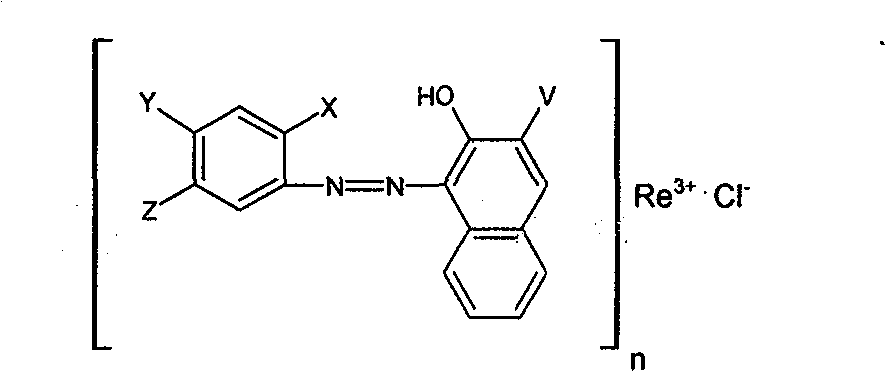

Rare earth complex red pigment with excellent pigment performance and application thereof

A red pigment and rare earth technology, applied in the field of monoazo rare earth complexed red pigments, can solve the problems of heat resistance stability, poor light fastness, etc., and achieve excellent migration resistance, simple synthesis process, and cheap and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021]

[0022] Dissolve CLT acid (0.021mol, 4.87g) and 6.24ml of 5N dilute hydrochloric acid in 130ml of water, slowly add 2.88ml of 52.6% sodium nitrite solution, and keep the temperature at 15-18°C. After 3 h of reaction a diazotized suspension was obtained. Excess sodium nitrite was removed by adding sulfamic acid, and starch-potassium iodide test paper was used to check whether excess sodium nitrite was removed.

[0023] Mix 3.52ml of 45% NaOH solution with 40ml of water, dissolve in β-naphthol (0.022mol, 3.26g) and dilute to 90ml. Add the diazotized suspension at 20°C and, after stirring well, neutralize with acetic acid solution (0.5 g glacial acetic acid dissolved in 3 ml water). Then fully stir, filter, and dry at 60°C to obtain the early stage dye.

[0024] The obtained early stage dye was purified by recrystallization from DMF, dissolved in 40ml of water, and stirred for 12h. Then heat to above 100°C to obtain a transparent solution, then add 70ml of acetic ac...

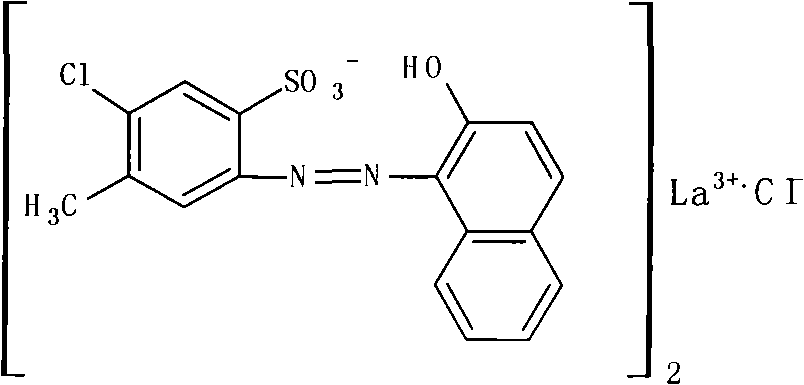

Embodiment 2

[0027]

[0028] Dissolve 4B acid (0.026mol, 5g) in water, and then add 6g of 25% ammonia solution to adjust the pH to ≥8. After stirring until the solution is completely clear, add an ice bath and cool down to 0°C. Join NaNO 2 1.93g, then slowly add 12.5g of 20% dilute hydrochloric acid dropwise, t=0-5°C, and reach the end of diazotization after half an hour. Excess sodium nitrite was removed by adding sulfamic acid, and starch-potassium iodide test paper was used to check whether excess sodium nitrite was removed.

[0029] 6.265gNa 2 CO 3 The prepared 4% alkali solution dissolved 2,3-acid (0.027mol, 5.24g), pH>8. Add it dropwise to the above diazonium solution within 20min at a temperature of 8-10°C. After the addition, adjust the pH to 10-10.2. It reaches the end point after 2 hours. Filter, wash with water, and dry at 60°C to obtain the early stage dye.

[0030] The obtained early stage dye is purified by acetic acid recrystallization, dissolved in an appropriate ...

Embodiment 3

[0034]

[0035]Mix 100ml of water and 3.6g of NaOH, heat up to 70°C, add anthranilic acid (0.03mol, 5.19g), continue to heat up to 80°C, stir until completely dissolved, then cool down to about 50°C, slowly add 8.2g of 20% dilute hydrochloric acid. After the acid analysis is completed, add ice to cool down to below 15°C, then add 2.1g of sodium nitrite, react for about 45min, add 2.0g of ammonium chloride, stir for 15min, and set aside.

[0036] Add 110ml of water and 8.3g of 30% NaOH solution to the reactor, heat up to 60°C, add naphthol AS derivative (0.03mol, 10.29g), continue to heat up to complete dissolution, then cool down to 65°C, filter, and the filtrate Pour into the coupling reactor, and slowly add 4.7g of dilute acetic acid dropwise. After the acid analysis is completed, the pH value is 6.5, add 3g of sodium acetate, stir for 15min, and set aside.

[0037] Add the diazo component to the coupling component slowly and uniformly for about 30 minutes, then continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com