Method for processing phenol-contained tar

A processing method and technology for phenol tar, applied in chemical instruments and methods, preparation of organic compounds, inorganic chemistry, etc., can solve the problems of waste of resources and difficult recovery of phenolic products, save processing costs, improve product yield, The effect of avoiding emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Accurately weighed 1g of phenol-containing tar and 100g of distilled water were placed in a 200ml flask with a condensing device, refluxed for 30 minutes, and then filtered to obtain a tar filtrate. The content of hydroquinone in the tar filtrate was analyzed by liquid chromatography, and the analysis results showed that the content of hydroquinone in the phenolic tar was 12.5%.

[0019] Another sample of phenol-containing tar was taken, and the carbon, hydrogen, and oxygen elements were quantified by an elemental analyzer. The test results showed that the carbon element content in the phenol-containing tar was 65.4%, the hydrogen element content was 3.6%, and the oxygen element content was 30.9%.

[0020] Take 100g of phenol-containing tar (containing 12.5g of hydroquinone), crush it to 20 mesh, raise the temperature from 100°C to 600°C in a carbonization furnace at a rate of 2°C / min, and stay there for 1 hour, while raising the temperature at a rate of 30ml / min. Conti...

Embodiment 2

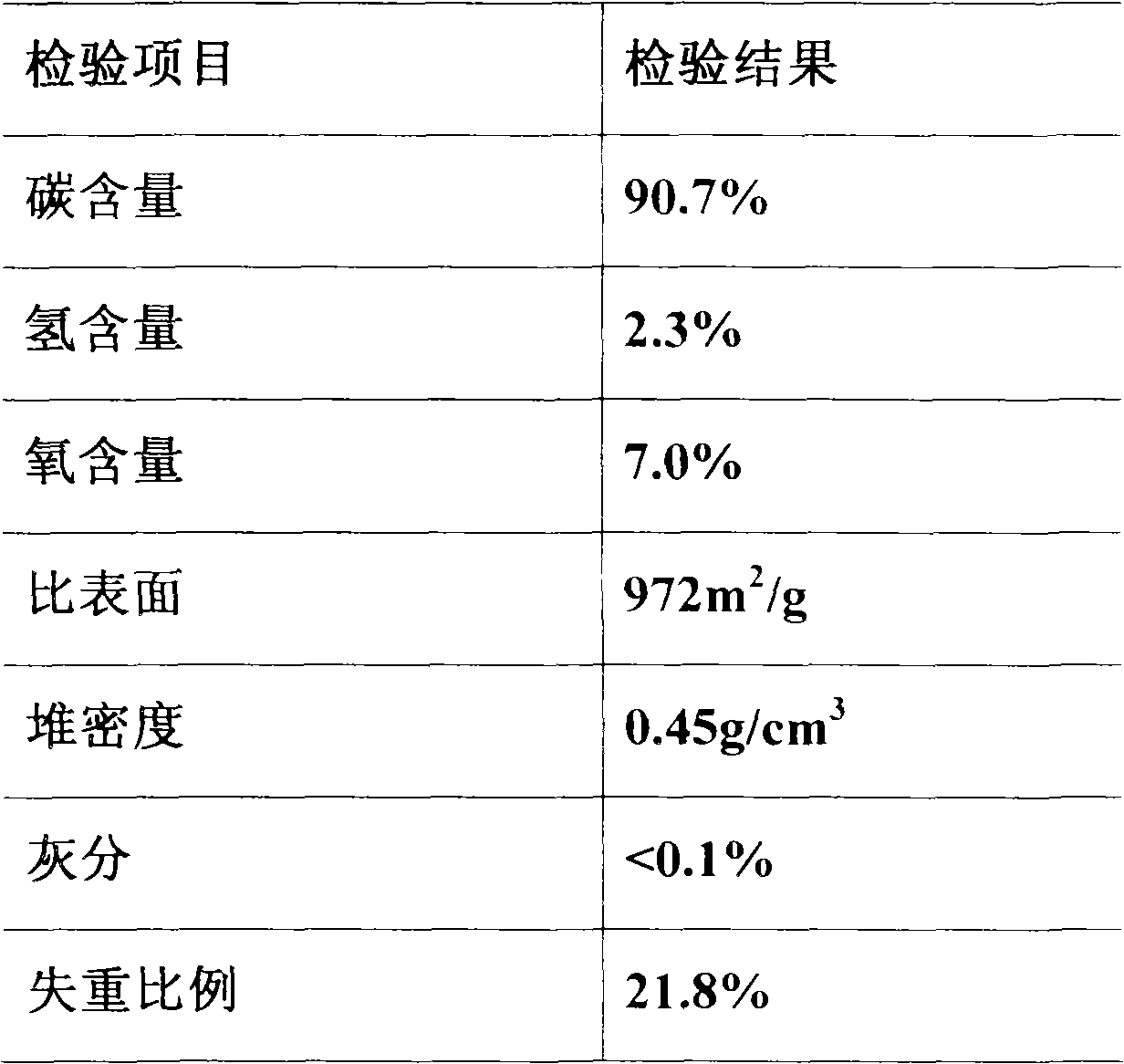

[0024] In addition to taking 100g of phenol-containing tar (containing 12.5g of hydroquinone), the temperature was raised from 100°C to 900°C at a rate of 3°C / min in the carbonization furnace, and stayed for 1 hour. N 2 Carry out purging, the tail gas enters the small spray tower and absorbs the molten state phenol of 60 ℃ as the solvent, other steps and methods are the same as in Example 1; the tail gas is absorbed by the molten phenol solvent, and the recovery rate of hydroquinone is 96.5%. The test results of the carbonized product are shown in Table 2. All indicators meet the requirements of coal-based activated carbon, and the ash content is very small.

[0025] Table 2

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com