Model-based method for loading electro-hydraulic proportional valve

An electro-hydraulic proportional valve and model technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of different correspondence between control current and output pressure, great influence of control accuracy changes, and pressure shocks, etc., to achieve The loading method is simple and easy, the effect of improving the degree of pollution resistance and reducing the cost of control

Inactive Publication Date: 2010-12-01

BEIJING INSTITUTE OF TECHNOLOGYGY +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is a serious non-linearity between the control current and the output pressure of the electro-hydraulic proportional valve, especially the relationship between the two is greatly affected by the flow rate. Under different flow rates, the relationship between the control current and the output pressure Correspondence is also different

When the pressure is closed-loop controlled, it is prone to pressure shock, the control accuracy is greatly affected by the flow change, and the response speed is slow.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a model-based method for electro-hydraulic proportional loading and belongs to the technical field of hydraulic loading technology and automation. The method comprises the following steps: pre-establishing conversion relations between the control current and the pressure of a hydraulic proportion valve at different flow rates, namely models; and selecting a corresponding model according to the actual flow rate to complete the pressure control of the proportion valve. As the different models are adopted under different conditions, the control accuracy is improved greatly.As the established models possibly have certain errors, a feedback compensation process is adopted to eliminate the errors in the models. As a result, the pressure control accuracy of the electro-hydraulic proportional valve is improved, the response time is reduced, and the requirements on pressure, force or torque loading are met.

