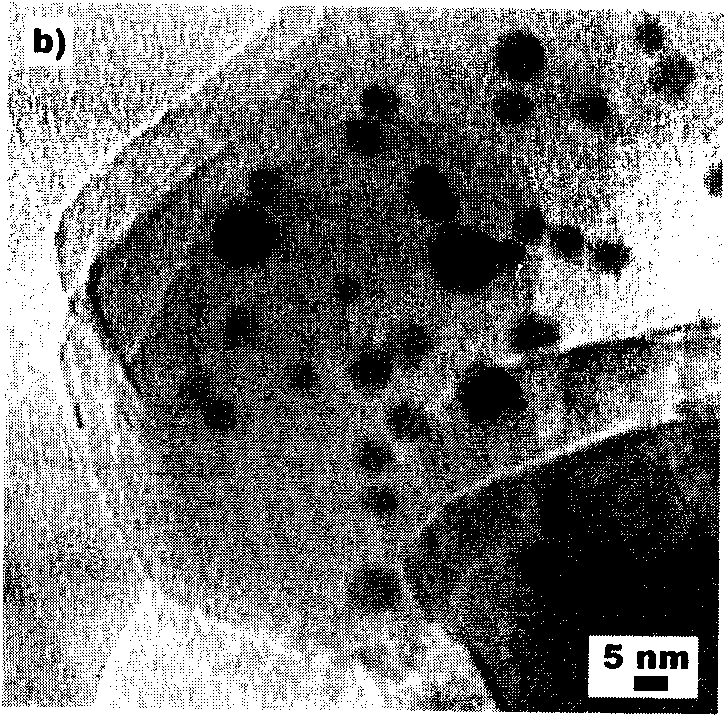

[0032] According to the chemical formula Al 5.4 Fe 0.36 Cr 0.24 Si 2 o 13 , 0.54mol Al(NO 3 ) 3 9H 2 O, 0.036mol Fe(NO 3 ) 3 9H 2 O and 0.024mol Cr(NO 3 ) 3 9H 2 O was dissolved in 400ml of absolute ethanol to form a solution with a sum of molar concentrations of metal ions of 1.5mol / L, heated in a water bath to 60°C and vigorously stirred by magnetic force; after the solution was stirred for 6 hours, HNO with a molar concentration of 1.5mol / L was added dropwise 3 Solution, adjust the pH value of the solution to 3 and continue to stir for 3 hours; add 0.2mol tetraethyl orthosilicate (TEOS) dropwise to the solution, and add NH with a molar concentration of 15mol / L dropwise 3 ·H 2 O to adjust the pH value of the solution to 5, continue to stir for 5 hours, and then move the sol to a constant temperature water bath at 80°C for aging until a xerogel (or precursor) is formed. The xerogel was calcined at 500 °C for 5 h in flowing air to obtain amorphous oxide powder (i...

Embodiment 2

[0036] According to the chemical formula Al 5.4 (Fe 1-x Cr x ) 0.6 Si 2 o 13 , (x=0.1~0.5), with Al(NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 O, Cr(NO 3 ) 3 ·9 H 2O and tetraethyl orthosilicate (TEOS) are carried out proportioning as raw material, according to the technique of embodiment 1, obtain and form Fe 3+ and Cr 3+ Mullite solid solution ceramic powder with complete solid solution of ions; Fe 3+ and Cr 3+ H 2 The gas was reduced at 1200°C for 1 hour, and the obtained products were magnetic nanocomposite particles of FeCr alloy dispersed in ceramic grains of different compositions. It can be affected by the composition of Fe and Cr in solid solution.

Embodiment 3

[0038] According to the chemical formula Al 5.9 Fe 0.09 Cr 0.01 Si 2 o 13 , 0.59mol Al(NO 3 ) 3 9H 2 O, 0.009mol Fe(NO 3 ) 3 9H 2 O and 0.001mol CrCl 3 9H 2 O was dissolved in 600ml of absolute ethanol to form a solution with the sum of the molar concentrations of metal ions being 1mol / L, heated in a water bath to 90°C and strongly magnetically stirred; after the solution was stirred for 1 hour, HNO with a molar concentration of 1mol / L was added dropwise 3 Solution, adjust the pH value of the solution to 3.5 and continue to stir for 3h; add 0.2mol tetraethyl orthosilicate (TEOS) dropwise to the solution, and add NH with a molar concentration of 13mol / L dropwise 3 ·H 2 O to adjust the pH value of the solution to 5.5, continue to stir for 5 hours, and then move the sol to a constant temperature water bath at 60°C for aging until a xerogel (or precursor) is formed. The xerogel was calcined at 400 °C for 5 h in flowing air to obtain amorphous oxide powder (ie precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com