Glass packaging LED bulb and manufacturing method thereof

A technology of LED bulbs and glass encapsulation, which is applied to lighting devices, components of lighting devices, and damage prevention measures for lighting devices, etc., to achieve the effects of improving manufacturing quality and speed, long-lasting and reliable sealing effects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

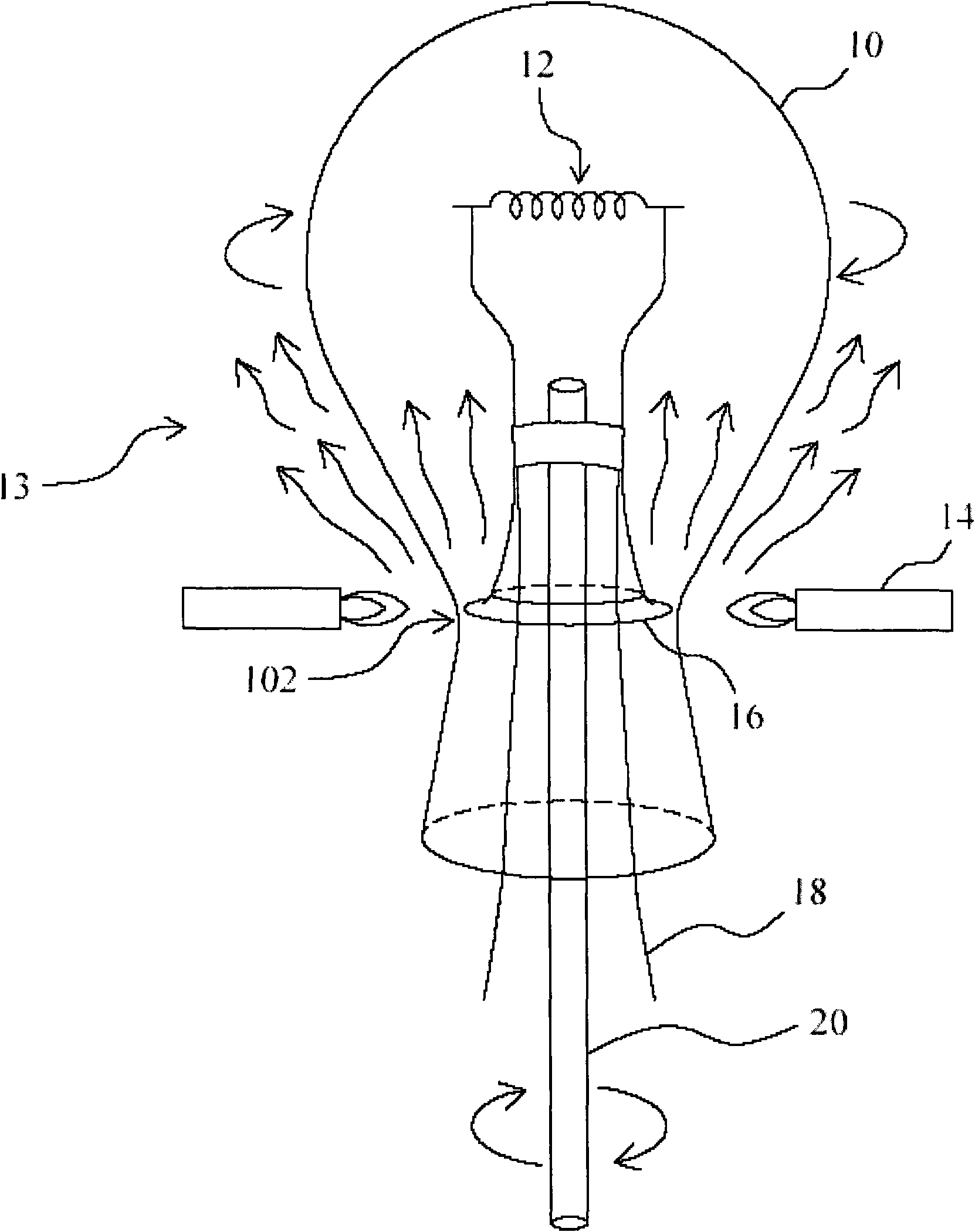

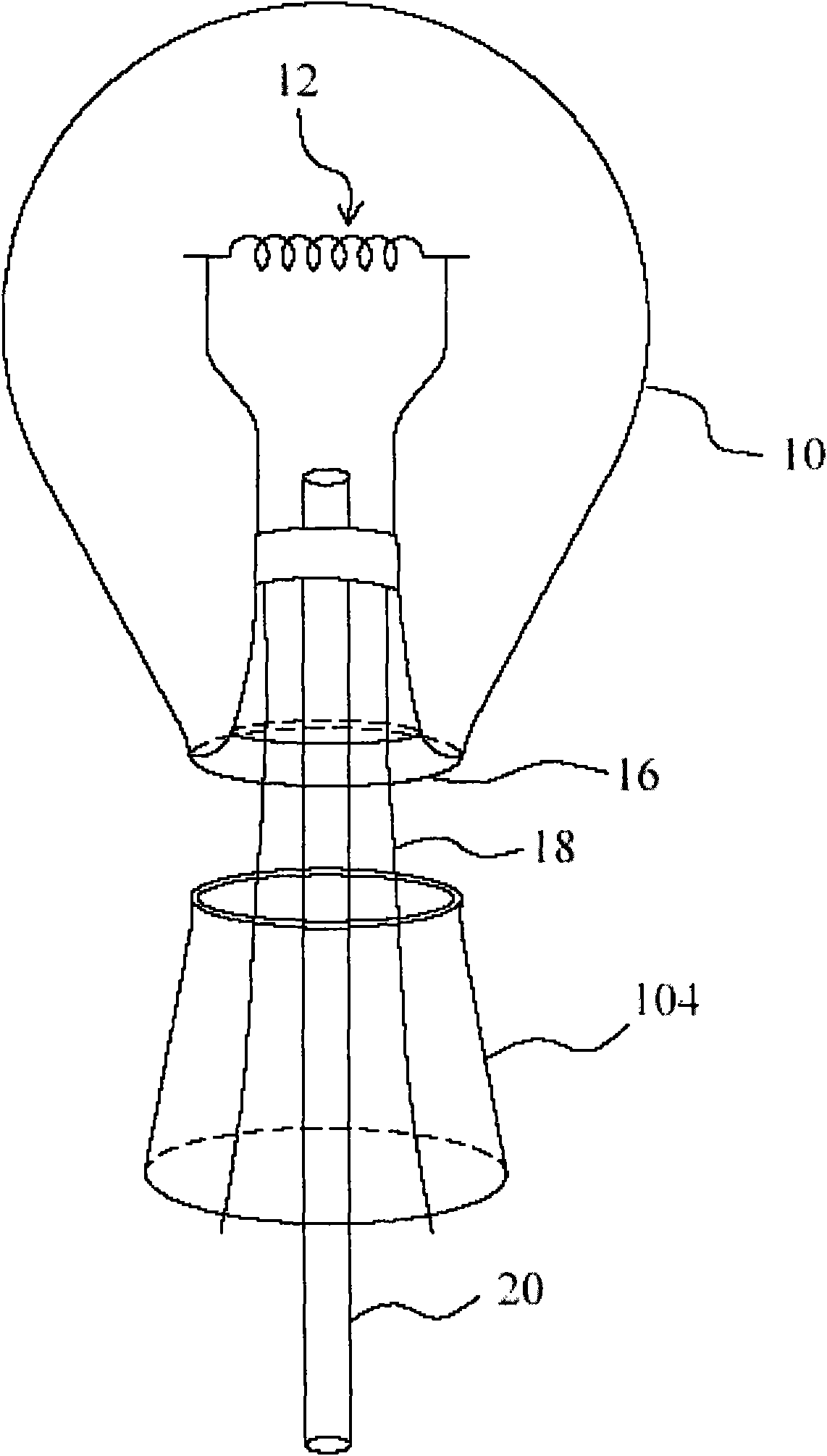