Description

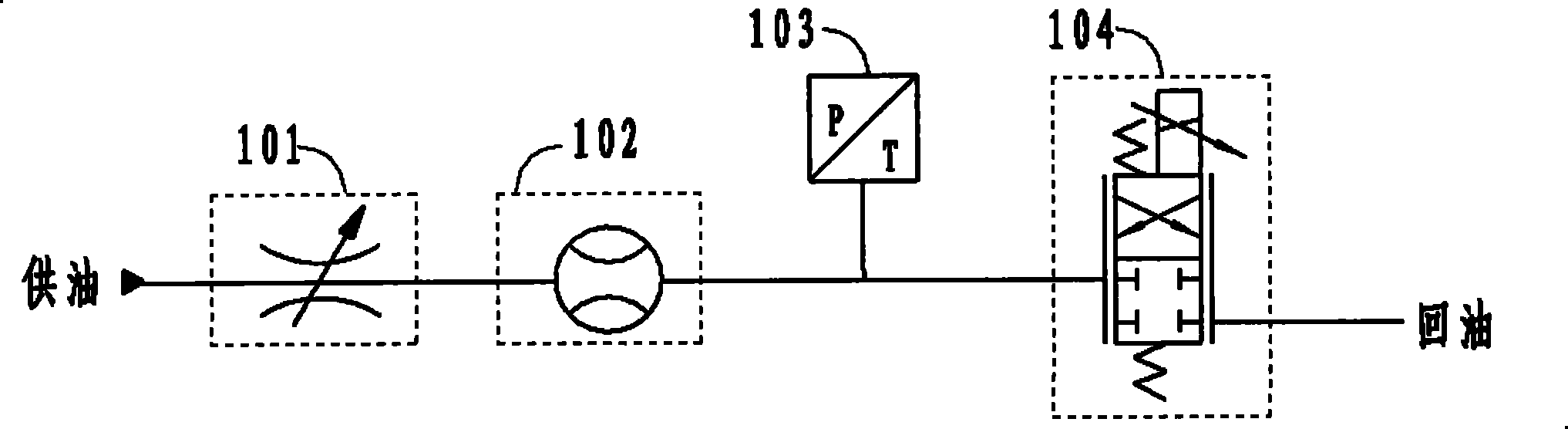

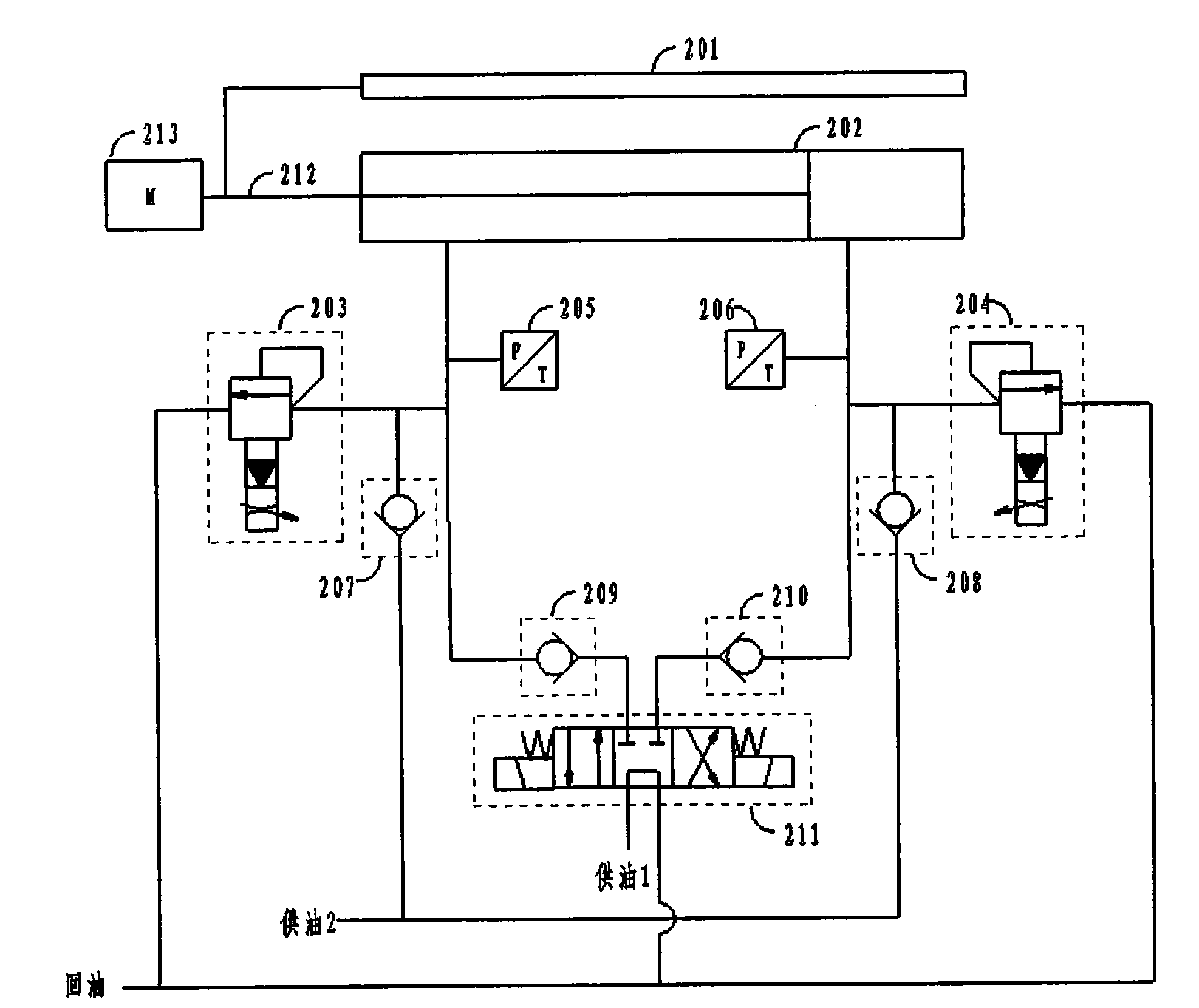

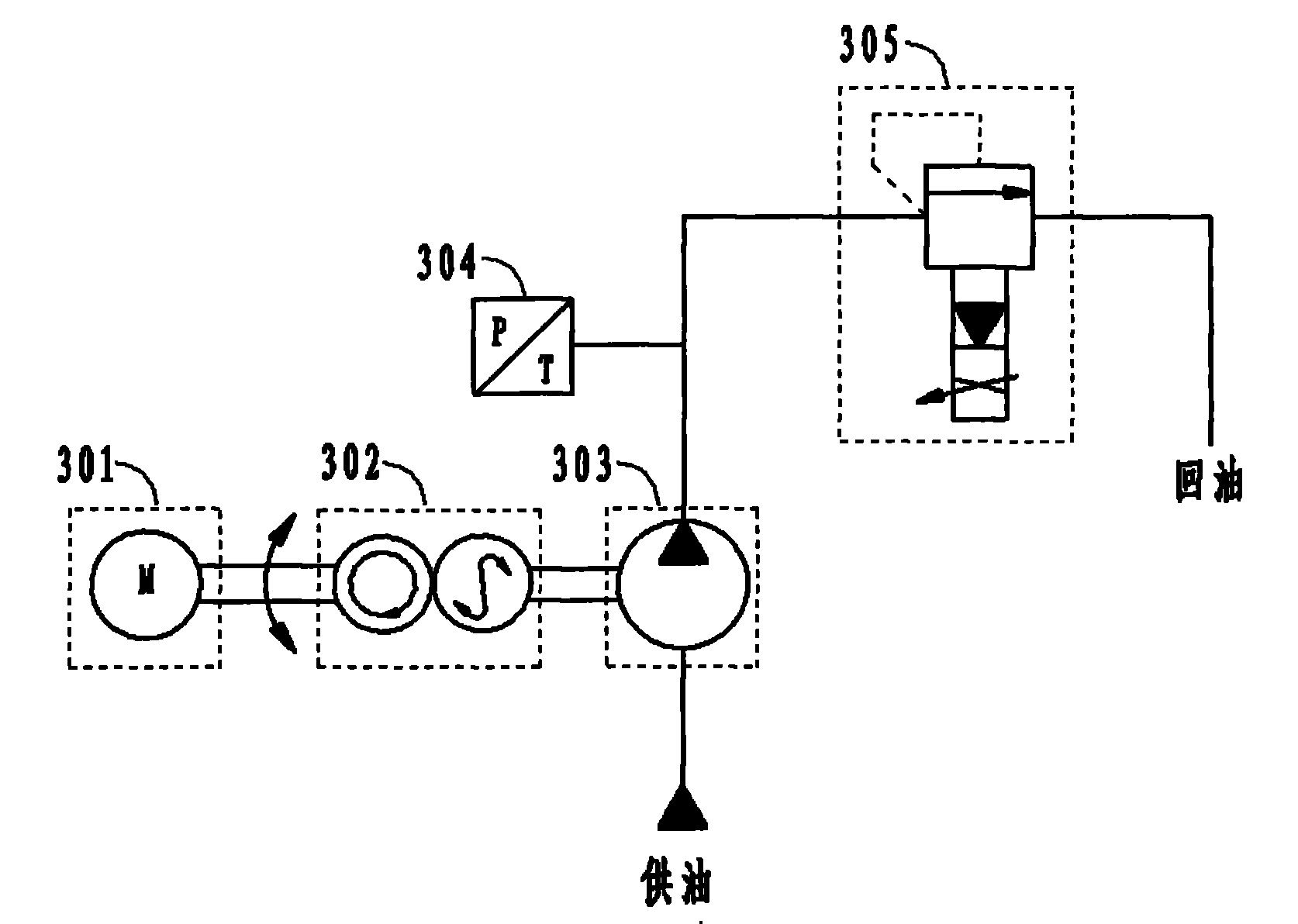

A Model-Based Loading Method for Electro-hydraulic Proportional Valve technical field The invention relates to a model-based electro-hydraulic proportional valve loading method, which belongs to the field of hydraulic loading technology and automation technology. Background technique Hydraulic loading due to its larger power volume compared to electric loading. Therefore, it has been widely used. In terms of loading forms, hydraulic loading can be divided into the following three forms according to different loading objects: pressure loading for hydraulic valves; force loading for linear motion mechanisms through hydraulic cylinders; torque loading for rotary motion mechanisms through hydraulic pumps . The principle of pressure loading for the hydraulic valve is shown in Figure 1. The hydraulic valve 104 is connected to the outlet of the loaded valve 101, and the pressure at the outlet of the loaded valve 101 is controlled by the hydraulic valve 104, so as to complete t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M19/00G01M99/00

Inventor 赵江波王军政

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com