Powder decorative coating and its preparation and construction method

A decorative coating and powder technology, applied in powder coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of humidity regulation and adsorption of harmful substances, poor water resistance, unsuitable for interior wall coatings, and damage to the micro-porous structure of shell powder. To achieve the effect of improving air permeability, improving antibacterial and mildew resistance, and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

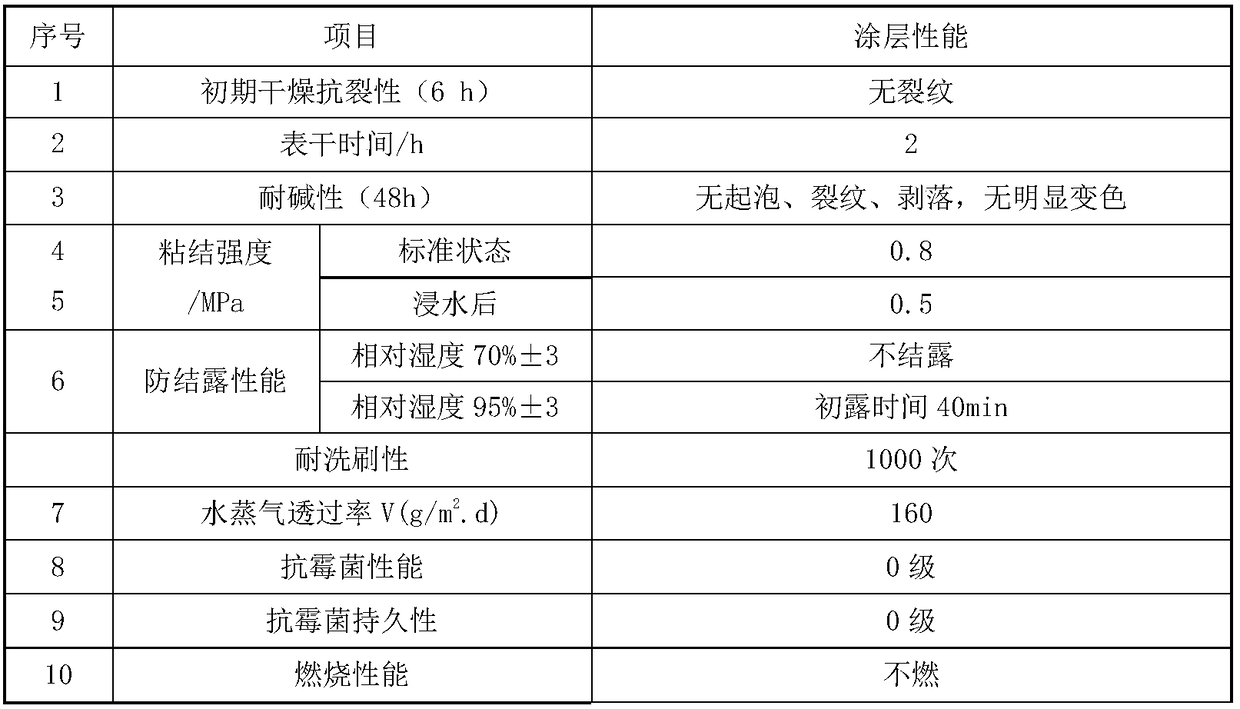

Examples

Embodiment 1

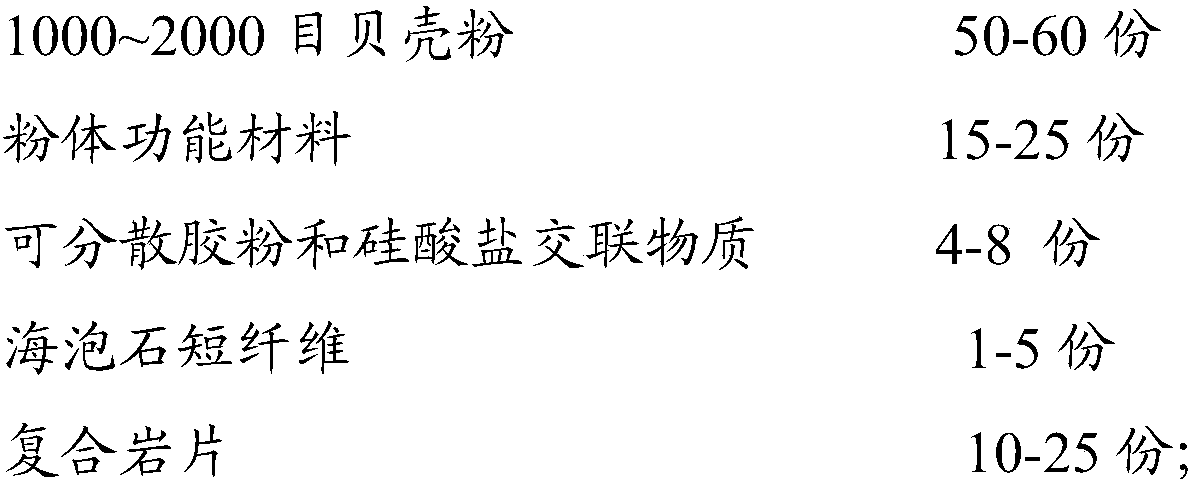

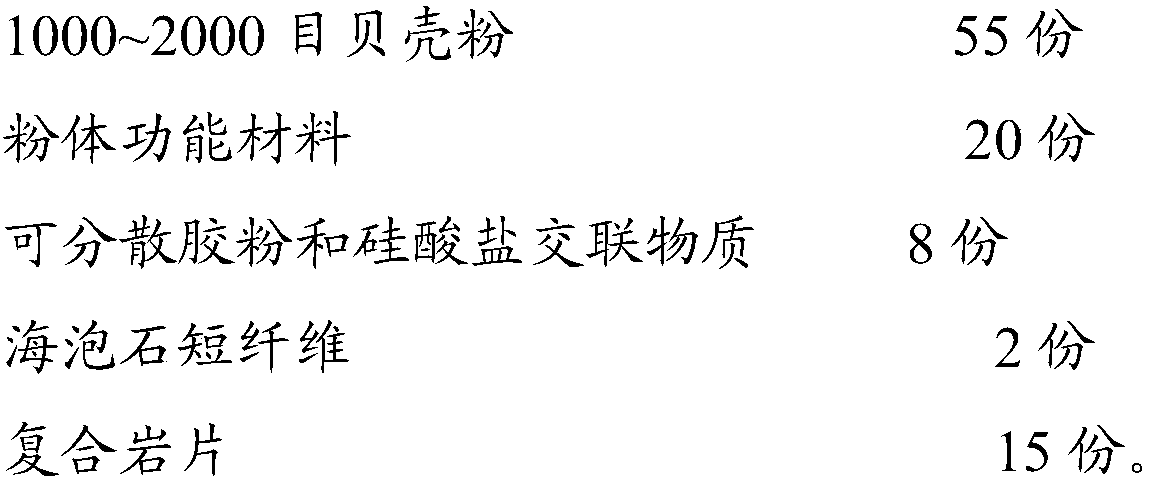

[0048] The proportion of powder decorative coating system is as follows:

[0049] Shell powder 70kg, powder functional filler 10kg (of which attapulgite: 6kg; superfine kaolin 4kg), gray composite rock slice 5kg, powder crosslinking material is vinyl acetate and higher fatty acid vinyl ester copolymer powder 2kg, silicate Cement 8kg, sepiolite short fiber 5kg.

Embodiment 2

[0051] The proportion of powder decorative coating system is as follows:

[0052] Shell powder 60kg, powder functional filler 15kg (of which attapulgite 9kg, superfine kaolin 3kg, flaky sericite powder 3kg), composite rock slice 15kg (gray 10kg, black 5kg), powder crosslinking material is vinyl acetate Homopolymer rubber powder 1kg, Portland cement 7kg, sepiolite short fiber 2.0kg.

Embodiment 3

[0054] The proportion of powder decorative coating system is as follows:

[0055] Shell powder 50kg, powder functional filler 20kg (of which attapulgite 10kg, flake sericite powder 10kg), composite rock flakes 20kg (gray 15kg, blue 5kg, red 5kg), Portland cement 6kg, sea foam Short stone fiber 4kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com