A Pilot Stage Digital Electrohydraulic Servo Valve with Variable Area Gradient

An electro-hydraulic servo valve, digital technology, applied in the direction of servo motor components, multi-way valves, valve devices, etc., can solve the problems of unpredictable valve characteristics, poor anti-pollution ability, large jet tube inertia, etc., to reduce the failure rate , High degree of anti-pollution, uncomplicated model effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

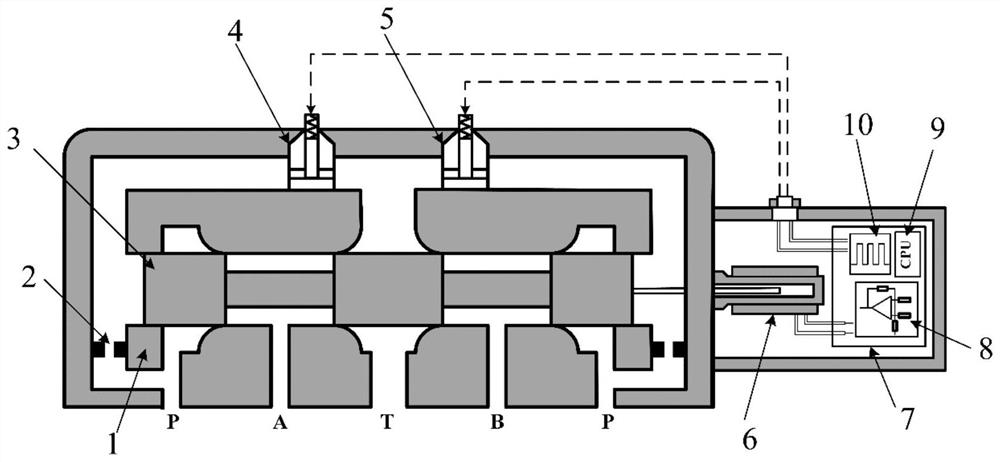

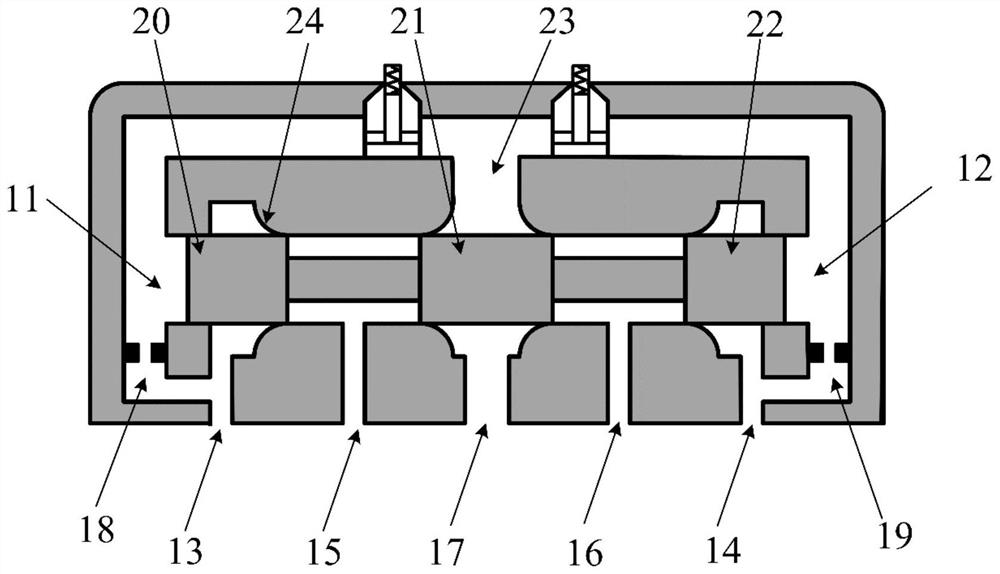

[0040] The present invention provides a pilot stage digital electro-hydraulic servo valve with variable area gradient, which has several improvements:

[0041] One is: the pilot stage adopts two high-speed switching valves of the same model, combined with a digital controller to realize the displacement control of the spool, which not only has good dynamic characteristics, but also improves the anti-pollution ability of the servo valve, thereby reducing the failure rate;

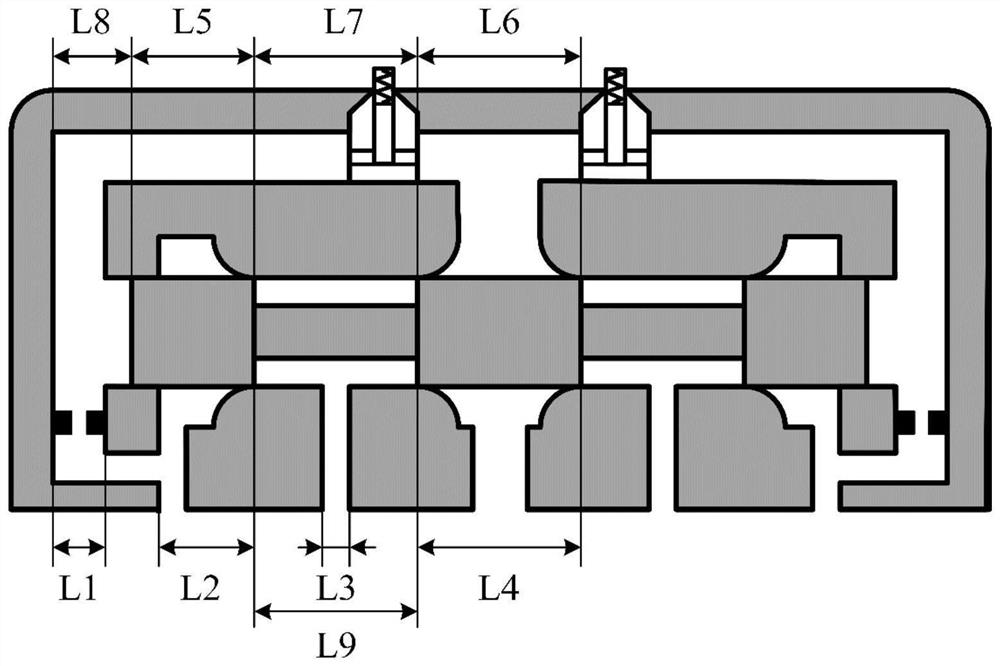

[0042] The second is: through the design of the groove shape of the throttle port of the valve sleeve, the gradient of the throttle port area of the electro-hydraulic servo valve is variable, which improves the zero resolution and flow control accuracy, and at the same time can achieve a larger rated flow rate;

[0043] The third is: the pilot stage adopts the PWM pulse width modulation method to control the high-speed switching valve, and forms a feedback control with the displacement sensor connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com