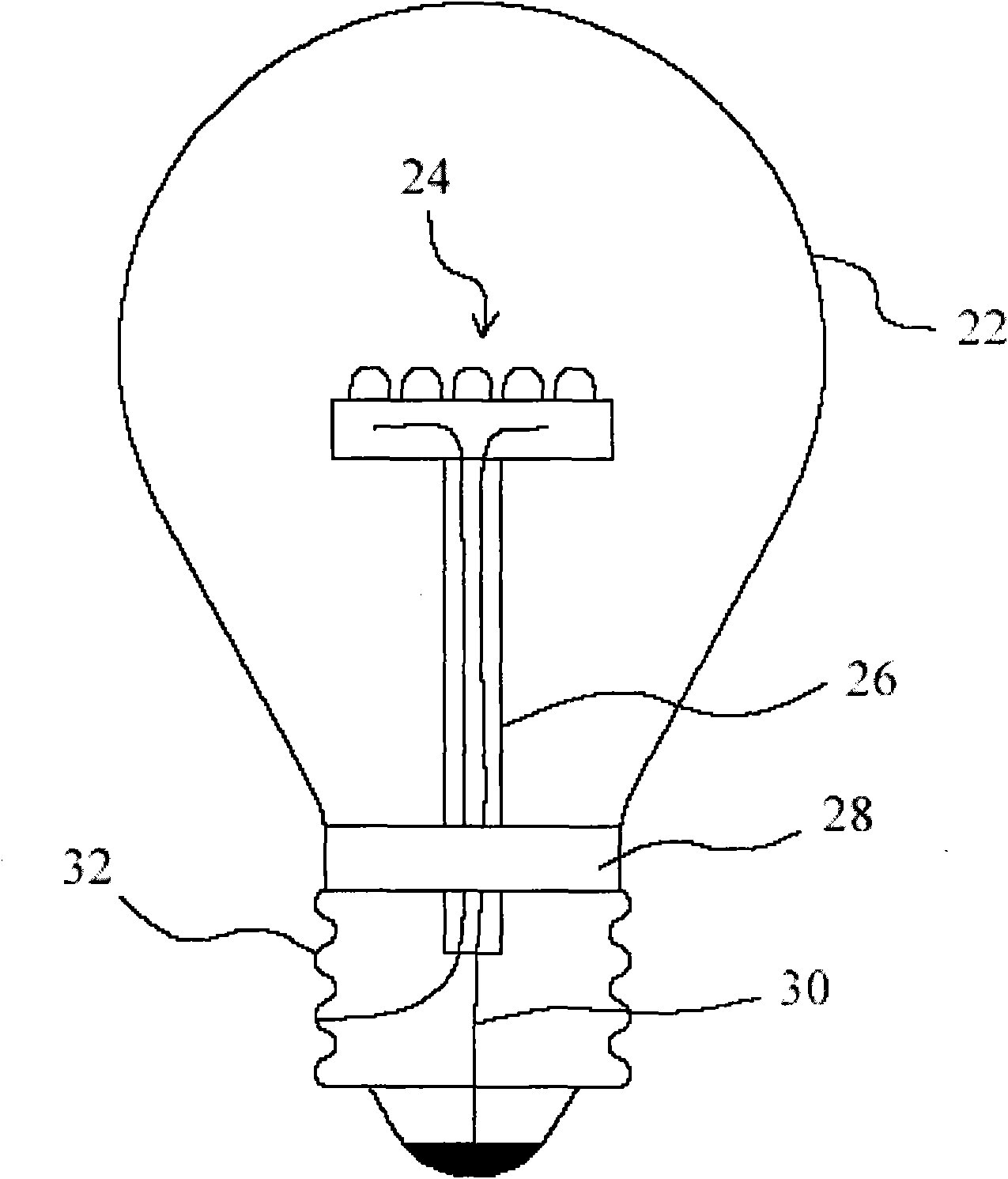

[0067] see now Figure 4 with Figure 5 , Figure 4 It is a schematic diagram of fusion bonding LED bulbs of the present invention, refer to Figure 5 yes Figure 4 Structural drawing of the stem assembly. As shown in the figure, the stem assembly 35 includes an LED wick 36 installed on a support 38, the support 38 can be fixed on the glass horn tube 16 together with an exhaust pipe 20, and the power lead 18 extends from the LED wick 36 Through the glass horn tube 16, the glass horn tube 16 tightly covers the power wire 18, one end of the power wire is electrically connected in series with a temperature control component 37 and the LED wick 36, and the other end extends in the opposite direction to serve as a power supply Connect the power supply lead. With the opening of the glass bulb shell 10 facing upwards, the stem assembly 35 is put into the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com